A multi-slit bush diameter variable device with threaded sleeve and its application method

A technology of slotted bushing and threaded sleeve, applied in the direction of threaded fasteners, nuts, connecting components, etc., can solve the problems affecting the cold extrusion strengthening process of holes, etc., to increase service life, reduce wear, and achieve multiple effect used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

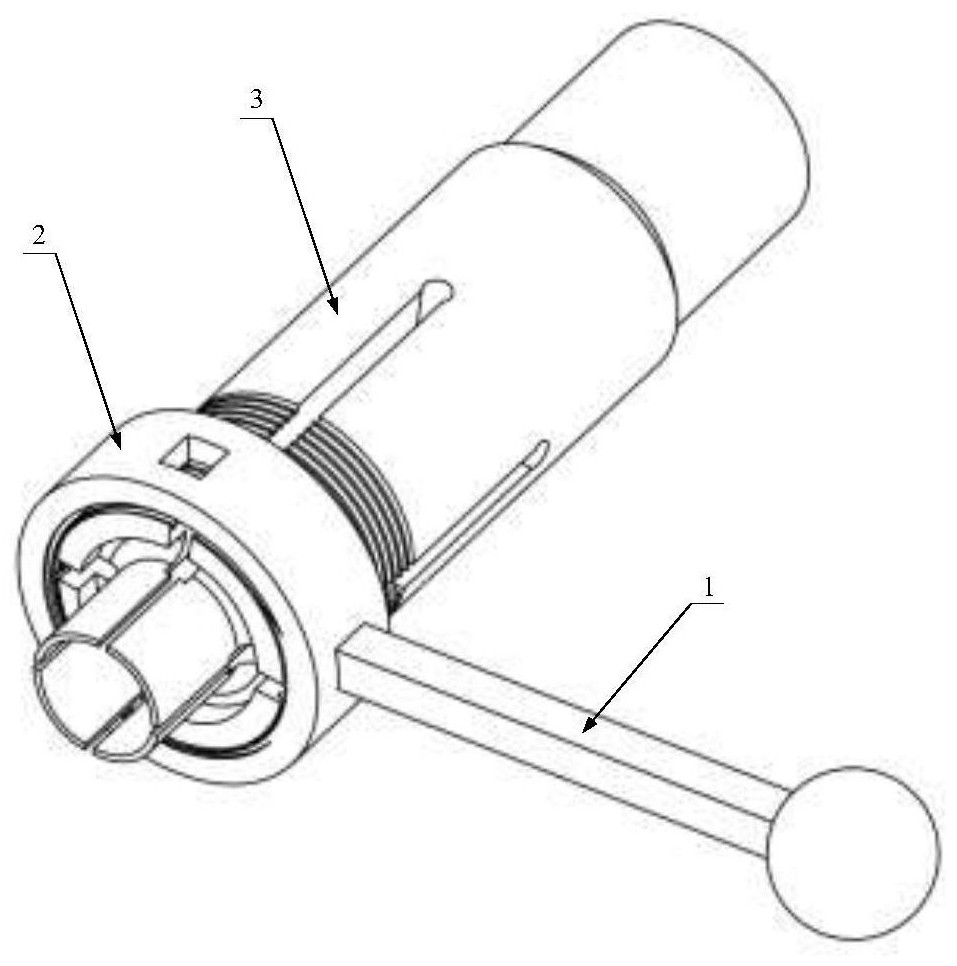

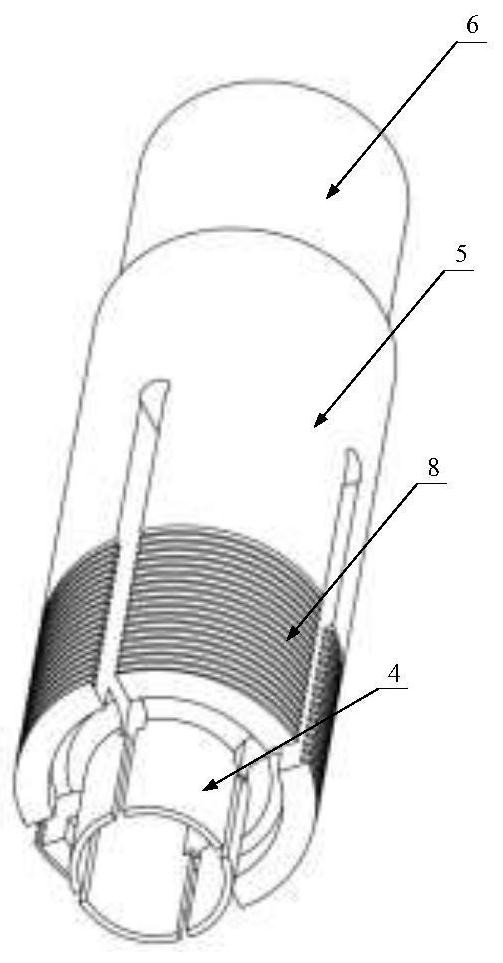

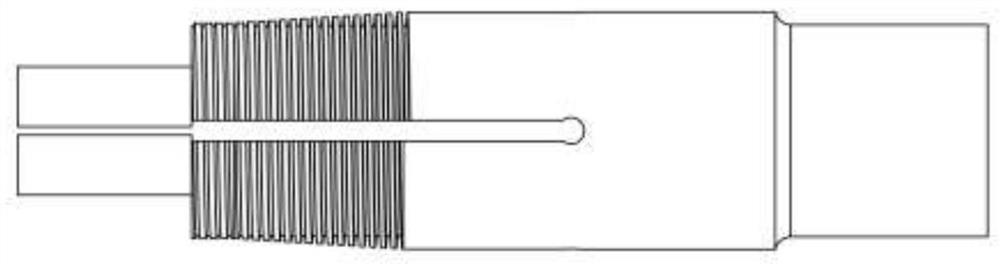

[0028] refer to figure 1 As shown, a multi-slit bush diameter variable device with a threaded sleeve and its use method include a rotary handle 1; a threaded sleeve 2; a multi-slit bush 3, wherein the rotary handle 1 is installed on the threaded sleeve 2, The threaded sleeve with the rotary handle is mounted on the middle part 5 of the multi-slit bush, and the middle part 5 of the multi-slit bush has a taper angle and has threads.

[0029] Turn the rotary handle 1, and the threaded sleeve 2 gradually moves from the middle part 5 of the multi-slit bushing to the tail part 6 of the bushing. During the process, the width of the slit on the multi-slit bushing 3 begins to narrow gradually, causing the front end 4 of the multi-slit bushing to The diameter decreases; turn the rotary handle 1 counterclockwise, the threaded sleeve 2 gradually moves from the middle part 5 of the multi-slit bushing to the front end 4 of the bushing, and the width of the slit on the multi-slit bushing 3 r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com