Rotor assembly and self-starting permanent magnet synchronous reluctance motor

A rotor and assembly technology, applied in synchronous machine parts, electric components, magnetic circuit rotating parts, etc., can solve problems such as high cost, reduced motor output torque and efficiency, and complex control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

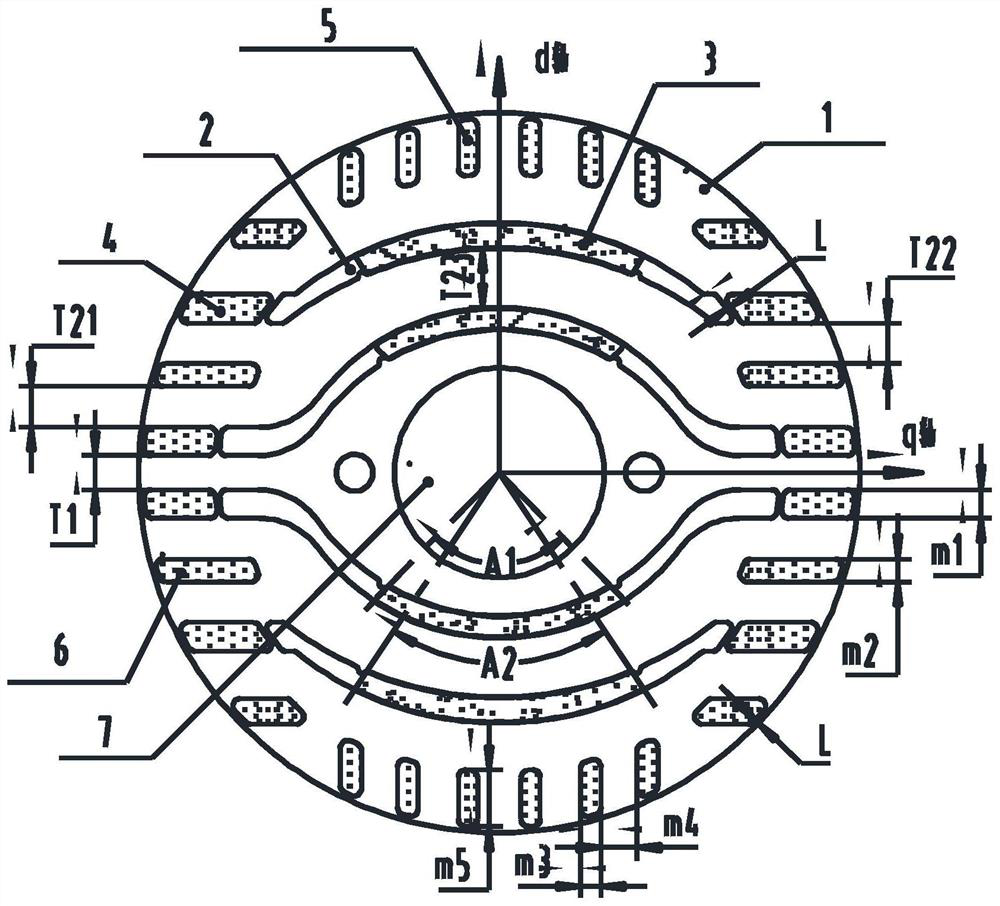

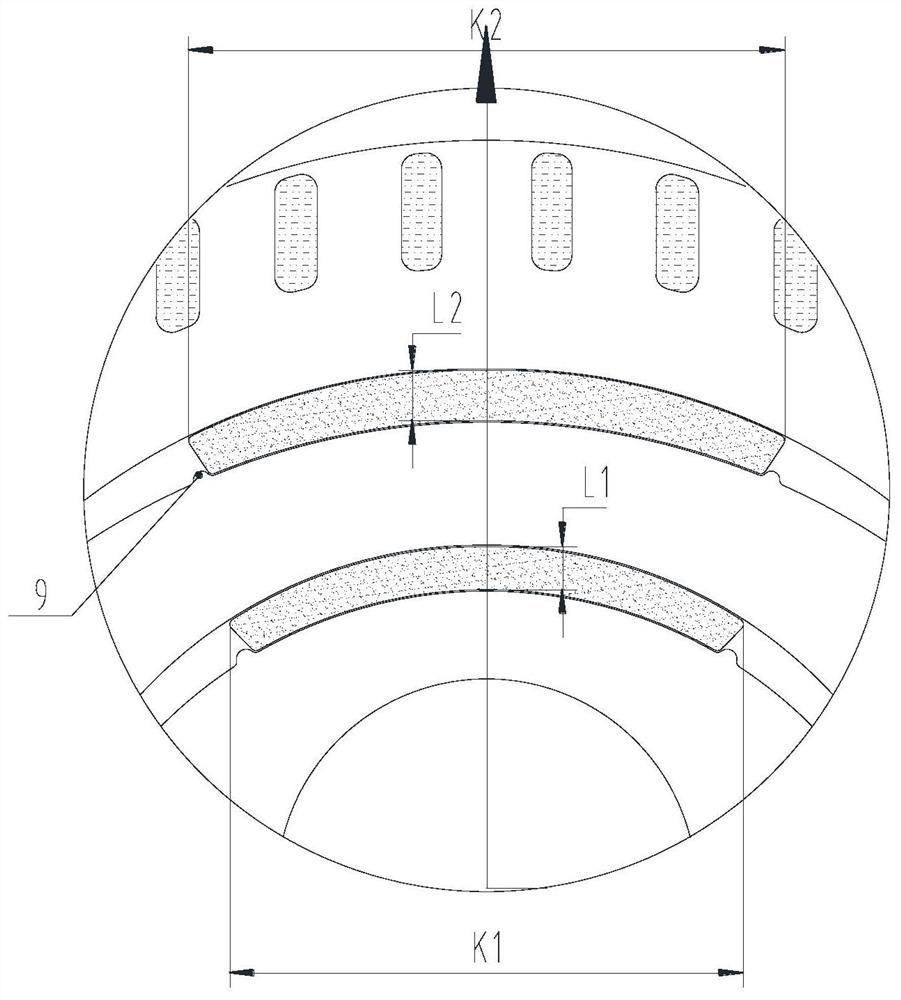

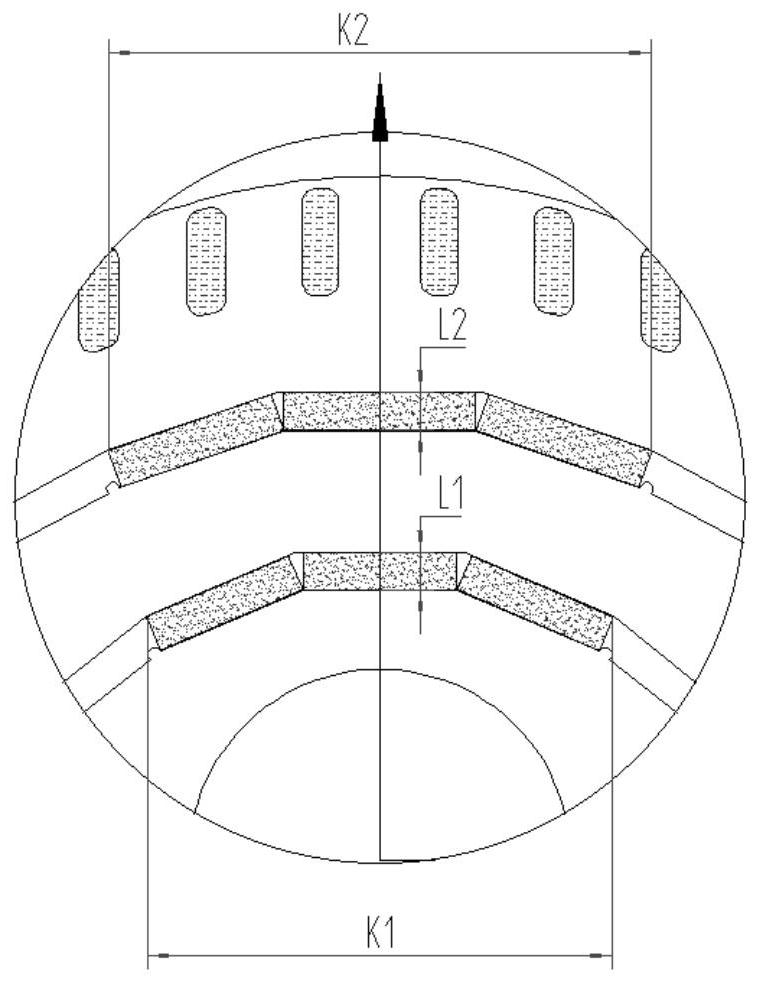

[0032] see in conjunction Figure 1 to Figure 7 As shown, according to the embodiment of the present application, the rotor core 1 is included. On the cross section of the rotor core 1, the rotor core 1 is provided with a shaft hole 7, a slit slot 2, a q-axis squirrel cage slot 4, an independent The squirrel cage 6, the d-axis squirrel cage 5 and the permanent magnet 3, the q-axis squirrel cage 4 are located at both ends of the slit 2, and the independent squirrel cage 6 is set in a misalignment with the slit 2 along the d-axis direction, and the d-axis There are multiple squirrel-cage slots 5, and they are located on the side of the slit slot 2 close to the outer circle of the rotor. The d-axis squirrel-cage slot 5 is set close to the d-axis relative to the q-axis squirrel-cage slot 4 and the independent squirrel-cage slot 6. The permanent magnet 3 Installed in the slit groove 2, the extension direction of the q-axis cage groove 4 and the independent cage groove 6 is parallel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com