Paste recycling device

A recovery device and batter technology, which is applied in the fields of dough processing, baking, food science, etc., can solve the problems of unsatisfactory modernization, time-consuming and labor-intensive problems, and achieve the effects of reducing labor intensity, improving efficiency, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

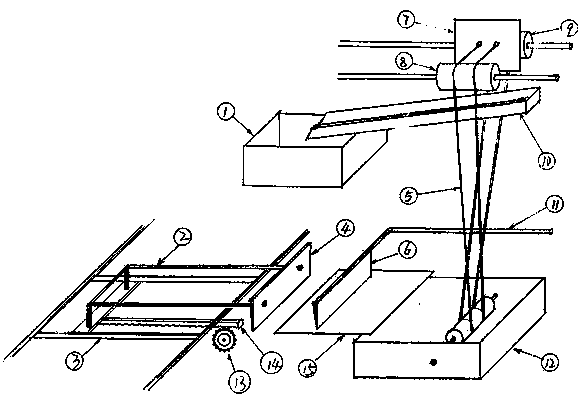

[0019] see figure 1 , in an embodiment of the present invention, a batter recycling device includes a batter hopper 1, a driving shaft, an auxiliary driving shaft, a linear slide rail 3 and a recycling batter hopper 12, a driving wheel 9 is installed on the driving shaft, and the auxiliary driving shaft The first auxiliary driving wheel 8 is installed on the shaft, and the recovery paste bucket 12 is provided with the second auxiliary driving wheel. There is a paste board 7, a guide groove 10 is arranged below the paste board 7, the left end of the guide groove 10 is arranged above the paste bucket 1, a push rod slide bar 2 is arranged on the linear slide rail 3, and the push plate slides The right end of the rod 2 is equipped with a push plate 4, the lower end of the push plate slide bar 2 is provided with a rack 14, the underside of the rack 14 is meshed with a driving gear 13, and the upper left end of the recovery paste bucket 12 is provided with a recovery receiving plate...

Embodiment 2

[0026] On the basis of the first embodiment, the gluing plate 7 is provided with diversion grooves. It is convenient to guide and discharge the batter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com