A Clamp Control Circuit Suitable for Switching Power Chips

A switching power supply chip, control circuit technology, applied in control/regulation systems, electrical components, regulating electrical variables, etc., can solve problems affecting safety and reliability, large overshoot, etc., to achieve complete safety functions and good dynamic response. , the effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

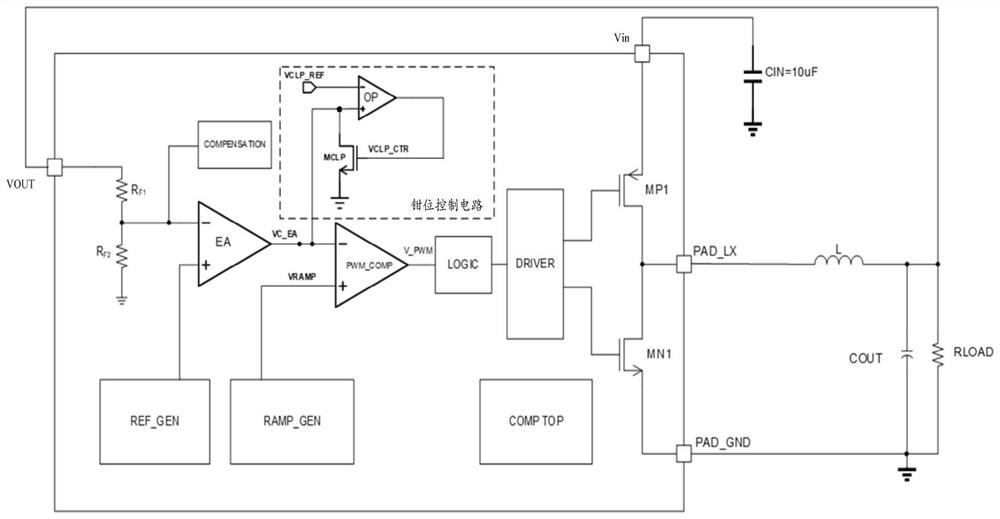

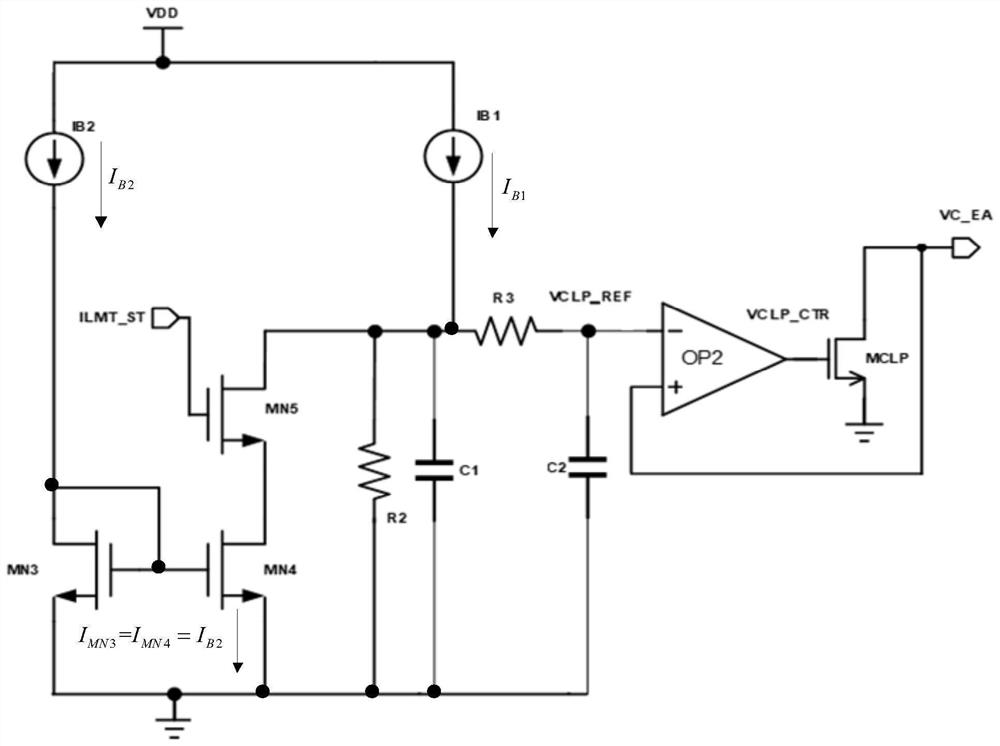

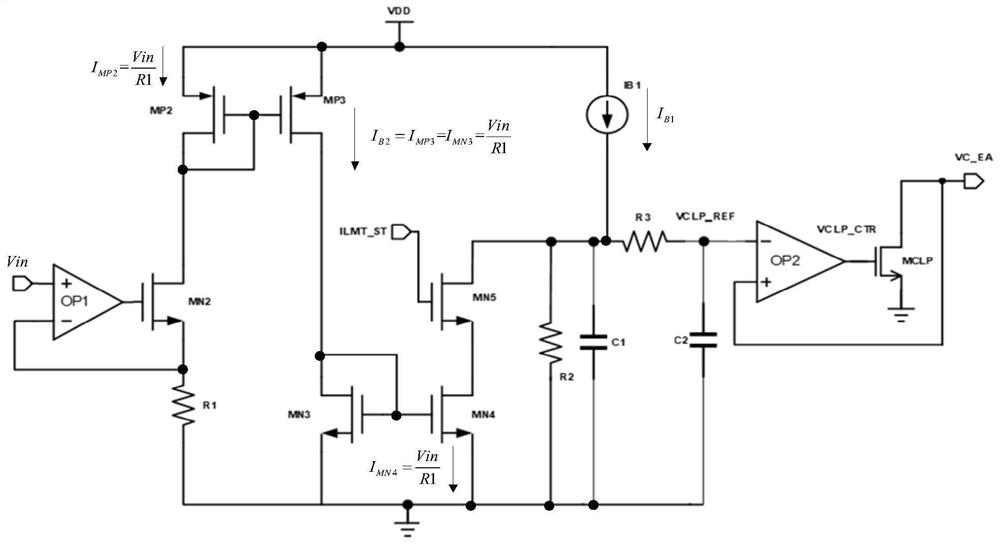

[0028] This application discloses a clamp control circuit suitable for switching power supply chips, please refer to figure 2 , the circuit structure of the switching power supply chip can refer to figure 1 , that is, in the switching power supply chip, the error amplifier EA generates the modulation signal VC_EA to the pulse modulation comparator PWM_COMP according to the output signal OUT of the switching power supply chip and the output reference voltage REF, and the pulse modulation comparator PWM_COMP generates according to the modulation signal VC_EA and the ramp voltage RAMP The square wave signal V_PWM controls and drives the upper tube MP1 and the lower tube MN1 through the driving module, and converts the battery input signal Vin into the corresponding output signal VOUT. The clamp control circuit is connected to the common termin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com