Multifunctional poultry breeding cage for animal husbandry

A multi-functional, breeding cage technology, applied in the field of poultry breeding cages, can solve the problems of heavy labor and unable to complete cleaning in time, and achieve the effect of avoiding infection and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

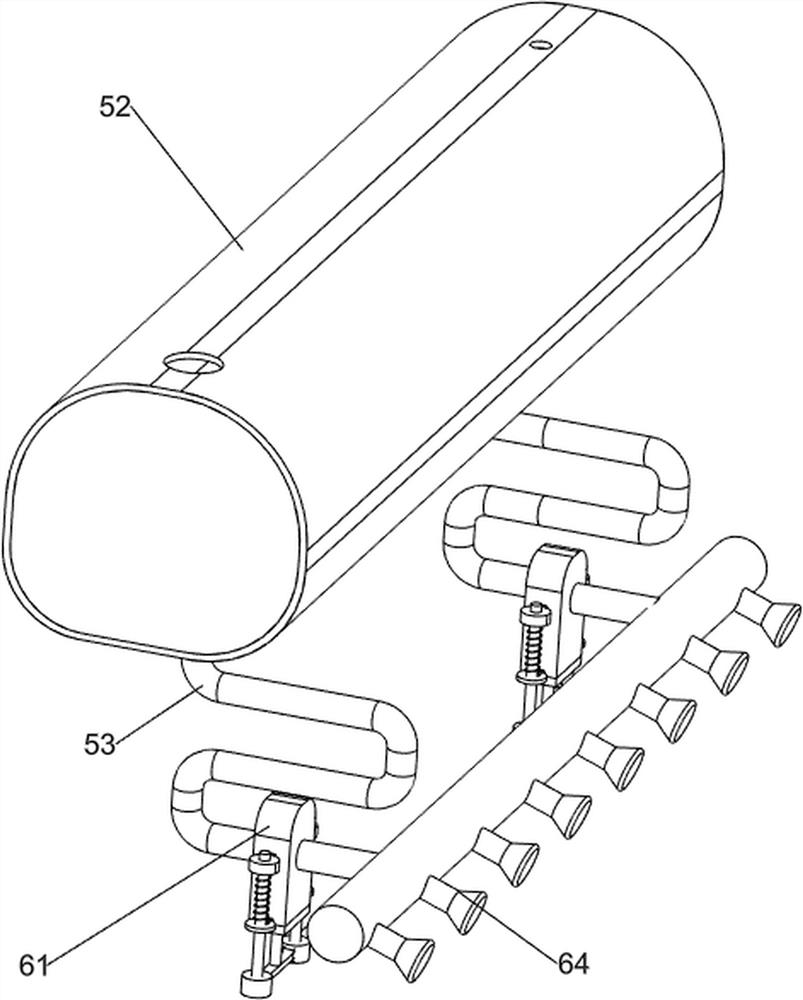

[0060] A kind of multifunctional poultry breeding cage for animal husbandry, such as Figure 1-4 As shown, it includes a base 1, a support frame 2, a breeding cage 3, an opening and closing plate 4, a water storage mechanism 5, and a cleaning mechanism 6. There are 4 support frames 2 on the top of the base 1, and a breeding cage is arranged between the upper parts of the support frames 2. 3. The front side of the breeding cage 3 is rotatably connected with an opening and closing plate 4, and the right front side of the breeding cage 3 is rotatably connected with a clamping rod, which clamps the opening and closing plate 4. The left side of the base 1 is provided with a water storage mechanism 5, and the water storage mechanism 5 parts are provided with cleaning mechanism 6.

