Manufacturing method of silencing element used in front of carbon tank electromagnetic valve

A sound-absorbing element and a technology of a manufacturing method, which are applied in the direction of valves, devices for absorbing fluid energy, engine components, valve devices, etc., can solve the problems of both rigidity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

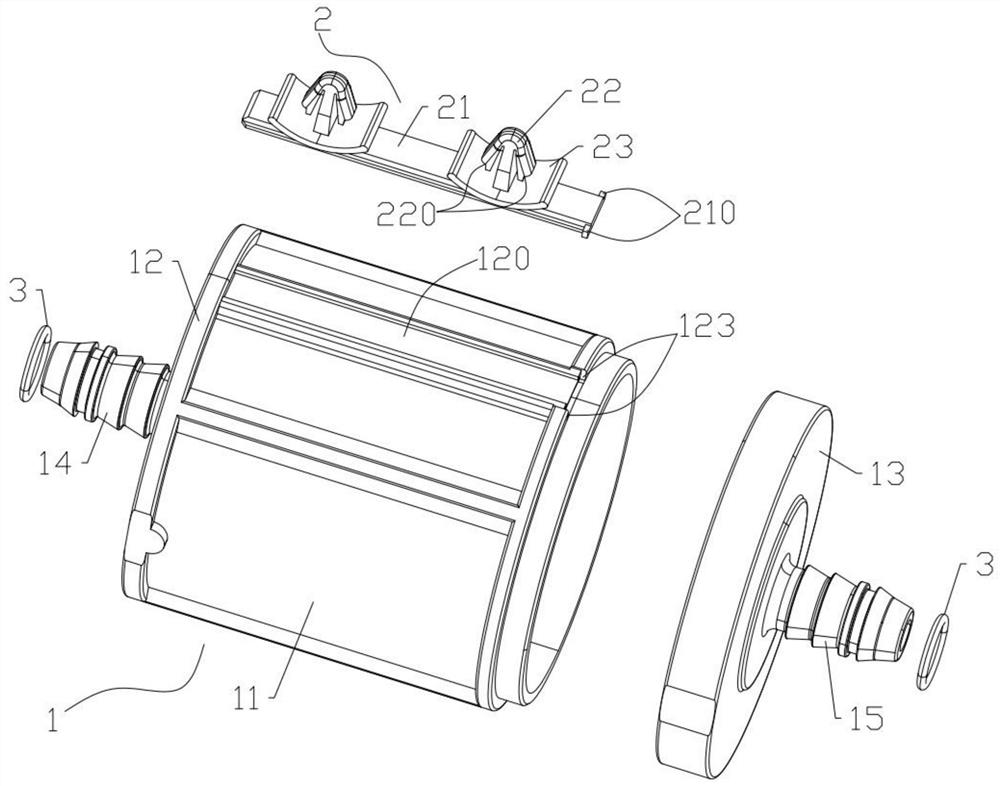

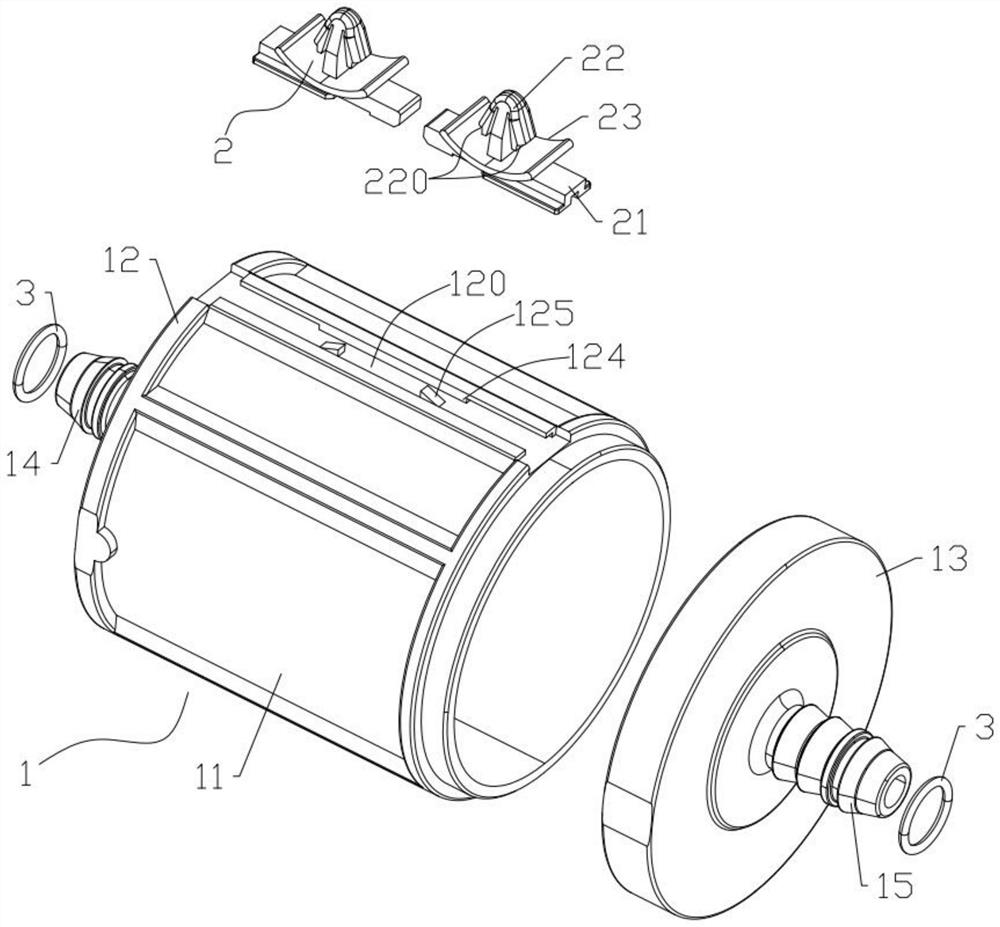

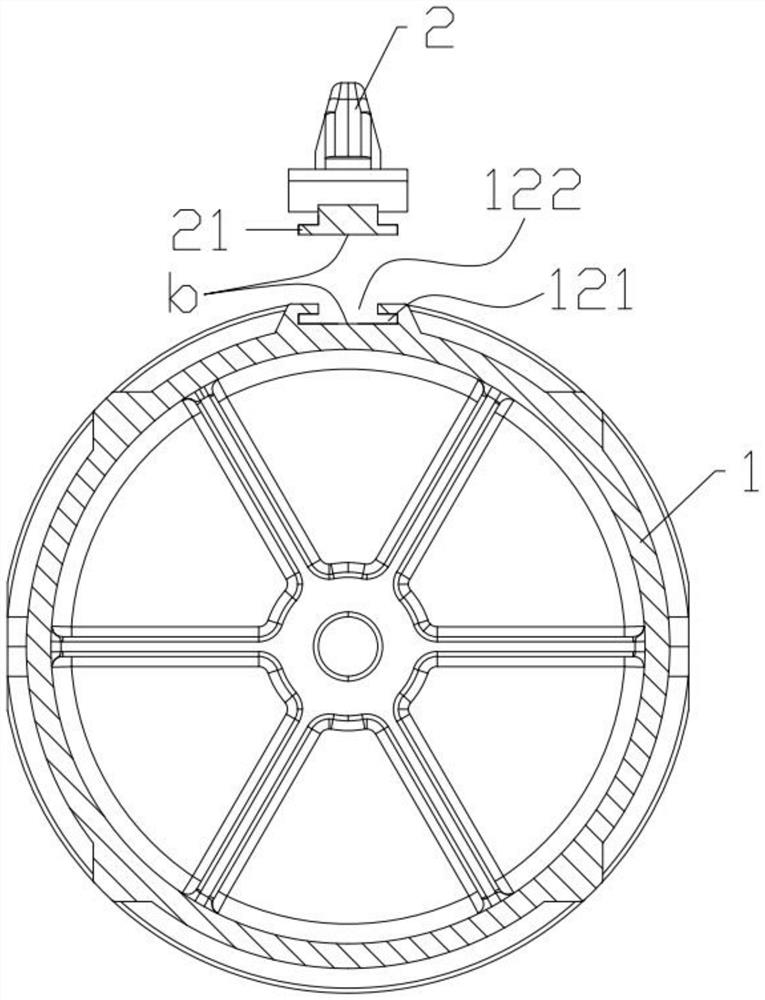

[0030] Such as figure 1 with 2 As shown, a muffler element used in front of the carbon canister solenoid valve includes a muffler body 1 and at least one fixing structure 2 arranged on the surface of the muffler body 1, and the fixing structure 2 is used for fixing the vehicle plate (sheet metal) fixing, and then the muffler body 1 is fixed on the vehicle fixing plate (sheet metal); the material rigidity of the muffler body 1 is greater than the material rigidity of the fixing structure 2, or / and, The material toughness of the fixing structure 2 is greater than that of the muffler body 1 .

[0031] The muffler element is made of different materials between its muffler body 1 and the fixed structure 2, and the muffler body 1 is made of a rigid material, so that the muffler body 1 has a higher impact strength to meet When it is connected and assemble...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com