Modular crucible device for silicon carbide crystal growth and growth method thereof

A technology of crystal growth and silicon carbide, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., which can solve the problems that are not conducive to the preparation of high-quality single crystals, environmental changes, and the speed of process optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

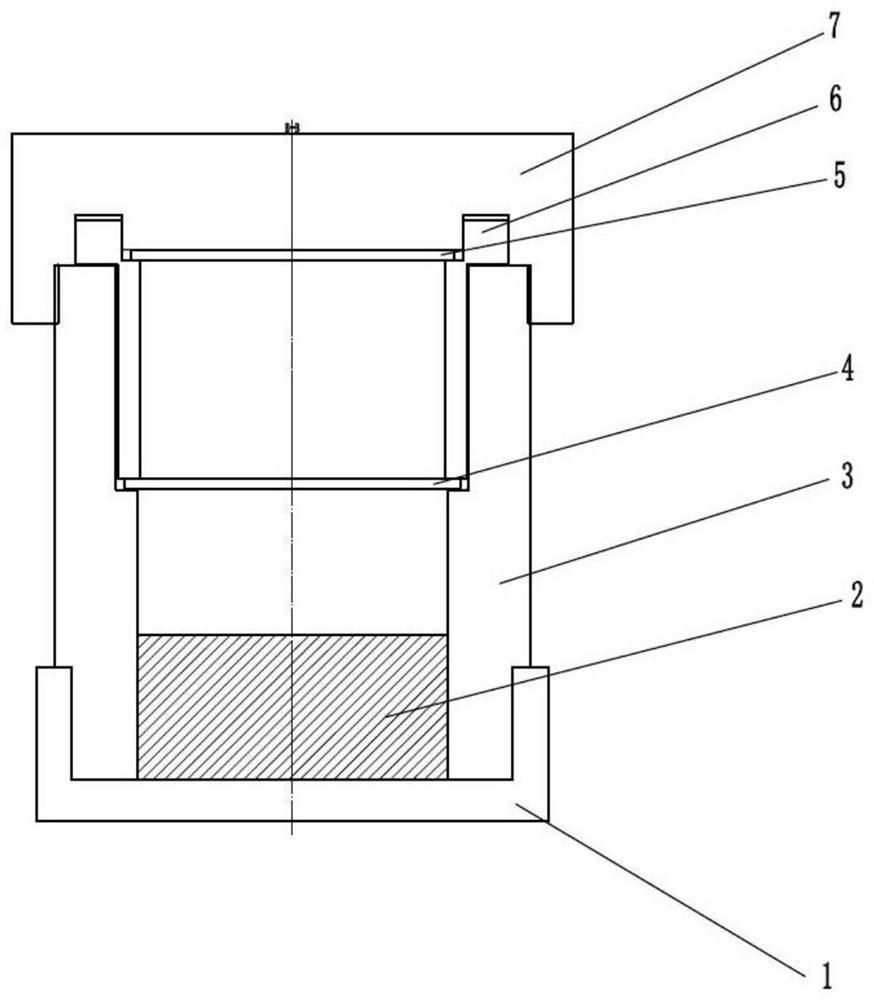

[0023] A modular crucible device for growing silicon carbide crystals, the described modular crucible device for growing silicon carbide crystals includes a crucible bottom 1, the crucible bottom is connected to a crucible body 3, and the crucible body The upper end of the crucible is provided with a crucible support 6, the upper layer of the crucible support is placed with a seed crystal 5, the lower layer of the crucible support is placed with a silicon carbide polycrystalline block 4, the bottom of the crucible body is placed with a silicon carbide powder 2, and the crucible cover 7 is connected to the crucible. Body cover.

[0024] A modular crucible device for silicon carbide crystal growth described in this embodiment, the crucible bottom and the crucible body are connected by bolts, the crucible body and the crucible support are connected by bolts, The crucible cover and the crucible body are connected by bolts.

[0025] In the modularized crucible device for silicon c...

specific Embodiment approach 2

[0032] According to the first embodiment, a silicon carbide crystal growth method of a modular crucible device for silicon carbide crystal growth includes the following steps:

[0033] Step 1. Assemble a modular crucible device for silicon carbide crystal growth. The crucible bottom and crucible body of a modular crucible device for silicon carbide crystal growth are tightly connected by graphite bolts, and then the silicon carbide powder is loaded into the described modular crucible device for silicon carbide crystal growth, then the crucible body and the crucible support are tightly connected by graphite bolts, and then the silicon carbide polycrystalline block is placed on the lower layer of the crucible support, and the The seed crystal is placed on the upper layer of the crucible support, and then the crucible cover and the crucible body are tightly connected by graphite bolts;

[0034] Step 2. Put a modular crucible device assembled in step 1 for the growth of silicon ca...

specific Embodiment approach 3

[0037] A modular crucible device for growing silicon carbide crystals, the described modular crucible device for growing silicon carbide crystals includes a crucible bottom 1, the crucible bottom is connected to a crucible body 3, and the crucible body The upper end of the crucible is provided with a crucible support 6, the upper layer of the crucible support is placed with a seed crystal 5, the lower layer of the crucible support is placed with a silicon carbide polycrystalline block 4, the bottom of the crucible body is placed with a silicon carbide powder 2, and the crucible cover 7 is connected to the crucible. Body cover.

[0038] A modular crucible device for silicon carbide crystal growth described in this embodiment, the crucible bottom and the crucible body are connected by bolts, the crucible body and the crucible support are connected by bolts, The crucible cover and the crucible body are connected by bolts.

[0039] In the modularized crucible device for silicon c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com