A preparation method of high-strength bio-based composite fiber and composite fiber

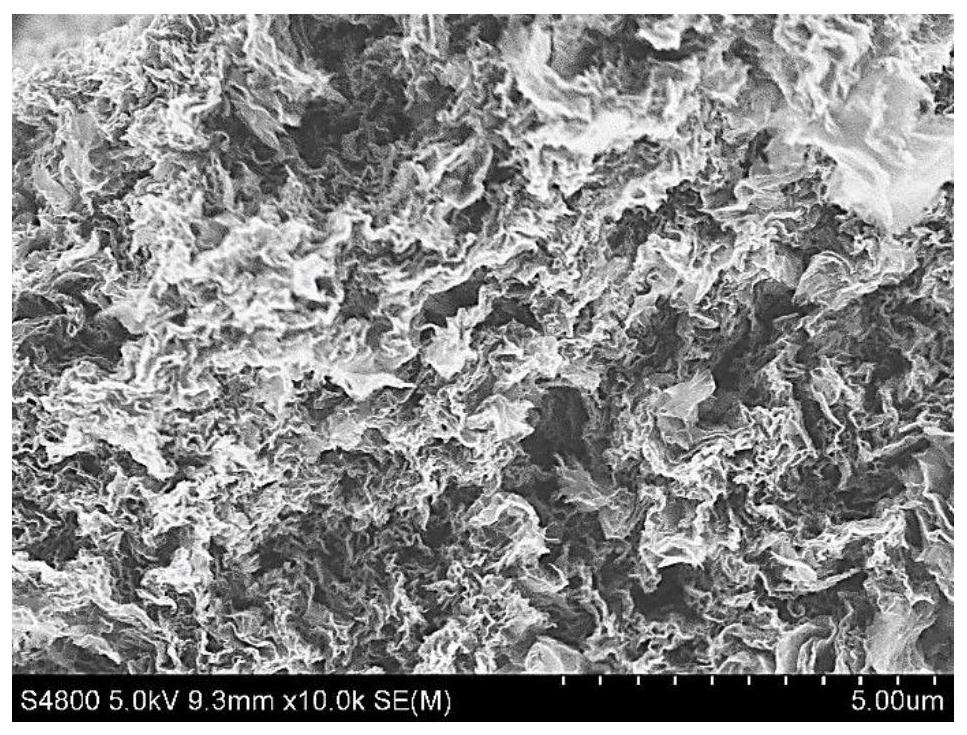

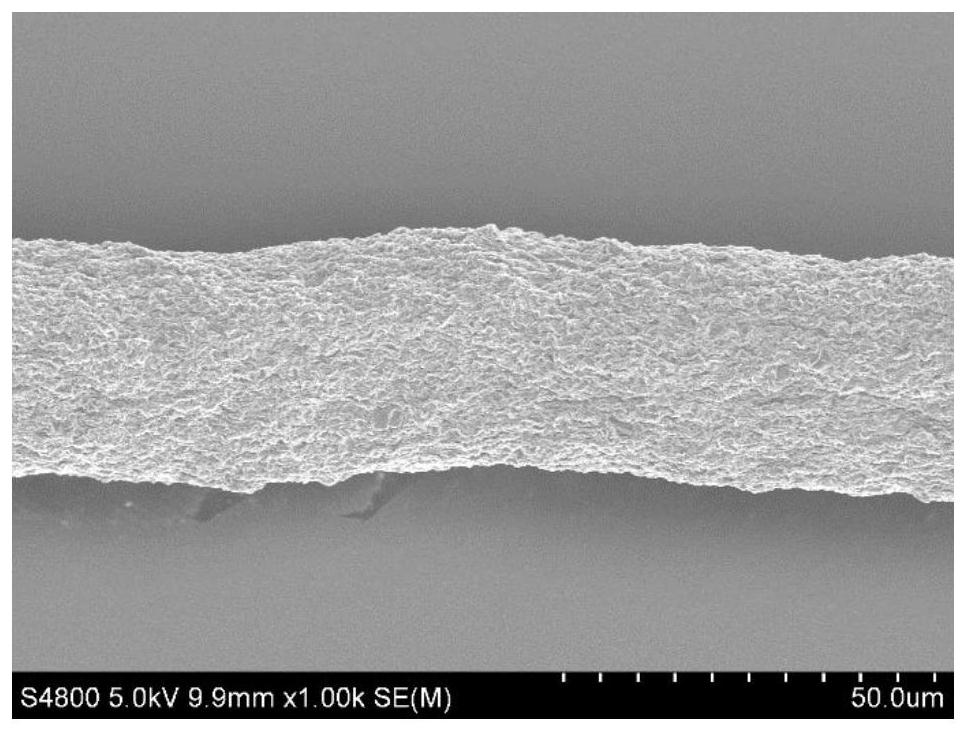

A composite fiber, bio-based technology, applied in the direction of fiber chemical characteristics, cellulose/protein conjugated rayon, wet spinning, etc., can solve the problem of low strength, irregular size and shape of graphene fibers, hindering graphene Fiber application and other issues, to achieve the effect of enhanced bonding, good electrical conductivity, and reduced stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

