A prefabricated decorative wall convenient for dry construction

A dry construction and prefabricated technology, applied in the direction of wall, covering/lining, construction, etc., can solve the problem that wall decoration is difficult to meet modular decoration, and achieve the effect of improving flatness and reducing possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

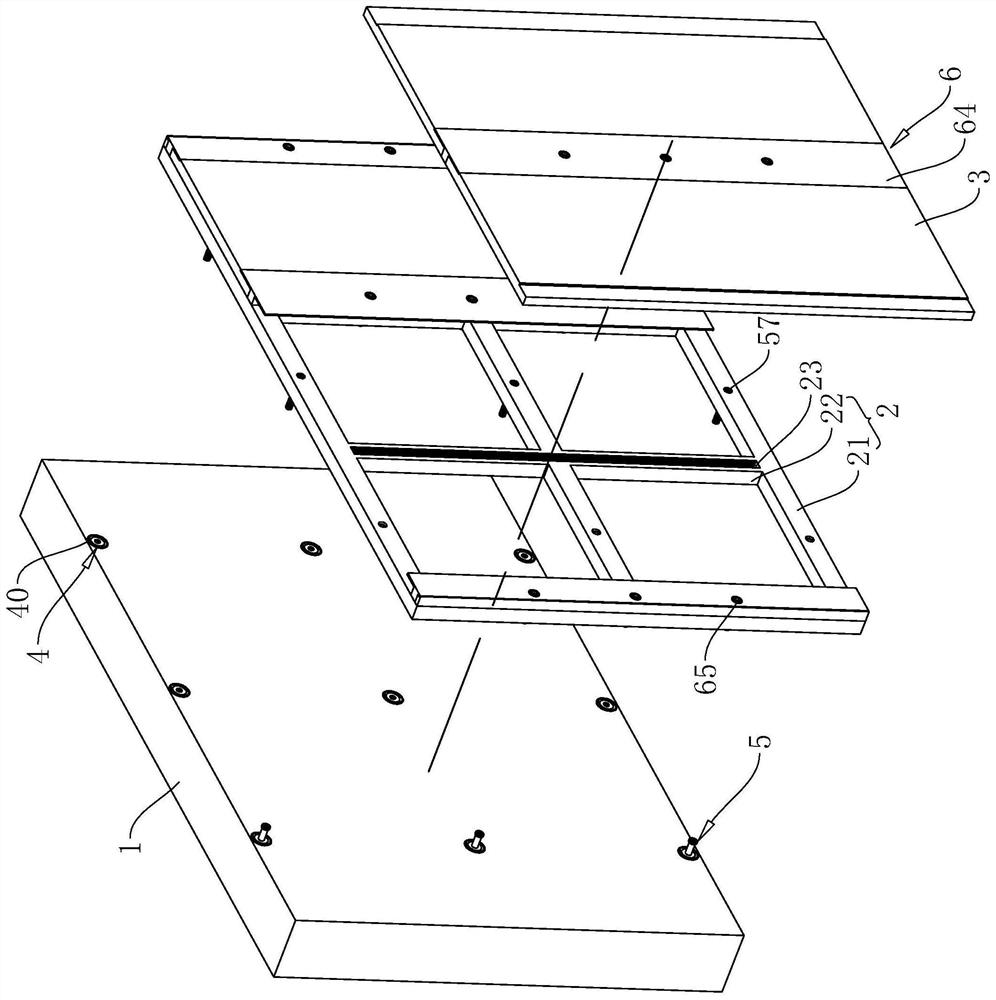

[0042] The following is attached Figure 1-6 The application is described in further detail.

