Belt winding and arranging device

A technology of belt unscrambling and fixing seat, which is applied in the directions of coiling strips, thin material handling, transportation and packaging, etc. It can solve the problems of pinch roll flattening, complex structure, and increased equipment manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

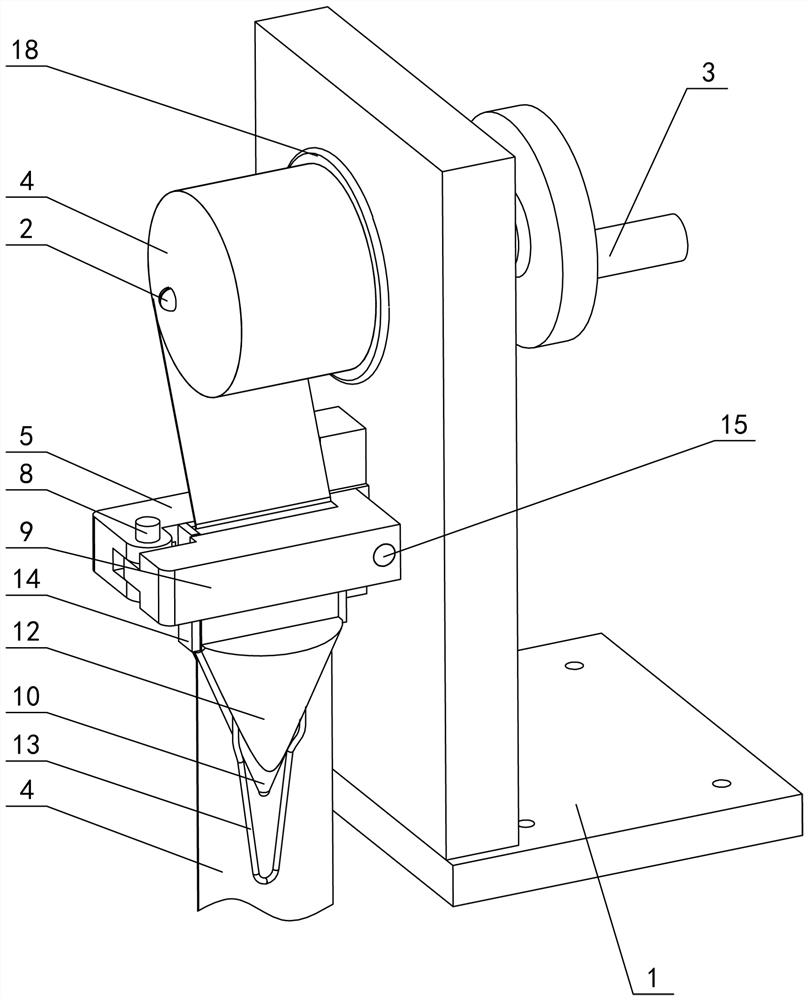

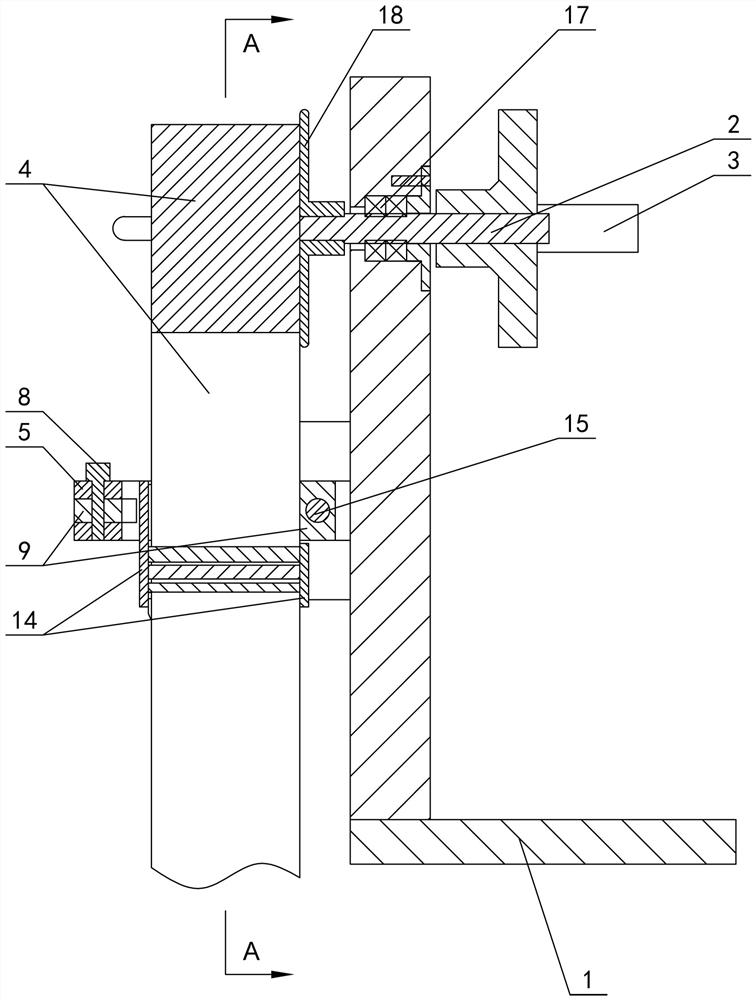

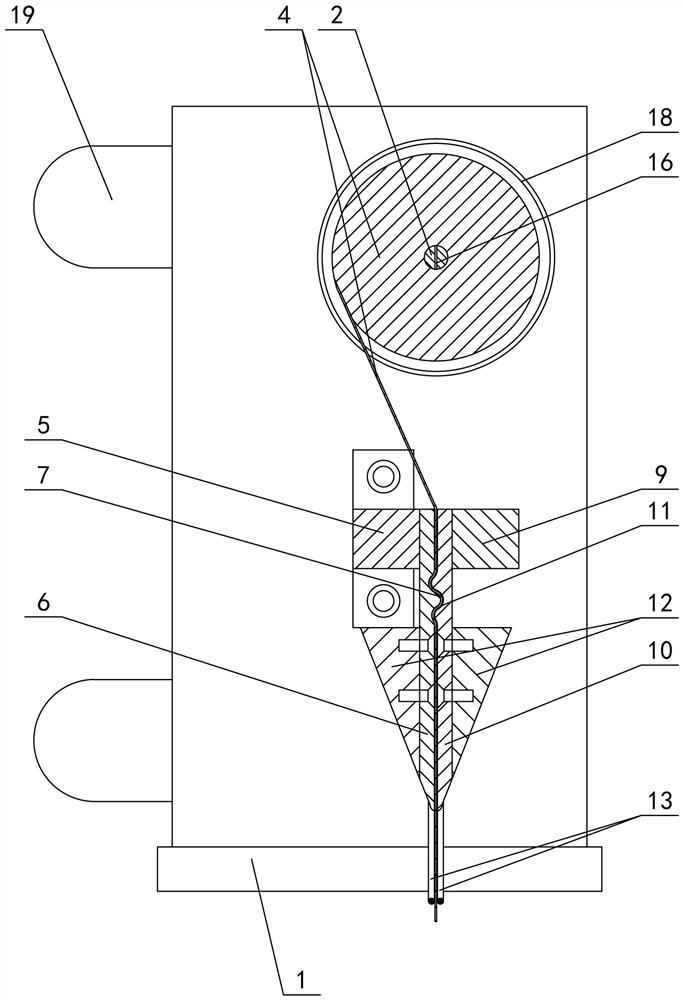

[0020] The invention relates to a tape unwinding device, such as figure 1 — Image 6 As shown, it includes a fixed seat 1, a rotating shaft 2 is arranged in the fixed seat, one end of the rotating shaft is connected to the rocker 3, and the other end of the rotating shaft passes through the fixed seat to cooperate with the belt 4 to be wound, and one side of the fixed seat 1 is set Fixed entrainment seat 5, the fixed entrainment seat is fixed with the fixed seat through fasteners, the fixed entrainment seat is provided with a fixed tape head 6, the top of the fixed tape head is fixed with the fixed entrainment seat, and the inner wall of the fixed tape head is shaped on the first wave Shape lines 7, the lower part of the fixed tape head is conical, one side of the fixed entrainment seat 5 is connected to the rotating entrainment seat 9 through the pin 8, the other side of the rotating entrainment seat cooperates with the fixed entrainment seat through the locking structure, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com