Automatic riveting and tinning device for generator stator

A generator stator and riveting piece technology, applied in tin feeding devices, other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of low efficiency, product quality relying on manual control, wasting time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

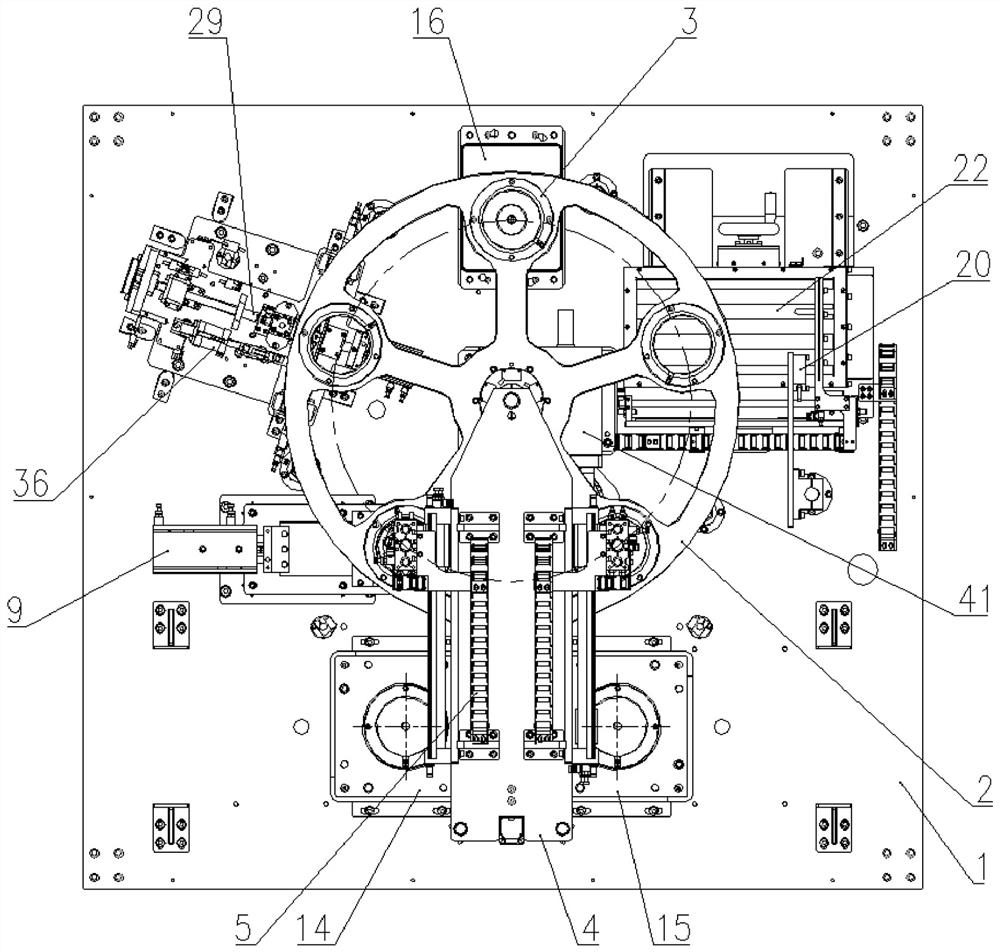

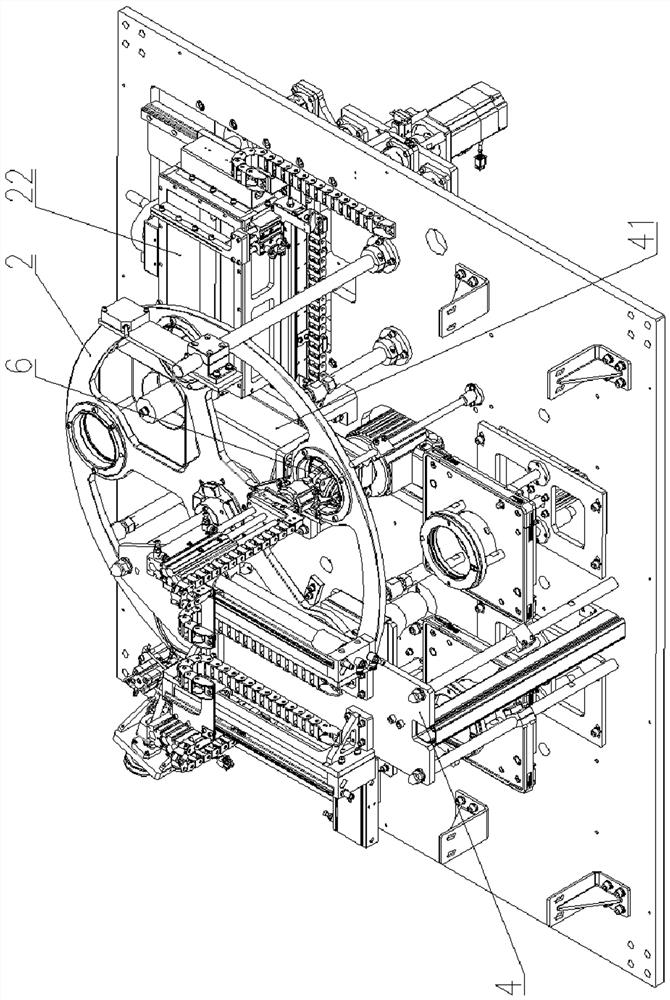

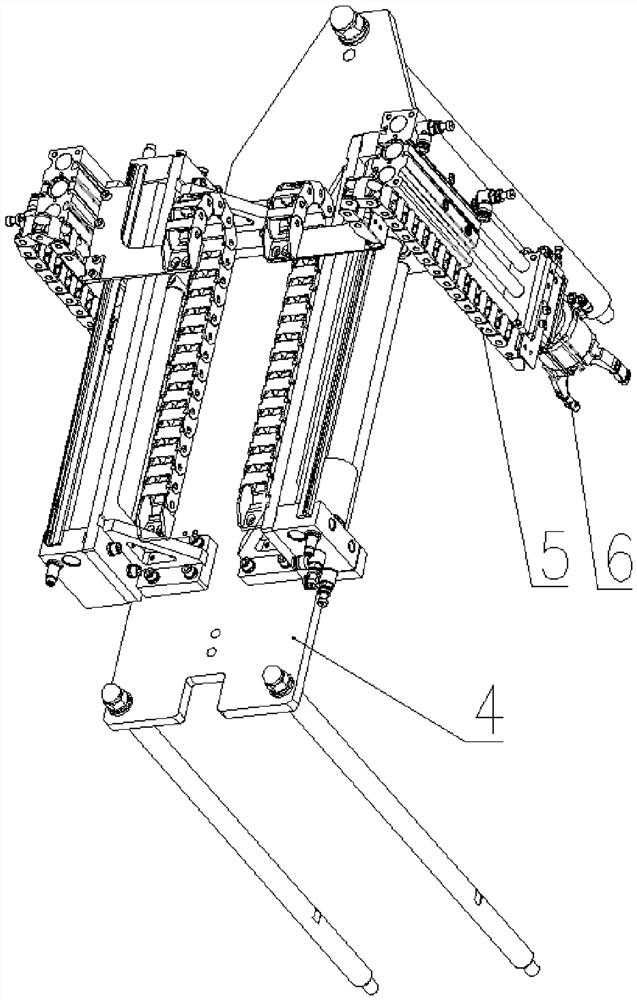

[0025] An embodiment of the tinning device for automatic riveting of the generator stator of the present invention:

[0026] see Figure 1-Figure 12, a generator stator automatic riveting tinning device, including a base plate 1, the base plate 1 is equipped with a product on and off line grabbing device, a thread trimming device, a riveting device, a flux soaking device, a tinning device and a cycle turntable 2. The above-mentioned product on and off-line grabbing device, thread trimming device, riveting device, flux soaking device, and tinning device surround the circulation turntable 2 and arrange them on the bottom plate 1 according to the order of the stations. The circulation turntable 2 is equipped with There are five stator seats 3, the five stator seats 3 are evenly distributed on the circumference and can be rotated to each station, the circulation turntable 2 is located below the product loading and unloading grabbing device, and is located above other station devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com