Rotor punching sheet structure of permanent magnet synchronous motor for electric motorcycle and rotor thereof

A permanent magnet synchronous motor, rotor punching technology, applied in synchronous machine parts, electric components, magnetic circuits, etc., can solve the problems of poor sinusoidal back electromotive force, large leakage flux of the motor, and small high-efficiency operating area. The effect of increasing motor output torque, increasing motor reluctance torque, and improving field weakening speed expansion capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

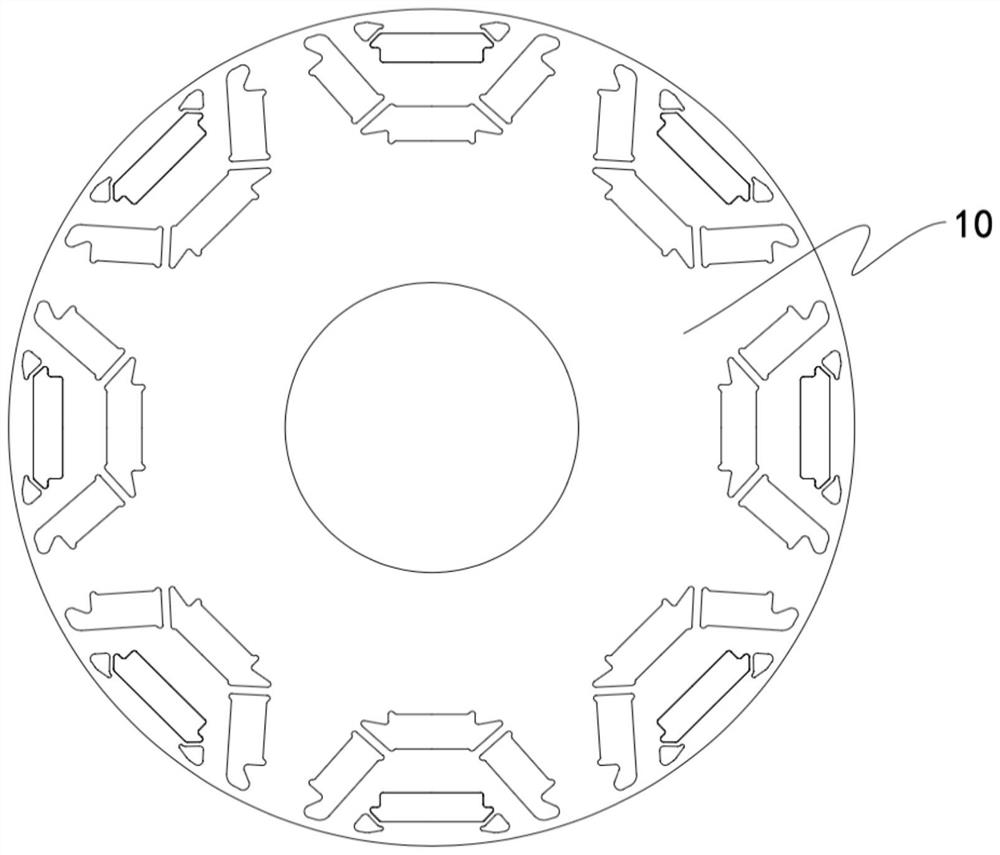

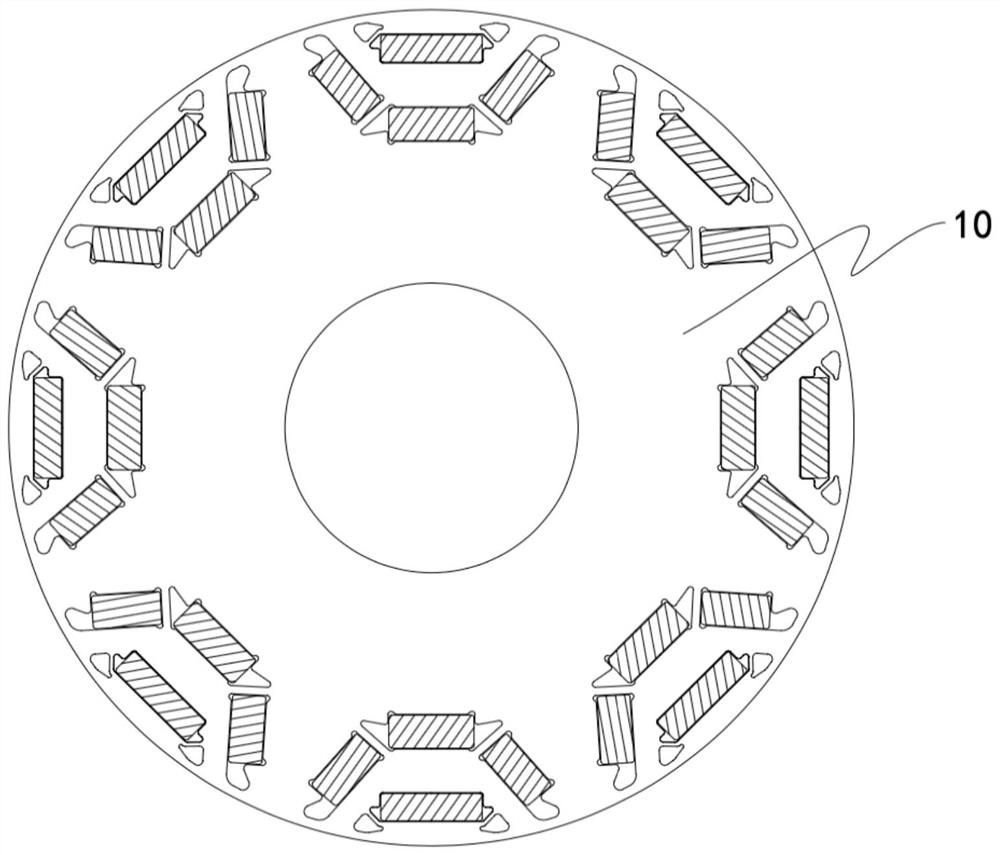

Embodiment 1

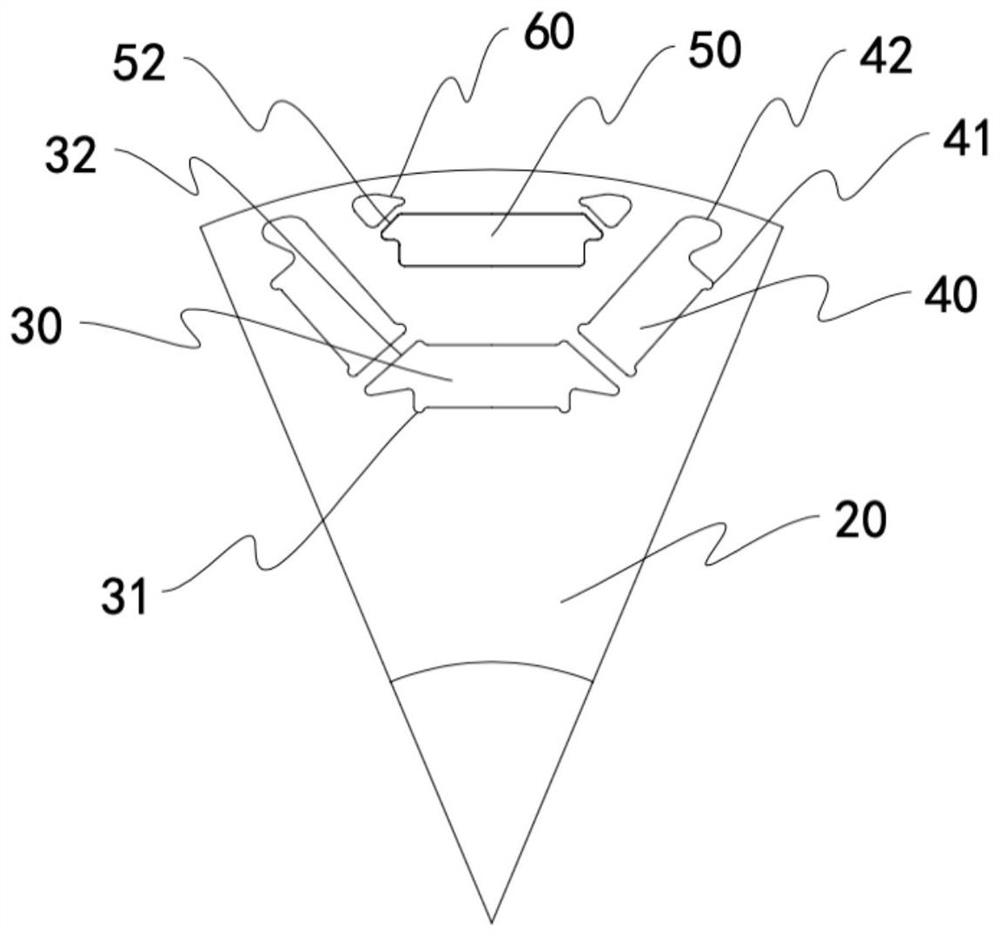

[0026] Such as Figure 1-4 As shown, a permanent magnet synchronous motor rotor punching structure for electric motorcycles includes a punching body 10, and the punching body 10 is divided into a plurality of sectoral areas 20 of equal shape and size, and the sectoral areas 20 are close to the arc edge. A groove group is provided, and the groove group includes an inner layer groove body and an outer layer groove body respectively for installing the magnetic steel 70, and the outer layer groove body is arranged on the side of the