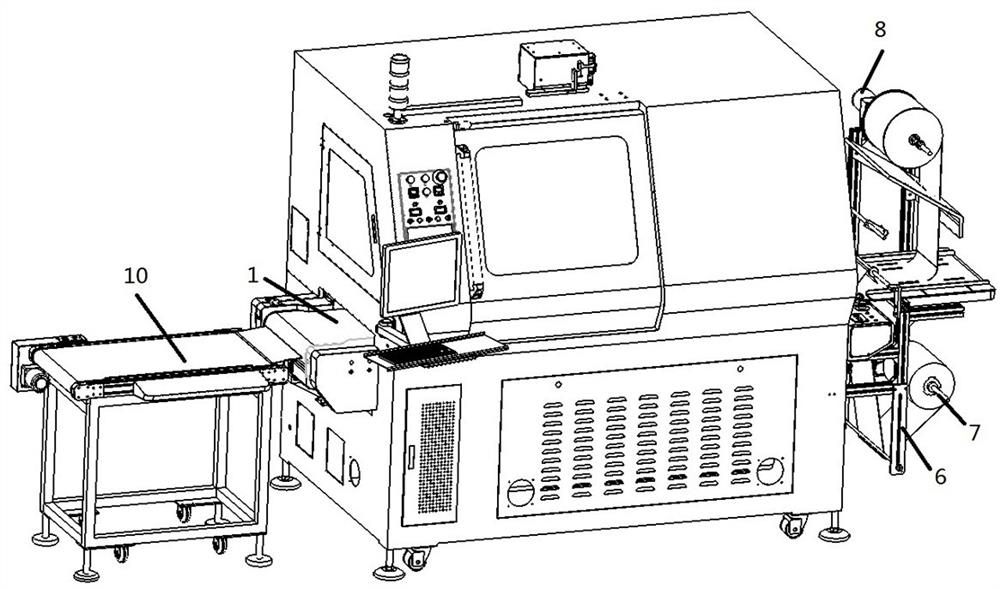

Double-station lace cutting machine

A cutting machine and double-station technology, applied in the direction of welding/welding/cutting items, manufacturing tools, metal processing equipment, etc., can solve the problems of large labor force and low production efficiency, and achieve the effect of solving large labor force and reducing joint processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

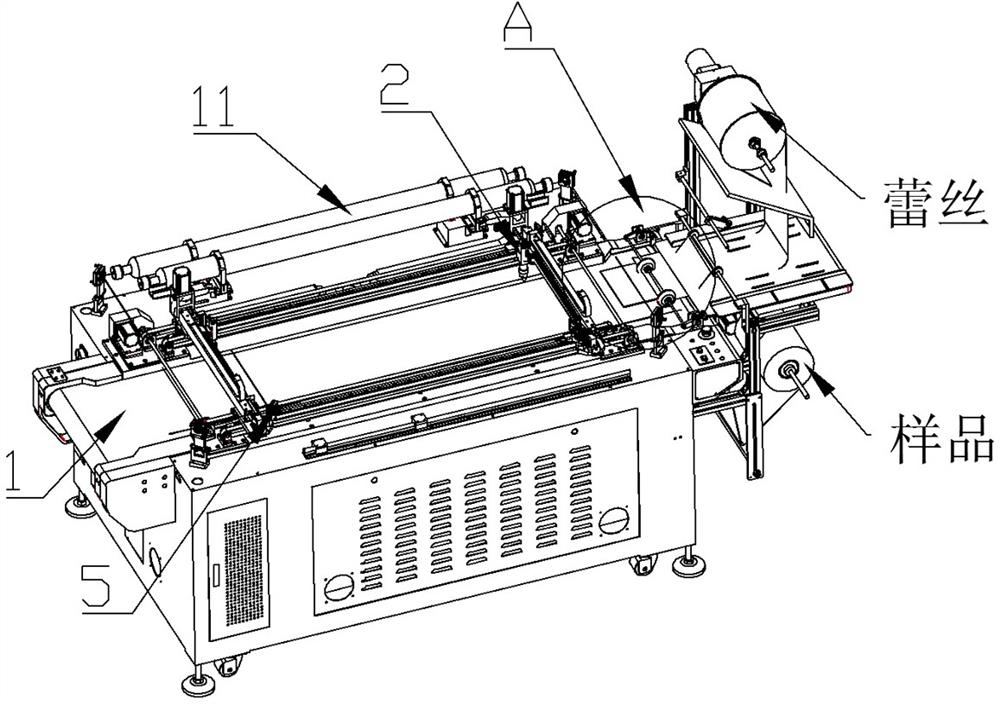

[0024] see Figure 1-4 As shown, the present invention relates to a double-station lace cutting machine, the cutting machine body is used to cut lace samples, it is characterized in that, comprising:

[0025] The table part 1 has a placement surface on which the cloth is placed and moves linearly in a certain direction;

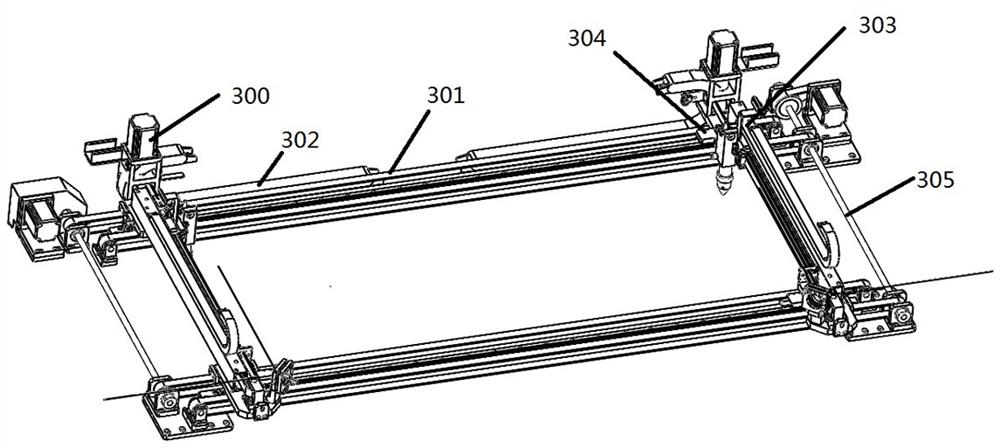

[0026] The cutting part 2 is configured with a multi-axis displacement platform, and the multi-axis displacement platform is installed outside the table part 1 so that the cutting range of the cutting part 2 can be extended to the whole of the lace sample;

[0027] The projection part 4 projects the image on the cloth in the way of front projection, and the cutting part 2 irradiates the lace with a high-power-density laser beam to cut and make a specific pattern.

[0028] The beneficial effects of the present invention are: the working range of the cutting part 2 is limited to the table part 1 by using a multi-axis displacement platform, and the projection p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com