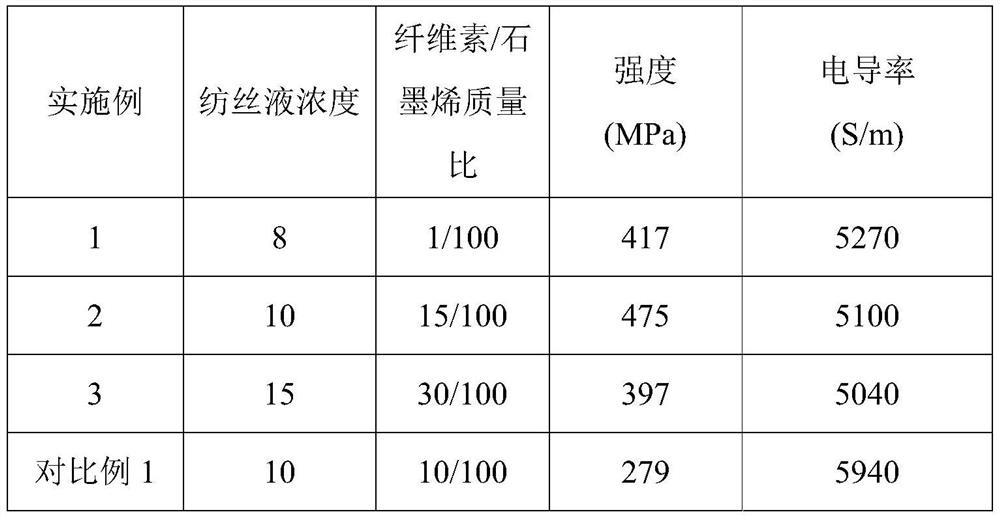

Embodiment 1

[0027] Embodiment 1: The preparation of high-strength bio-based composite fiber comprises the following steps:

[0028] (1) Preparation of graphene oxide solution: prepare 8 g / L graphene oxide (prepared by Hummers method) aqueous solution, add ammonia water to adjust pH to 5.

[0029] (2) Modification of graphene oxide: add KH550 accounting for 1% of the mass of graphene oxide to the graphene oxide solution, and stir at 25° C. for 8 hours to obtain a solution C containing modified graphene oxide.

[0030] (3) Modification of cellulose: 5 g of cotton linter fibers were mixed with 40 mL of 10% sodium hydroxide aqueous solution and 100 mL of absolute ethanol solution, and stirred and reacted at 40° C. for 4 h. Add 5g of sodium chloroacetate and stir the reaction at 70°C for 3h. After washing with absolute ethanol and drying, the modified cotton linter fibers were prepared into 8 g / L solution E with water as solvent.

[0031] (4) Preparation of spinning solution: Mix solution C ...

Embodiment 2

[0035] Embodiment 2: the preparation of high-strength bio-based composite fiber, comprising the following steps:

[0036] (1) Preparation of graphene oxide solution: prepare 10 g / L graphene oxide aqueous solution (prepared by Hummers method), add ammonia water to adjust pH to 8.

[0037] (2) Modification of graphene oxide: add KH550 accounting for 5% of the mass of graphene oxide to the graphene oxide solution, and stir at 25° C. for 5 h to obtain solution C containing modified graphene oxide.

[0038] (3) Modification of cellulose: 5 g of cotton linter fibers were mixed with 40 mL of 20% sodium hydroxide and 100 mL of absolute ethanol solution, and stirred and reacted at 50° C. for 2 h. Add 10g of sodium chloroacetate, and stir the reaction at 60°C for 4h. After washing with absolute ethanol and drying, the modified cotton linter fibers were prepared into a solution E of 10 g / L with water as a solvent.

[0039] (4) Preparation of spinning solution: Mix solution C and soluti...

Embodiment 3

[0043] Embodiment 3: the preparation of high-strength bio-based composite fiber, comprising the following steps:

[0044](1) Preparation of graphene oxide solution: prepare 15 g / L graphene oxide (prepared by Hummers method) aqueous solution. Aqueous ammonia was added to adjust the pH to 12.

[0045] (2) Modification of graphene oxide: add KH550 accounting for 10% of the mass of graphene oxide to the graphene oxide solution, stir at 25° C. for 4 hours, and obtain solution C.

[0046] (3) Modification of cellulose: 5 g of cotton linter fibers were mixed with 40 mL of 30% sodium hydroxide and 100 mL of absolute ethanol solution, and stirred and reacted at 40° C. for 1 h. Add 10g of sodium chloroacetate, and stir the reaction at 80°C for 2h. After washing with absolute ethanol and drying, the modified cotton linter fibers were prepared into a 15 g / L solution E with water as a solvent.

[0047] (4) Preparation of spinning solution: Mix solution C and solution E at a ratio of 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com