An automatic waste removal type flat indenter tangent device

An automatic cleaning and tangent technology, used in metal processing and other directions, can solve the problems of waste falling around or inside the machine, and the waste is difficult to clean, so as to improve the efficiency of tangent and perforation, improve the efficiency of cleaning, and improve the efficiency of collection and processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

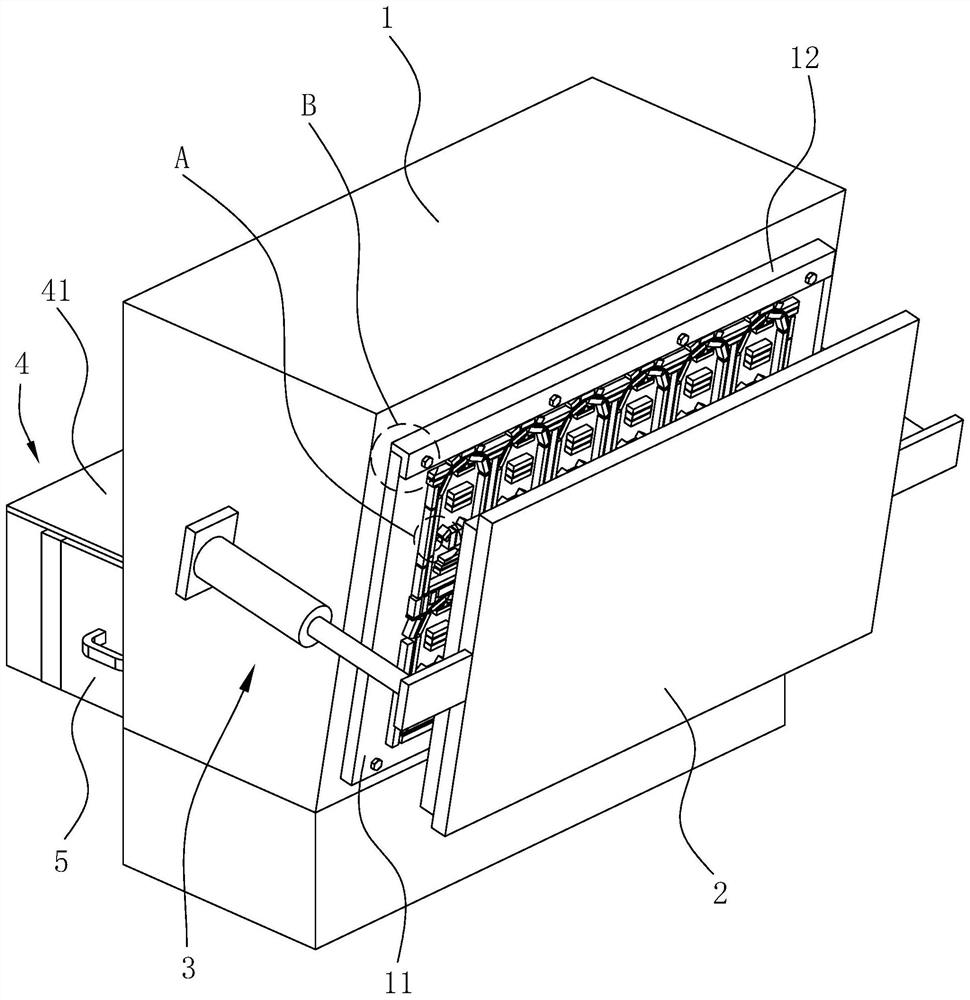

[0037] Attached to the following Figure 1-5 This application will be described in further detail.

[0038] The embodiment of the present application discloses a tangent device of an automatic waste removal type flat indenter.