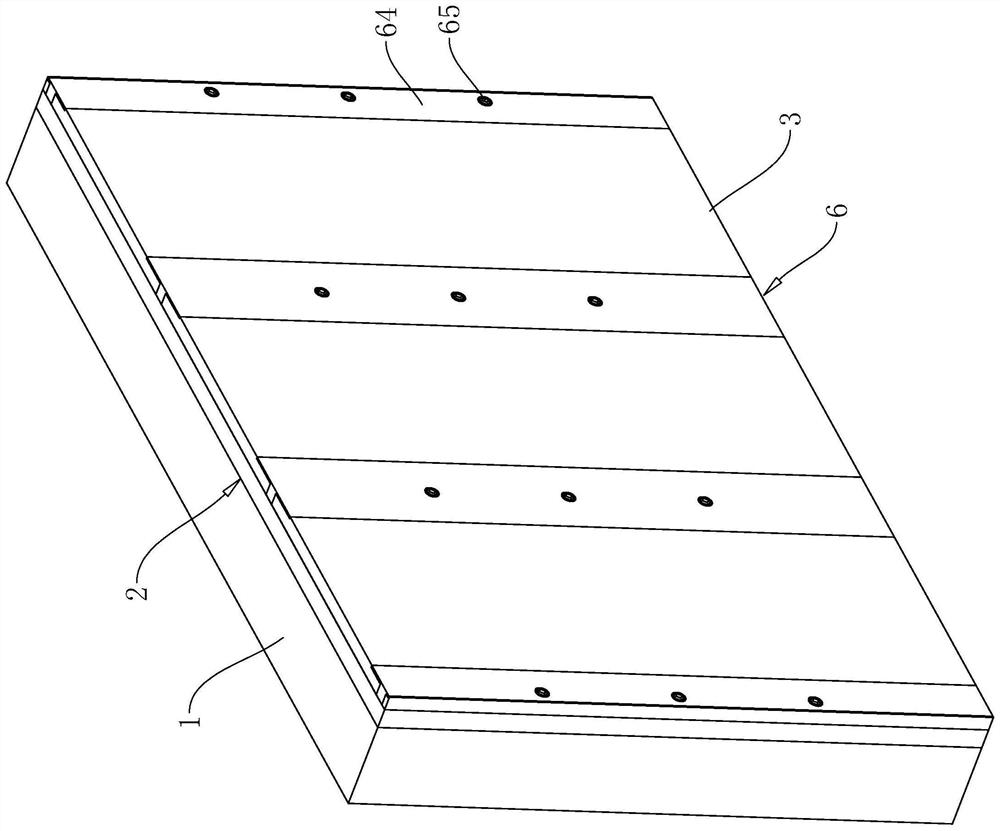

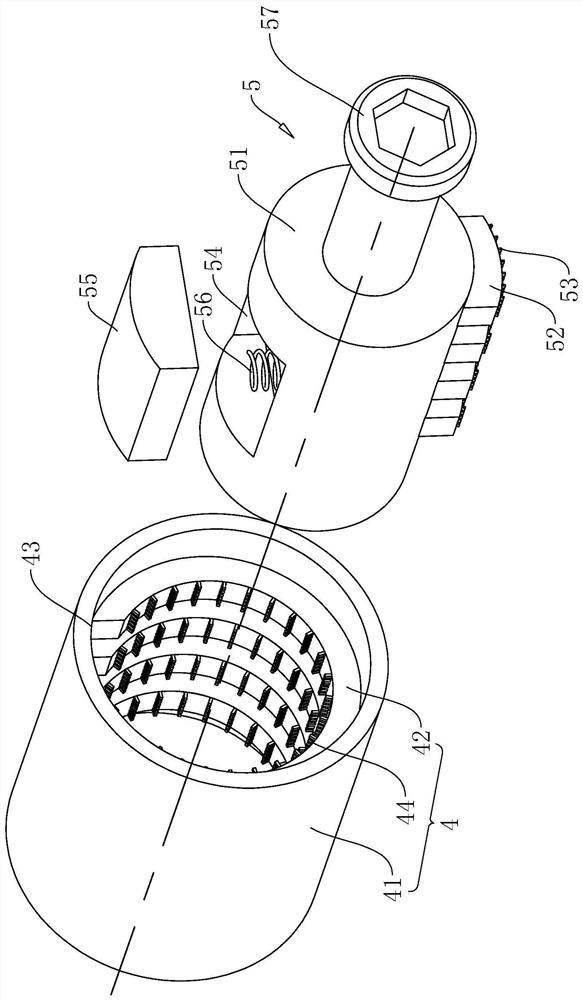

[0043] The embodiment of the present application discloses a prefabricated decorative wall that is convenient for dry construction. refer to figure 1 and figure 2 , a prefabricated decorative wall that is convenient for dry construction includes a wall 1, a keel frame 2 and a decorative wall panel 3 arranged in sequence. The wall 1 can be a prefabricated concrete wall 1 or existing concrete on the construction site. Body of wall 1, adopts prefabricated body of wall 1 in this embodiment. The keel frame 2 adopts a steel structure frame, and the keel frame 2 includes a plurality of criss-crossing horizontal bars 21 and vertical bars 22, the horizontal bars 21 and the vertical bars 22 are welded, and the horizontal bars 21 and the vertical bars 22 are located in the same plane. The cross bar 21 is connected with the first mounting part 5, and the wall body 1 is provided with the emb...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap