Intelligent dust falling device based on plant building

A dust suppression device and intelligent technology, which can be used in construction, use of liquid separators, road cleaning, etc., can solve problems such as unsatisfactory dust suppression effects, and achieve the effect of avoiding excessive waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

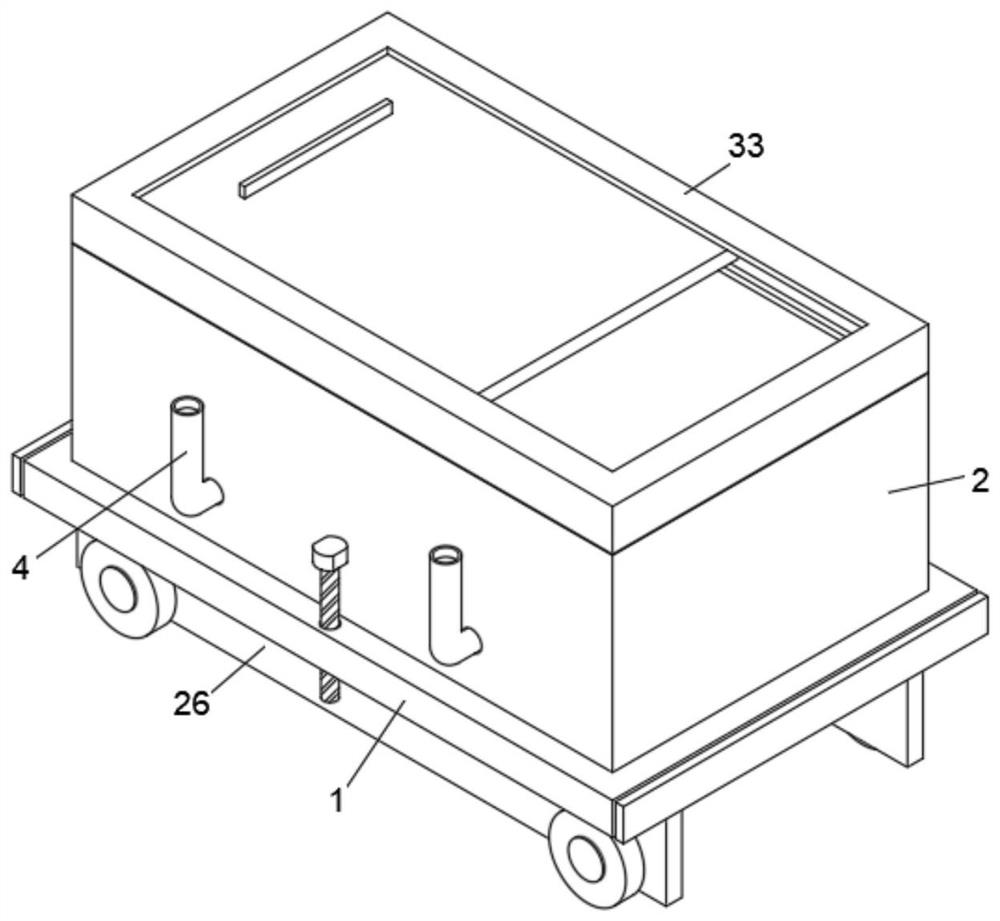

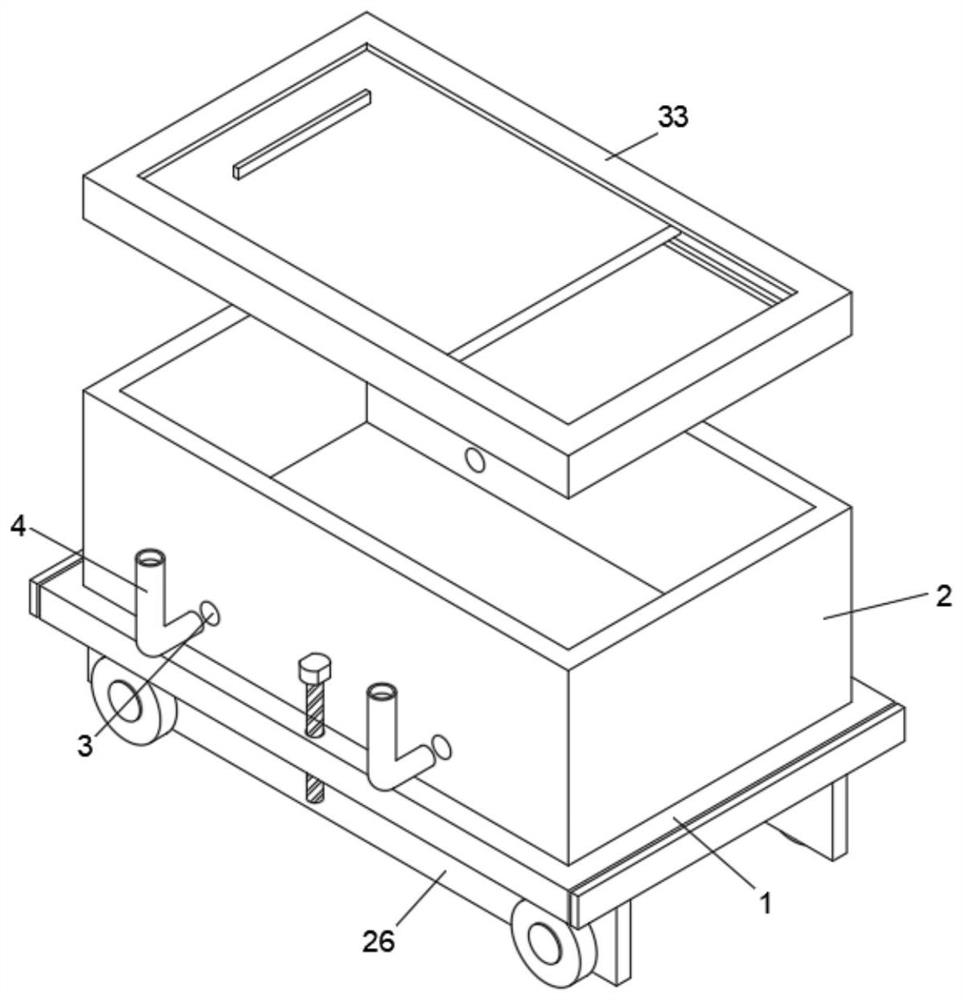

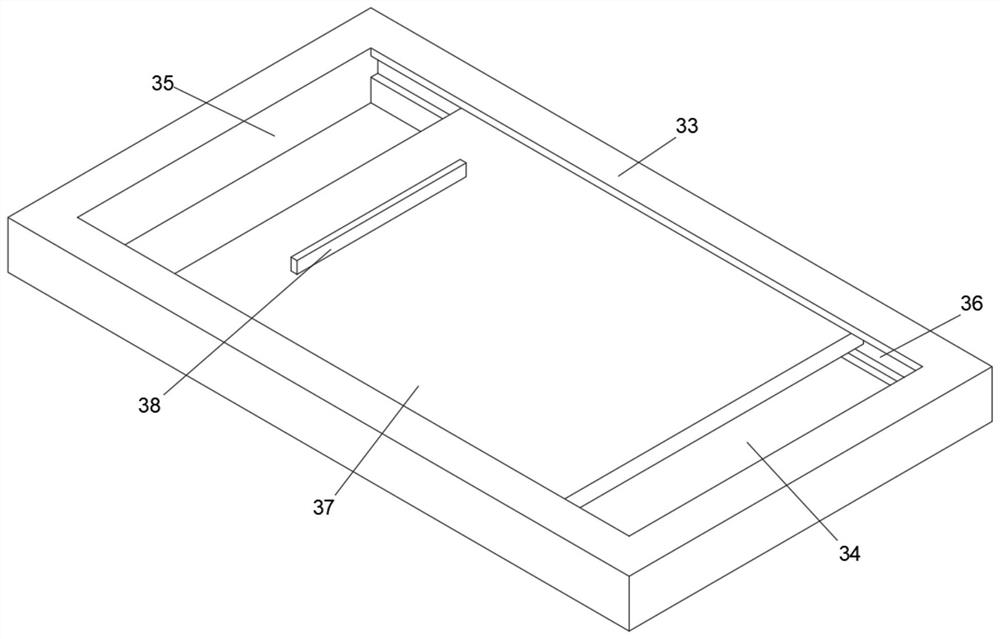

[0036] In a typical implementation of the present application, such as Figure 1-9 As shown, an intelligent dust suppression device based on plant construction includes a base plate 1, the base plate 1 is a rectangular structure, the top surface of the base plate 1 is fixedly equipped with a housing 2, the housing 2 is a rectangular hollow structure, and the top surface of the housing 2 is open. There are two side holes 3 on both sides of the shell 2. The side holes 3 are circular through holes. The inside of the side holes 3 is fixed with a sprinkler pipe 4. The sprinkler pipe 4 is an L-shaped pipe. A small water pump and an atomizer are installed inside. The small water pump and atomizer are prior art and will not be described here. There is a feeding mechanism on the surface. By setting the sprinkling pipe 4, the staff injects the dust-reducing water source into the interior of the casing 2 through the top hole 35, and then starts the small water pump and atomizer inside th...

Embodiment 2

[0041] In order to overcome the deficiencies in the prior art, the present invention also provides an intelligent dust reduction method based on plant construction, the specific steps are as follows:

[0042] S1: first start the small water pump and atomizer inside the sprinkling pipe 4, and the dust in the air outside the device is dedusted by the sprinkling pipe 4, and the first step is completed;

[0043] S2: pull the pull block 23, so that the pull block 23 leaves the inside of the side groove 22, so that the water source inside the shell 2 enters the inside of the bottom pipe 8, and completes the second step;

[0044] S3: The water source hits the rotating plate 21 due to gravity, and the rotating plate 21 drives the rotating block 20 to rotate, disperses the falling water column inside the casing 2, and wets the dust on the ground, completing the third step.

[0045] When in use, by setting the sprinkling pipe 4, the staff injects the dust-reducing water source into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com