Dish washing machine with compact structure

A compact and dishwasher-safe technology, applied to tableware washing machines/rinsing machines, tableware washing machines/rinsing and rinsing machine parts, cleaning equipment, etc., can solve the problems of complex waterway design and high cost, and achieve assembly and manufacturing The effect of low process cost, low manufacturing cost and compact design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

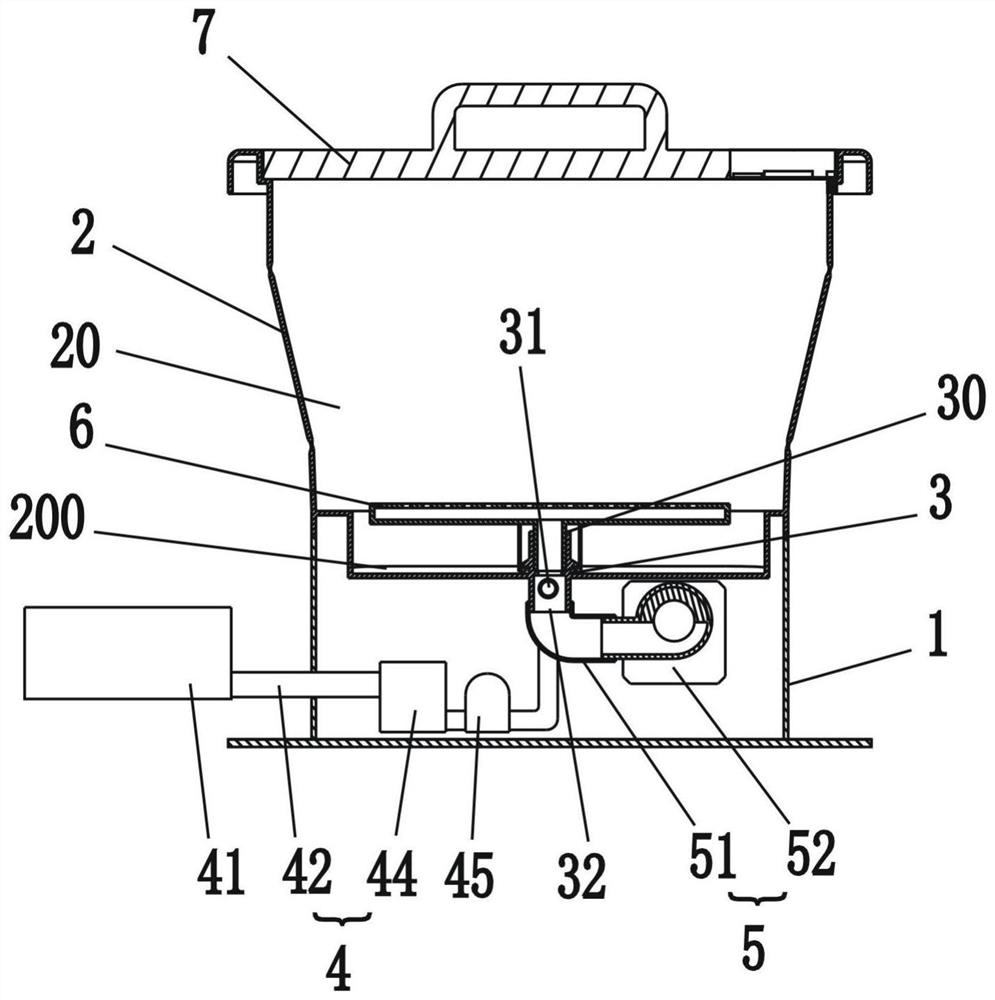

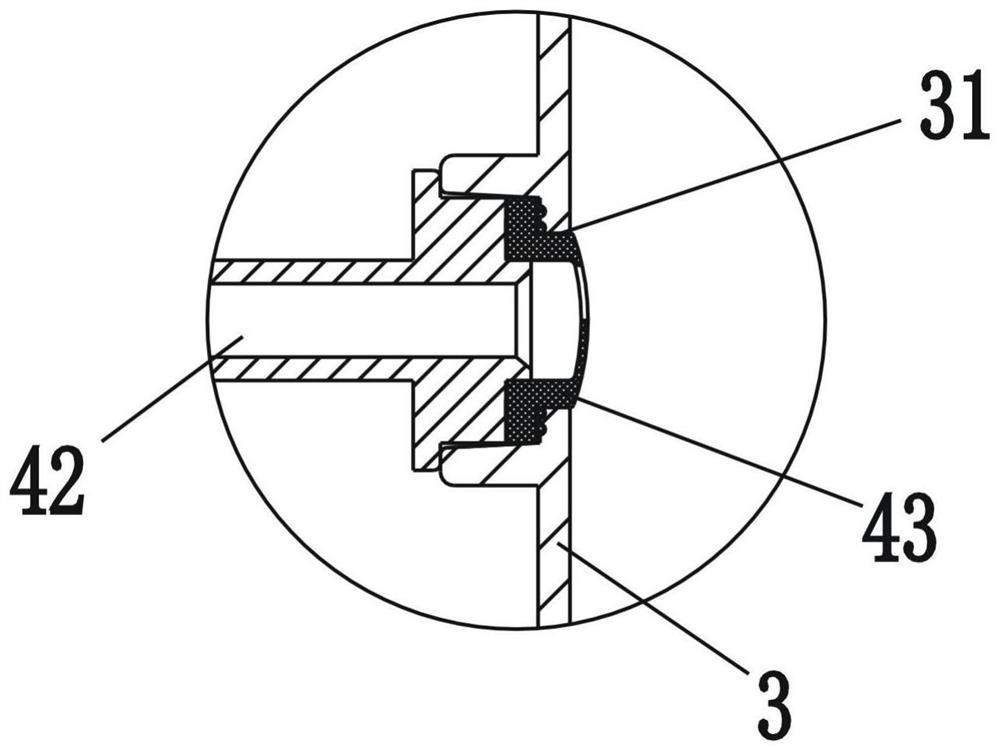

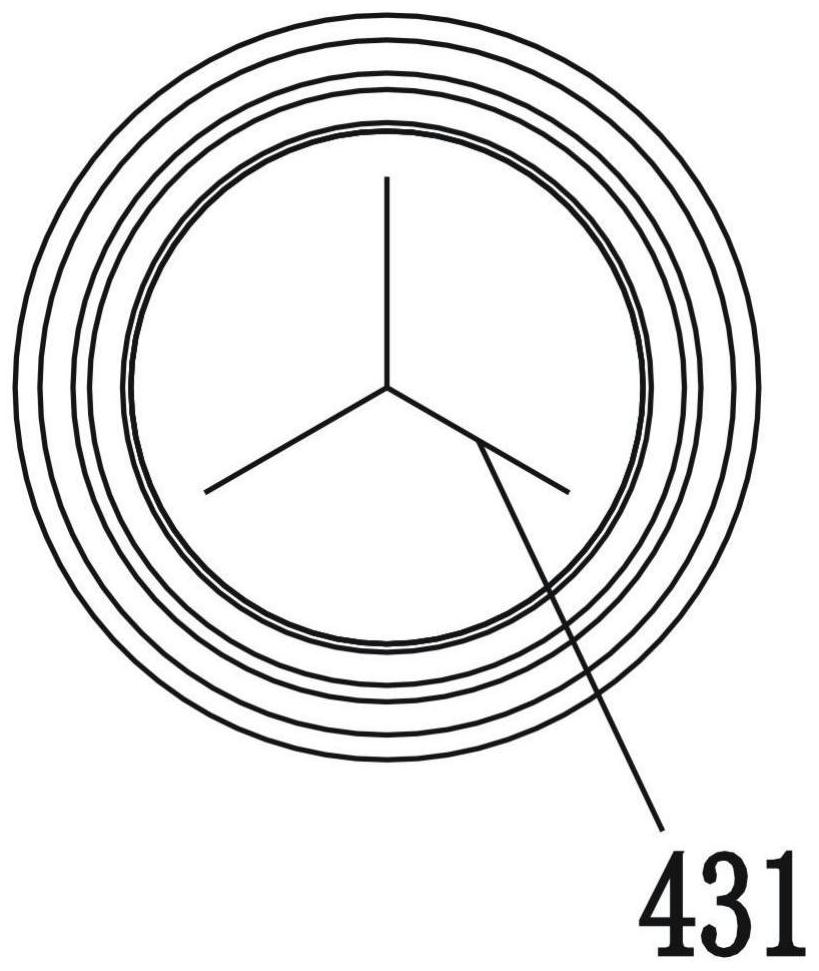

[0036] like figure 1 , figure 2 , image 3 As shown, it is a schematic structural diagram of an embodiment of the dishwasher of the present invention. A dishwasher, comprising a base 1 and a housing 2 mounted above the base 1, a cleaning chamber 20 is formed in the housing 2, and an opening communicating with the cleaning chamber 20 is provided on the upper end of the housing 2, And the cover body 7 is sealed and installed at the opening. Wherein, the bottom of the cleaning chamber 20 is provided with a water collecting tank 200, the bottom of the cleaning chamber 20 is provided with a hollow spray seat 3, and the water outlet 30 of the spray seat 3 is located in the cleaning chamber 20, and sprays The lower part of the shower seat 3 extends into the base 1, the lower part of the shower seat 3 has a first water inlet hole 31 and a second water inlet hole 32, the first water inlet hole 31 is communicated with the water supply system 4, and the first water inlet hole 31 is ...

Embodiment 2

[0042] like Figure 7 , Figure 8 As shown, it is a schematic structural diagram of the second embodiment of the present invention. The difference between this embodiment and the first embodiment is that: in this embodiment, the casing 2 is a foldable structure, which includes a foldable connecting ring 22 and a support ring 23 fixed on the upper end of the connecting ring 22 . The body 2 can be folded through the connecting ring 22. At the same time, in this embodiment, the connecting ring 22 has a structure of large upper and lower small, and the connecting ring 22 includes a hard ring 221 and a flexible ring 222, wherein the hard ring 221 It is integrally formed with the flexible ring 222 .

[0043] At the same time, in this embodiment, an isolation plate 13 is arranged in the base 1, and the isolation plate 13 divides the space in the base 1 into an installation cavity 14 and a water holding cavity 15, wherein the circulating water pump 52, the water pump 44, and the flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com