Mechanical arm auxiliary milling and shot blasting combined machining device

A compound processing and robotic arm technology, applied in the field of mechanical processing, can solve the problems of reducing the processing efficiency of parts, wasting time, wasting labor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

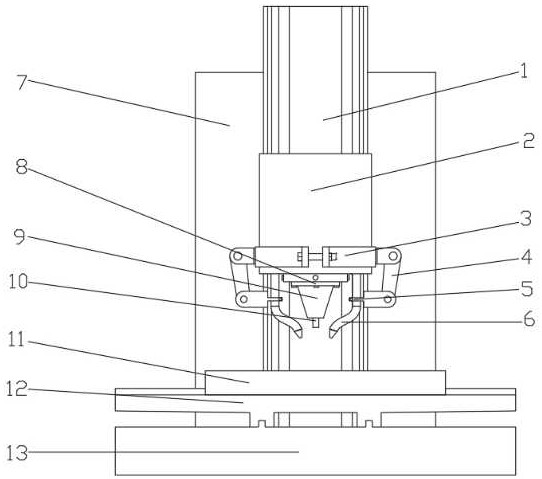

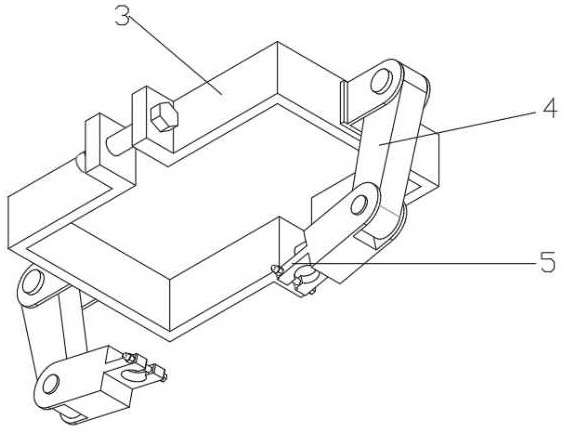

[0023] Examples of the present invention are figure 1 and figure 2 As shown, the present invention includes CNC axis Z-axis (1), milling machine spindle box (2), mechanical arm base (3), mechanical arm (4), fixture (5), shot blasting tube (6), shot blasting machine main body (7), milling machine spindle (8), milling cutter holder (9), milling cutter (10), CNC axis Y axis (11), CNC axis X axis (12), milling machine base (13). When the machine tool is working, the base of the mechanical arm (3) fixes the mechanical arm (4) on both sides of the spindle box (2) of the milling machine, and the operator adjusts the distance and Angle, and each side of the milling cutter is followed by a shot peening tube (6) to ensure that the shot peening tube (6) is always on the rear side of the milling cutter (10) and on one side for shot blasting when the milling cutter (10) is reciprocating. Finally, the machining work on the parts is completed simultaneously with the milling cutter (10). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com