System and method for controlling the isodiametric growth of crystal

A technology of equal diameter growth and control system, applied in crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problem that it is difficult to further improve the diameter control accuracy, the crystal diameter growth is limited, and it is difficult to achieve the production purpose of crystal equal diameter growth, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

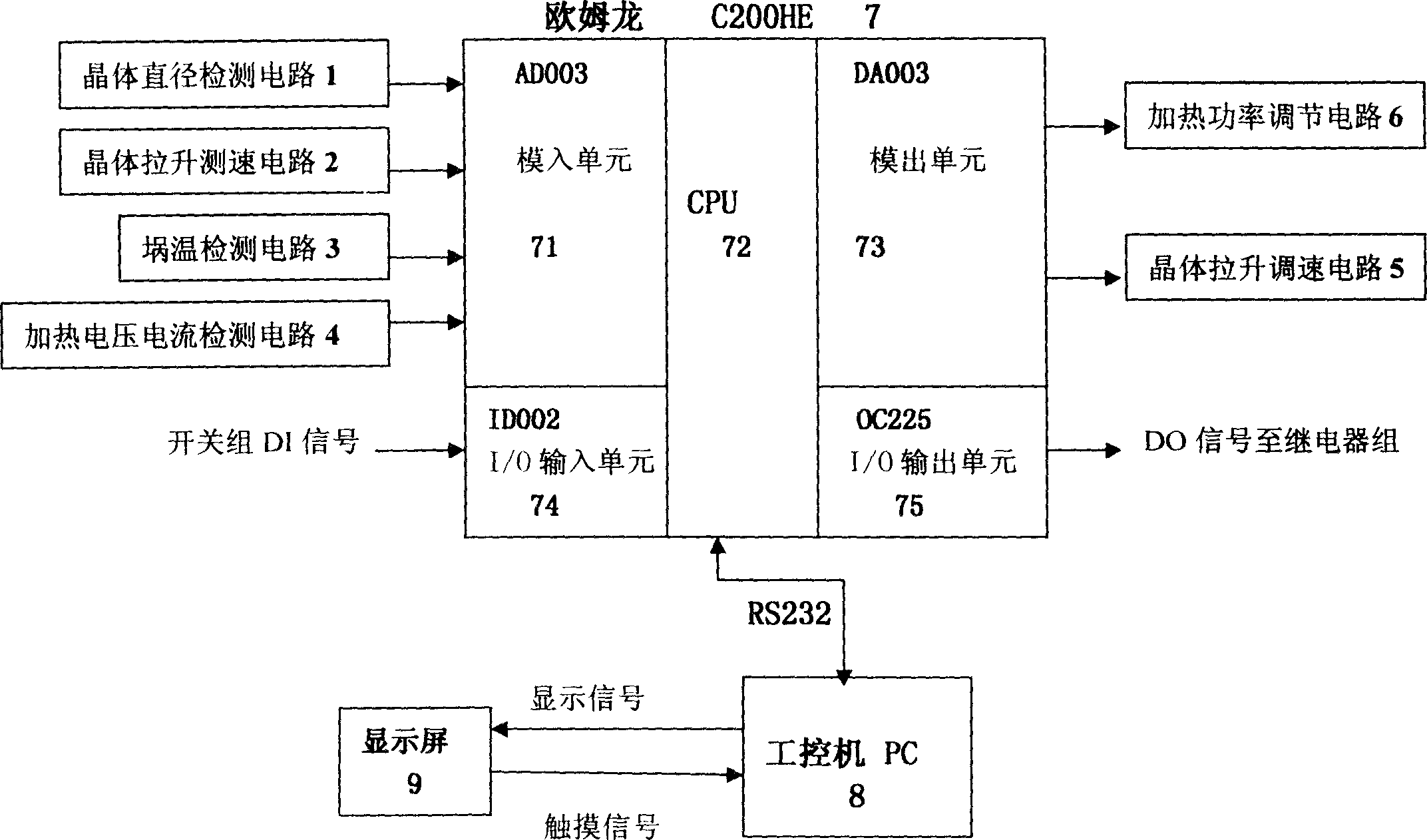

[0046] see figure 1 , the control system of crystal equal-diameter growth in this embodiment has a crystal growth furnace, a crystal diameter detection circuit 1, a crystal pull-up speed measurement circuit 2, a crucible temperature detection circuit 3, a heating voltage and current detection circuit 4, and a crystal pull-up speed regulation circuit 5. Heating power adjustment circuit 6, controller 7, industrial computer 8 and display screen 9.

[0047] The crystal diameter detection signal output end of the crystal diameter detection circuit 1 is electrically connected to the crystal diameter detection signal input end of the controller 7, and the crystal pull-up speed measurement signal output end of the crystal pull-up speed measurement circuit 2 is connected to the crystal pull-up speed measurement signal of the controller 7. The input end is electrically connected, the output end of the crucible temperature detection signal of the crucible temperature detection circuit 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com