Method for obtaining working clearance of bearing through combination of test and numerical calculation

A numerical calculation and combination technology, applied in CAD numerical modeling, design optimization/simulation, electrical digital data processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to make the technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

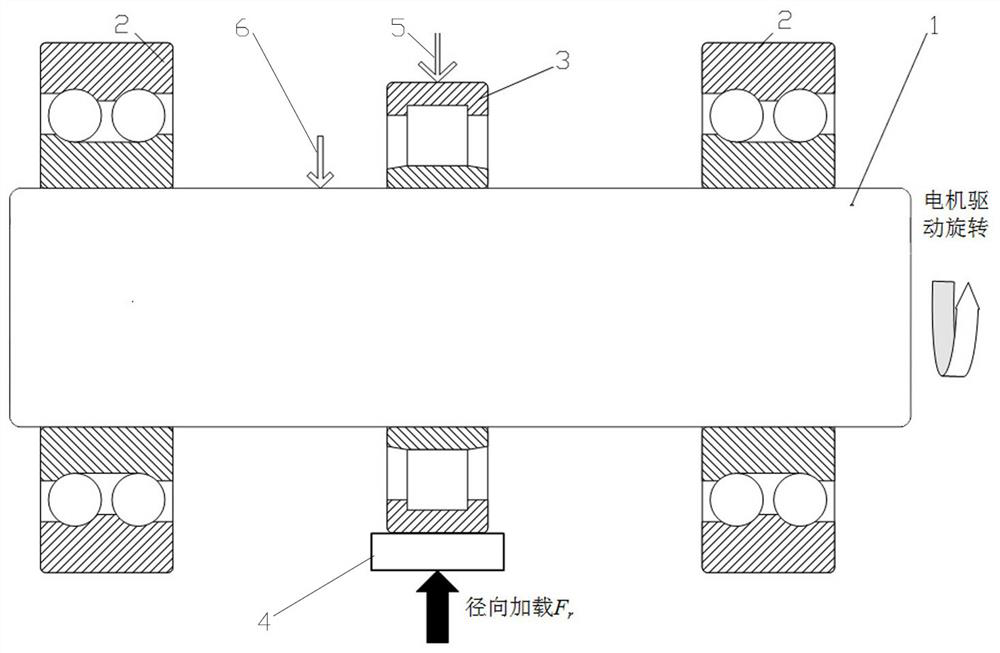

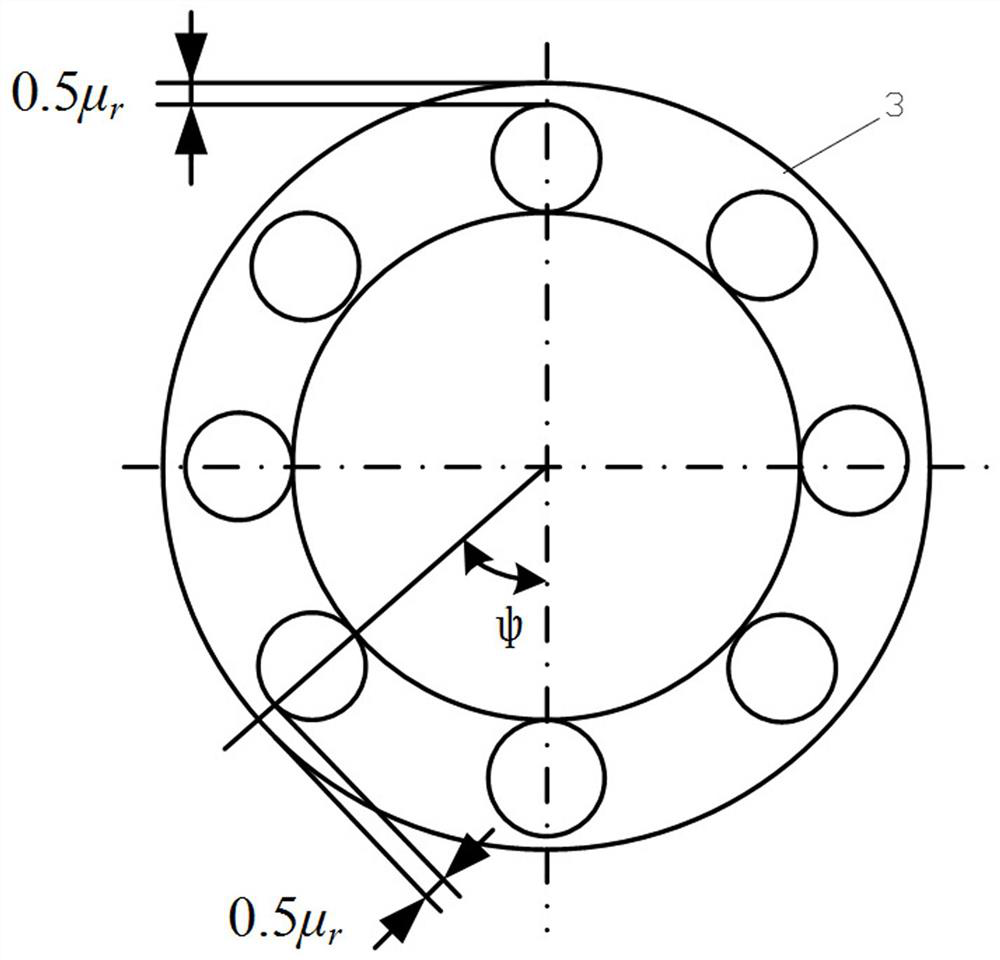

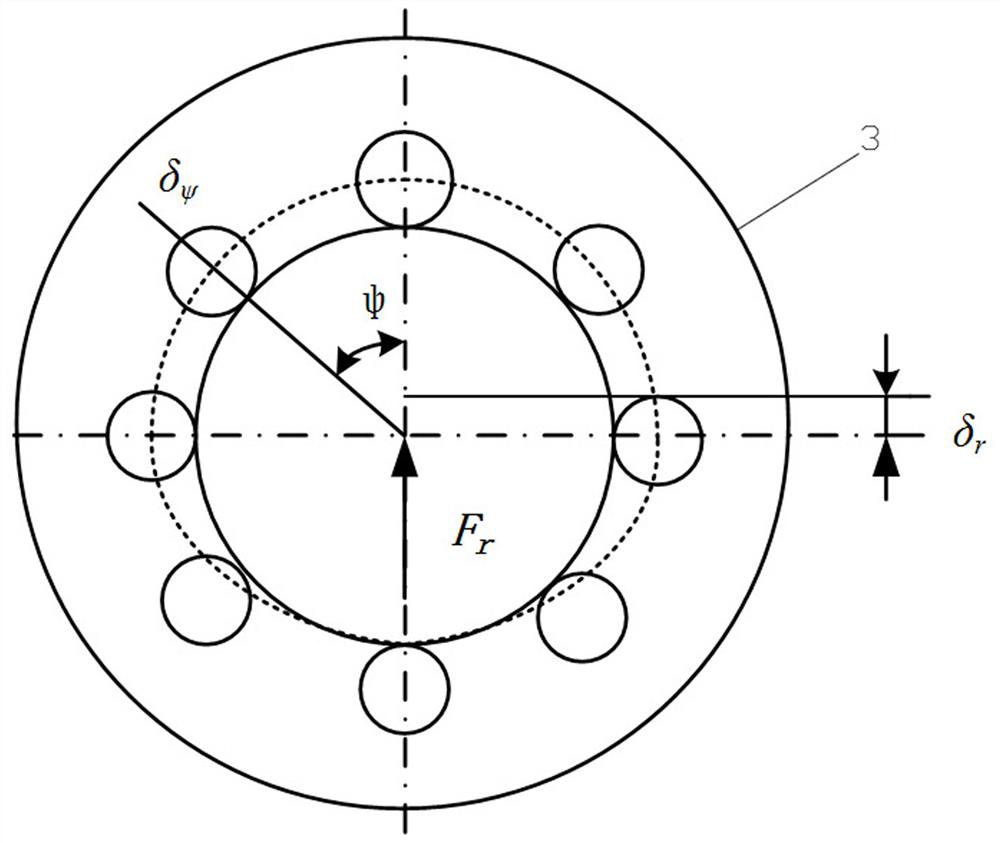

[0053] A method for obtaining the working clearance of a bearing by combining experiments and numerical calculations, including the following steps: (1) First, obtain the radial relative deformation of the bearing △ through the bearing test and measurement device r ; (2) Establish a bearing mechanical model considering the working clearance under bearing load; (3) Obtain the relative deformation δ of the inner and outer rings of the bearing under different working clearances through numerical calculation r ; (4), when calculating the amount of deformation δ r Equal to the test relative deformation △ r , the working clearance obtained at this time is the actual working clearance of the bearing.

[0054] The test and measurement device includes a support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com