Plugging structure of tower crane hole and construction method thereof

A construction method and technology for openings, which are applied in the processing of building components, building structures, building materials, etc., can solve the problems of affecting the flatness of the floor slab and low efficiency, and achieve the effect of improving the construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

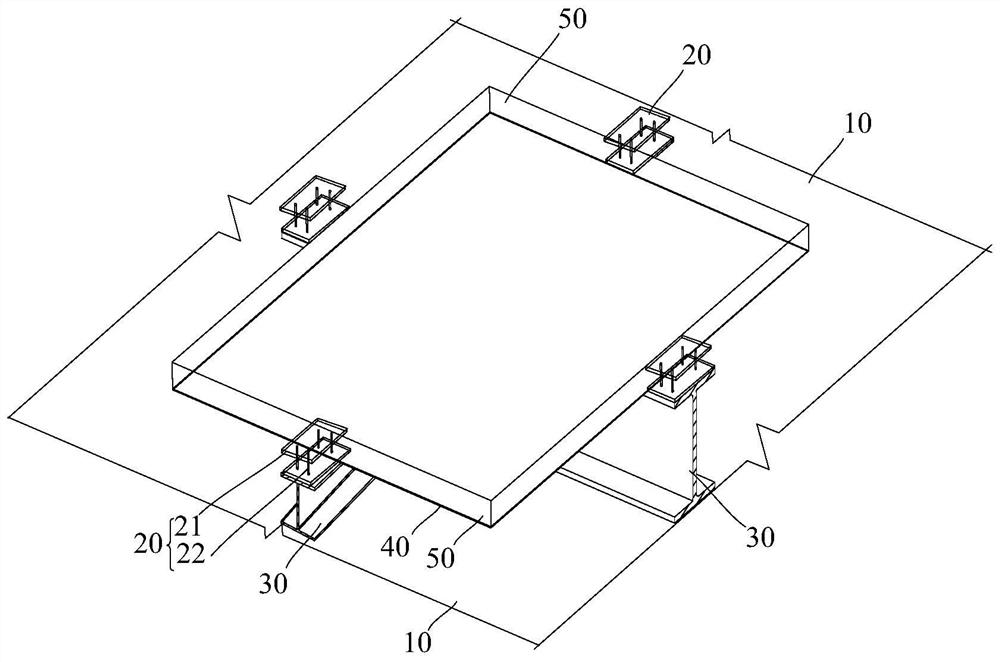

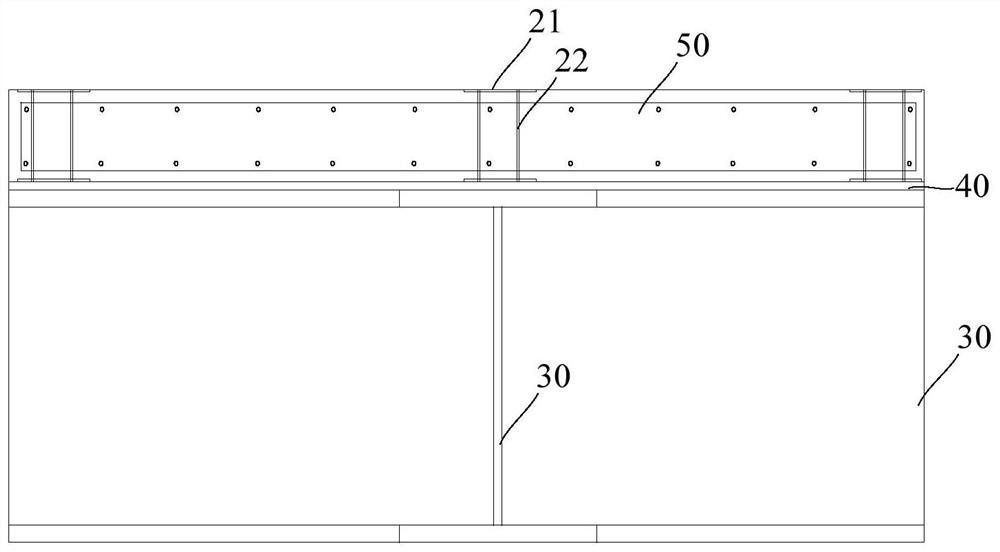

[0046] As a preferred embodiment of the plugging structure of the tower crane opening of the present invention, the embedded part 20 includes: two buried plates 21 arranged up and down and horizontally, the buried plate 21 located above is embedded in the floor 10, and the buried plate located below 21 is attached to the bottom surface of the floor 10, and the top of the support frame 30 is fixedly connected to the buried plate 21 below; the connecting rod 22 is vertically connected to the two buried plates 21.

[0047] Specifically, the connecting rod 22 and the two buried plates 21 are fixedly connected by perforation welding to form an integrated structure, which enhances the firmness and stability of the whole. The upper buried plate 21 is buried in the floor 10 for fixing, and the lower buried plate 21 is attached to the bottom surface of the floor 10 for welding and fixing with the support frame 30 to provide a fixed point for the support frame 30 .

[0048] As a preferr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com