inner layer groove body close to the arc edge of the fan-shaped area 20; The inner layer tank body includes an inner layer middle groove 30 and an inner layer side groove 40 arranged on both sides of the inner layer middle groove 30, the inner layer middle groove 30 and the inner layer side groove 40 are all rectangular, the The inner layer middle groove 30 is arranged symmetrically at the center line of the fan-shaped area 20, and the two inner layer ...

Embodiment 2

[0038] This embodiment is basically the same as Embodiment 1, the difference is that the structure of the outer tank body is different, such as Figure 5 As shown, the outer layer tank body in this embodiment includes an outer layer middle groove 50 and outer middle magnetic isolation grooves 52 arranged on both sides of the outer layer middle groove 50, and the outer layer middle groove 50 is rectangular and symmetrical Located at the center line of the fan-shaped area 20, the two corners of the side of the outer layer middle groove 50 near the center of the fan-shaped area 20 are respectively provided with outwardly protruding outer layer middle part convex grooves 51, and the outer layer middle part is convex. The protruding direction of the slot 51 is consistent with the direction of both sides of the outer middle slot 50, and the outer middle magnetic isolation slot 52 is arranged at two corners of the outer middle slot 50 near the arc edge of the fan-shaped area 20, so T...

Embodiment 3

[0041] This embodiment is basically the same as Embodiment 1, the difference is that the structure of the outer tank body is different, such as Figure 6 As shown, the outer tank body in this embodiment includes two outer layer side tanks 60 arranged in a "V" shape and arranged symmetrically with respect to the center line of the fan-shaped area 20. The "V"-shaped opening faces the fan-shaped area 20 arc edge, the outer layer side groove 60 is rectangular, and the two corners of the side edge of the outer layer side groove 60 close to the center line of the fan-shaped area 20 are respectively provided with outwardly protruding outer layer side protrusions. Groove 61, the side of the outer layer side groove 60 away from the center line of the fan-shaped area 20 is provided with an outer layer side convex groove 61 at one end close to the center line of the fan-shaped area 20, the convex groove 61 of the outer layer side convex groove 61 The starting direction is consistent with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com