Hollow fiber positively charged membrane and preparation method thereof

A positive charge and fiber technology, applied in the field of hollow fiber positive charge membrane and its preparation, can solve the problems of complex process, narrow scope of application, unsuitable for large-scale production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

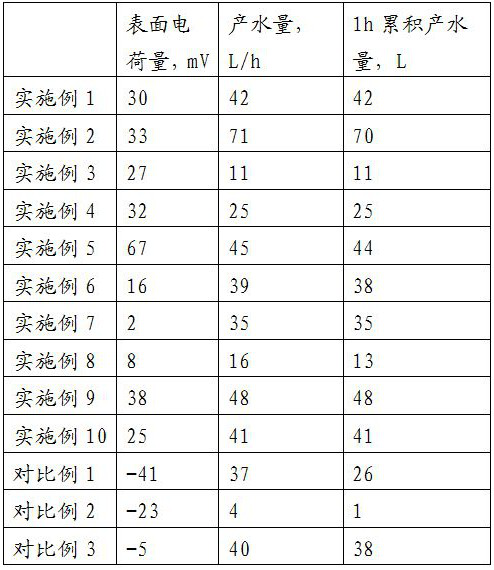

Examples

Embodiment 1

[0019] Example 1: Under nitrogen protection, the active polymer (styrene maleic anhydride random copolymer) 0.3 g, PVDF22G, lithium chloride 3g, and solvent 100g were stirred at 60 ° C for 24 hours, and the cast film was allowed to stand for 24 hours. Liquid, then the cast film liquid and the core fluid are extruded from the hollow fiber spinneret to the coagulation bath to obtain a hollow fiber load containing a bare amino group; wherein the core liquid is RO water to add 10 g / l Trivadic four Amine, 30 ° C. The coagulation bath is RO water, 30 ° C; wherein the styrene maleic anhydride random copolymer is prepared by the following steps: with a nitrogen protection, styrene, maleic anhydride and anhydride duisine is sequentially added in dimethylacetamides. Nitrile, three substance molar ratios were stirred at 1: 1: 0.003, 60 ° C for 10 hours, resulting in the product.

Embodiment 2

[0020] Example 2: 30 ° C The core is RO water. The coagulation bath was 10 g / l Trivadic Tuqua RO water, 30 ° C. The rest is the same as in Example 1.

Embodiment 3

[0021] Example 3: The material is polysulfone, and the rest is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com