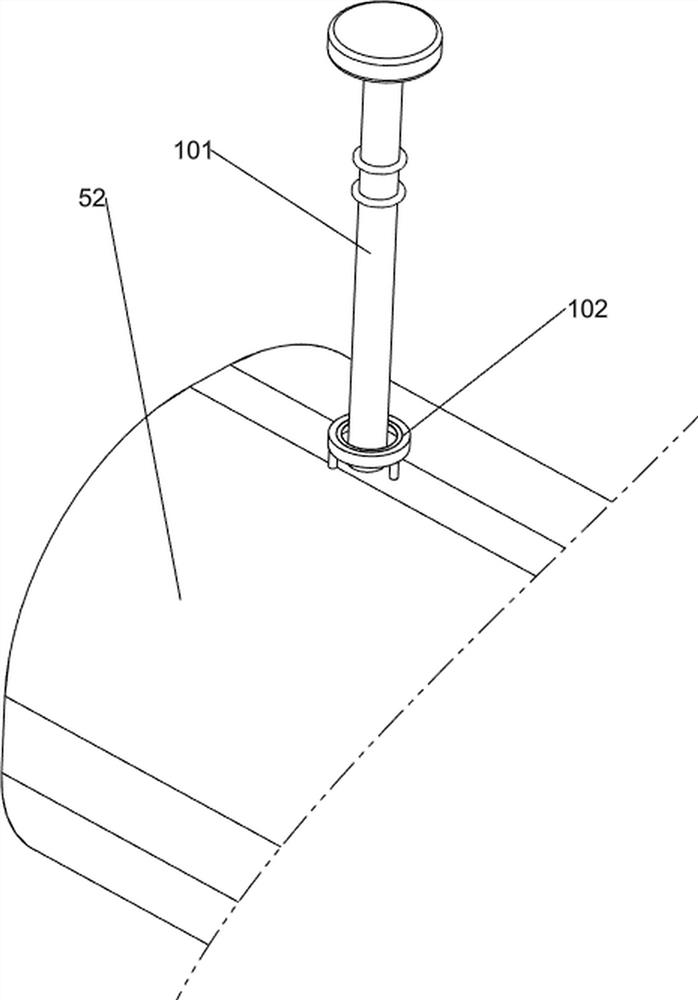

[0061] The water storage mechanism 5 includes a first support 51, a water storage tank 52 and a water pipe 53. The left side of the base 1 is provided with a first support 51, and the top of the first sup...

Embodiment 2

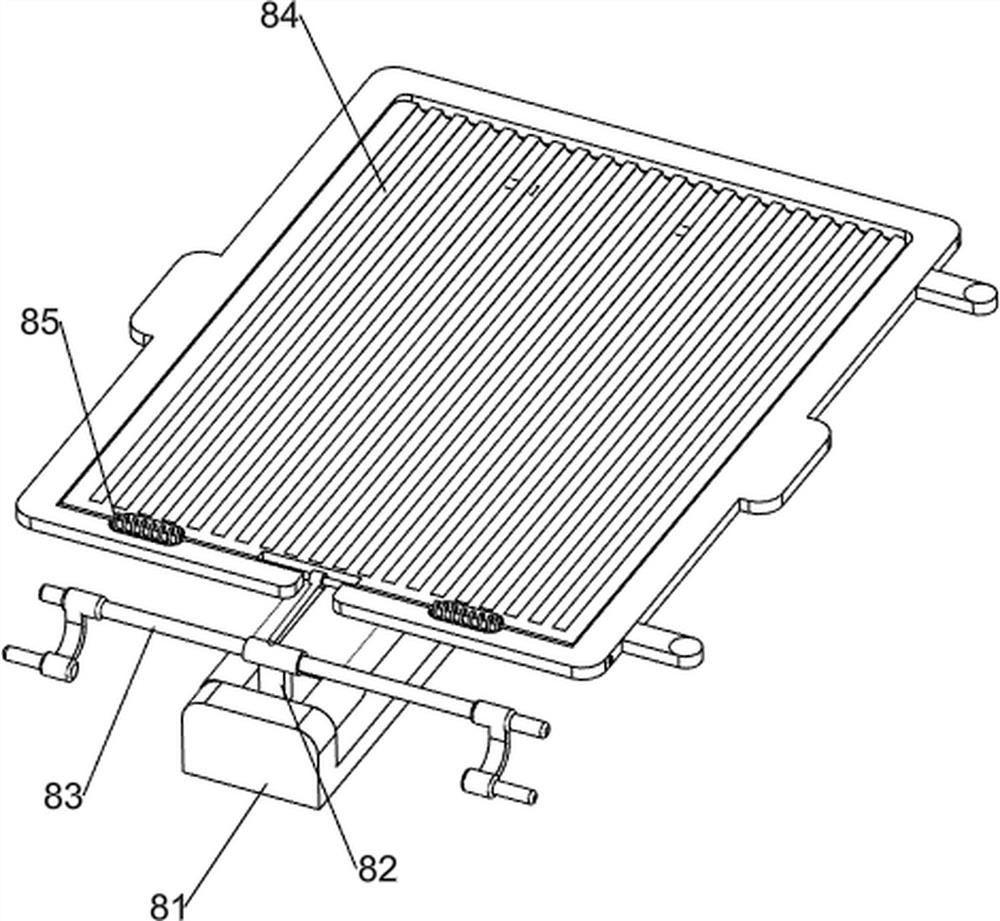

[0065] On the basis of Example 1, such as Figure 5-10As shown, also includes descending mechanism 7, and descending mechanism 7 includes telescoping rod 71, fixed frame 72, support plate 73, second support 74, first rotating rod 75, connecting rod 76, rotating rod 77, the 3rd rotating rod 78 and projection 79, base 1 top is provided with 4 telescopic rods 71, and telescopic rod 71 interiors are all provided with spring, is provided with fixed frame 72 between the telescopic rods 71 of horizontal same side, is provided with support between the telescopic rods 71 tops Plate 73, support plate 73 top front and rear both sides are all provided with round table, support plate 73 tops contact with rearing cage 3 bottoms, base 1 left side is symmetrically provided with second support 74, and the second support 74 tops are all rotatably connected with first Rotating bar 75, fixed mount 72 upper left sides are all slidably connected with connecting rod 76, the left side of connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com