A wave glider cushioning structure

A buffer structure and glider technology, applied in special-purpose ships, ship construction, ship propulsion, etc., can solve the problems of changing the appearance performance of wave gliders, the difficulty of buffer design, etc., to extend the survivability of high sea conditions, prolong the service life, Damage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following is further described in detail through specific implementation methods:

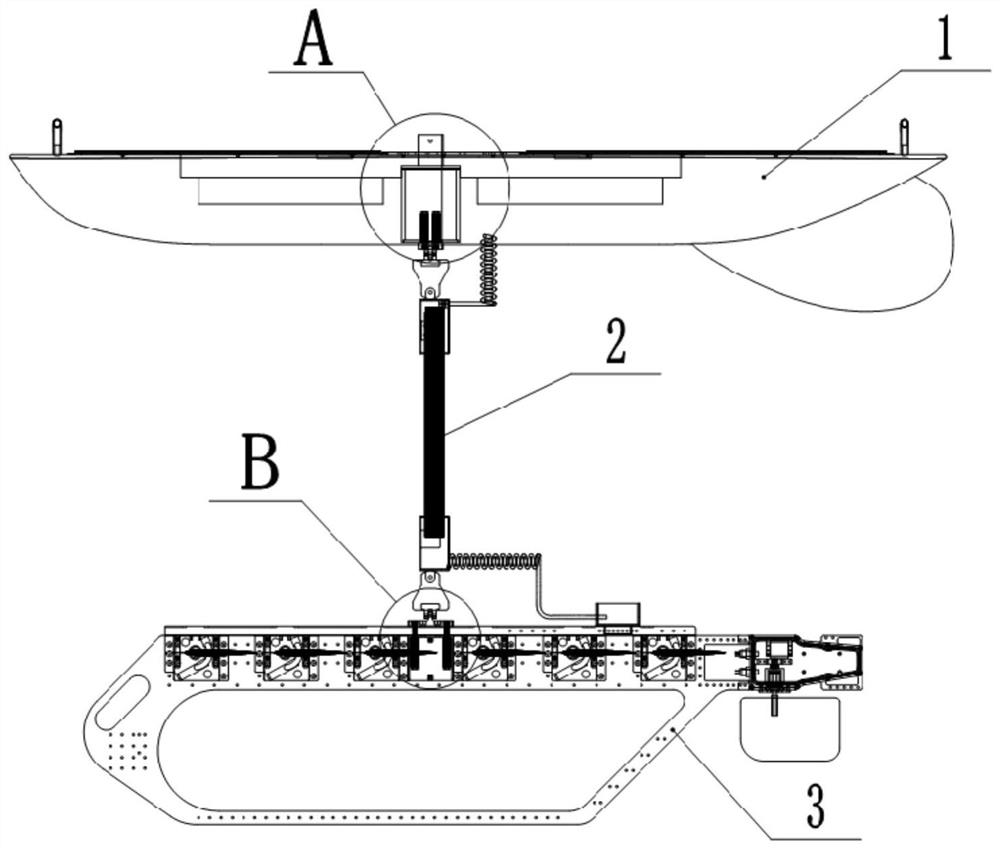

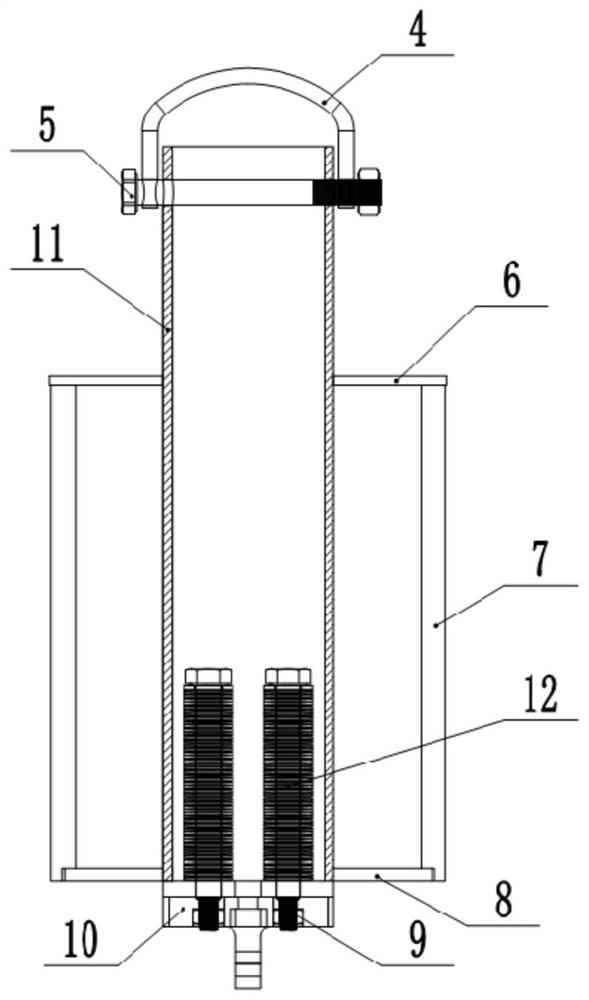

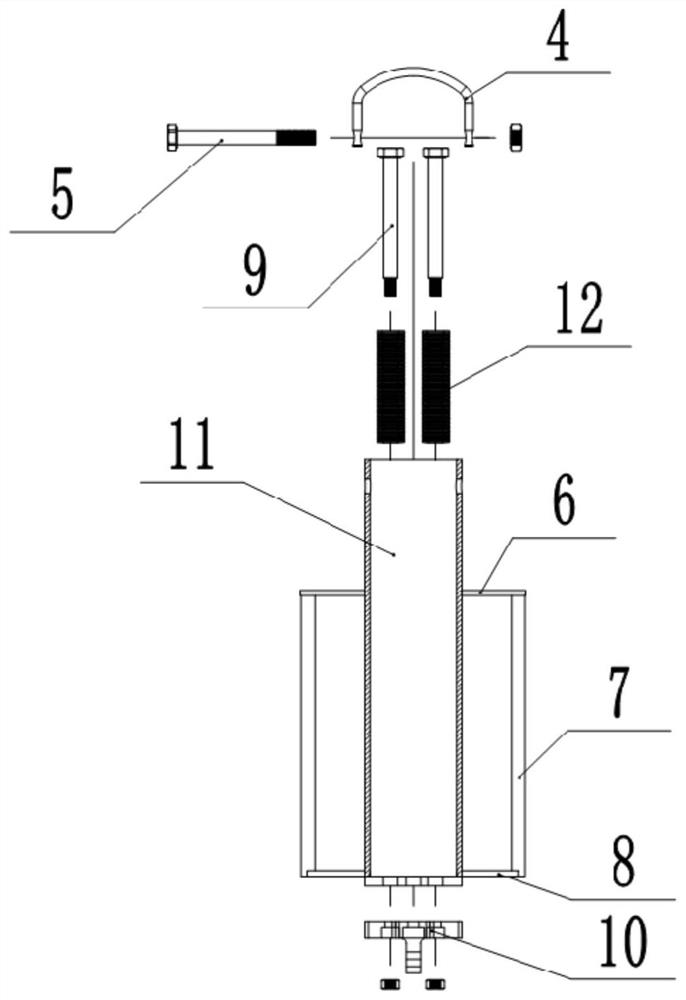

[0037] The reference signs in the drawings of the description include: surface hull 1, umbilical cable 2, underwater gliding thruster 3, lifting ring 4, upper bolt pair 5, ship deck support flange 6, auxiliary support column 7, ship bottom support flange 8. Upper guide rod 9, upper connector 10, main support column 11, upper disc spring group 12, lower connector 13, lower guide rod 14, lower disc spring group 15, fixed flange 16, screw hole 17, buffer box 18. Main beam 19, groove 20, connection hole 21.

[0038] The embodiment is basically as attached figure 1 Shown: a wave glider buffer structure, including a surface hull buffer unit and a propeller buffer unit, the wave glider includes a surface hull 1, an underwater glider propeller 3 and an umbilical cable 2, combined figure 2 and image 3 As shown, the surface hull buffer unit includes a main support column 11. In this embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com