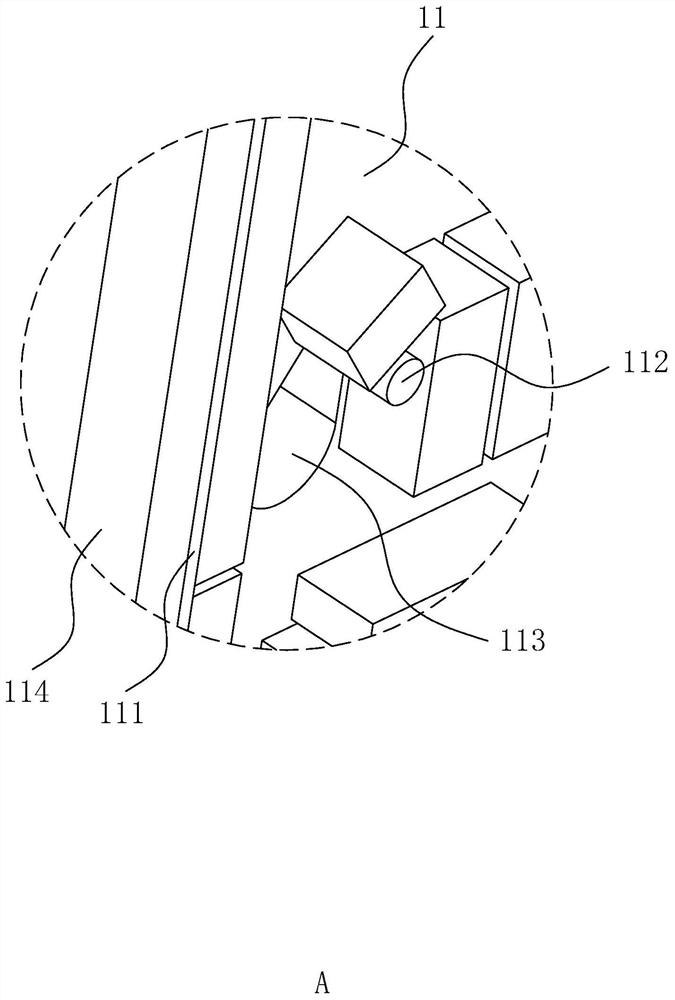

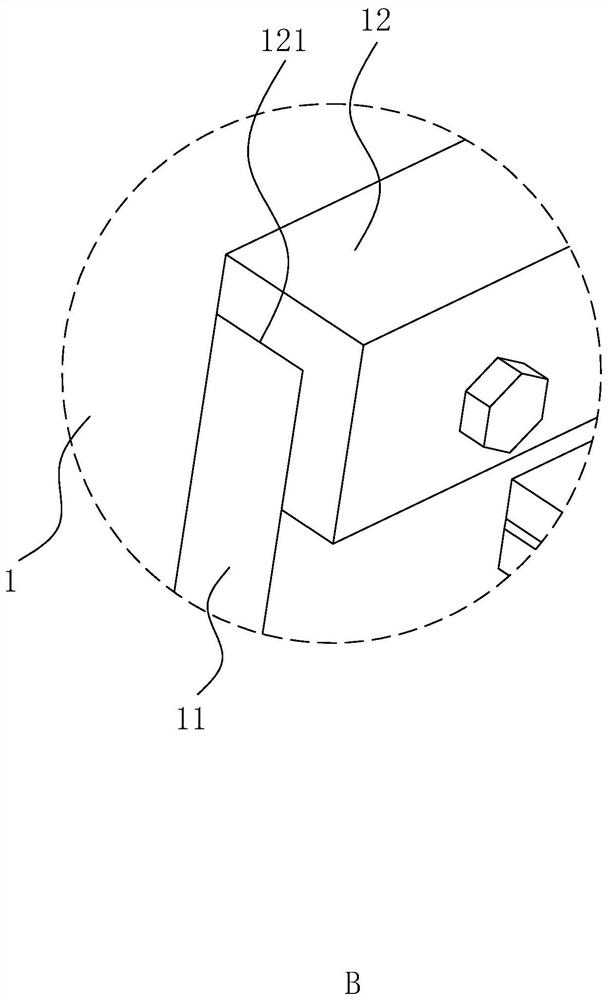

[0039] refer to figure 1 and figure 2 , an automatic waste removal type flat creasing tangent device includes a machine base 1 arranged obliquely and a feeding plate 2 parallel to the machine base 1, the side wall of the feeding board 2 close to the machine base 1 is inclined upward, and the machine base 1 A cutter plate 11 is fixed on the side wall close to the feeding plate 2, and a number of cutting blades 111 and perforation columns 112 are fixed on the side wall of the cutting plate 11 close to the feeding plate 2; The feeding board 2 is close to or away from the drive assembly 3 of the cutting board 11, and the side of the machine base 1 is provided with an exhaust air assembly 4 that collects the waste generated by the perforated column 112 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com