Rubber diaphragm sealing performance detection device

A sealing detection and rubber diaphragm technology, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, and detecting the appearance of fluid at the leakage point, etc., can solve the problem of affecting the quality of rubber diaphragms, large accidents, and rubber diaphragms. Unable to make accurate detection and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

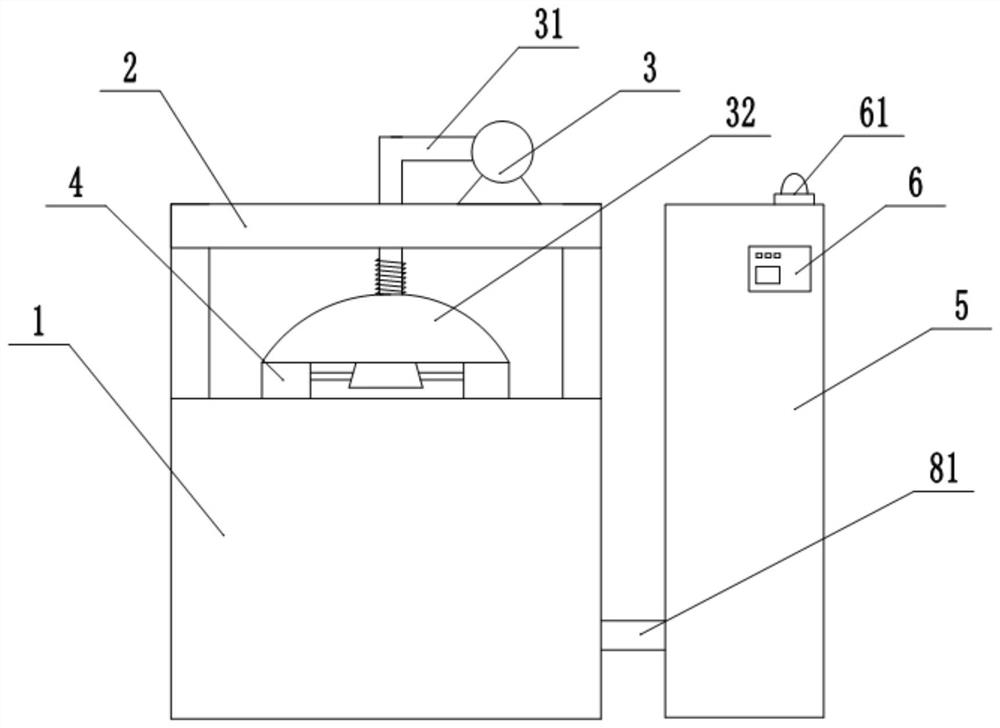

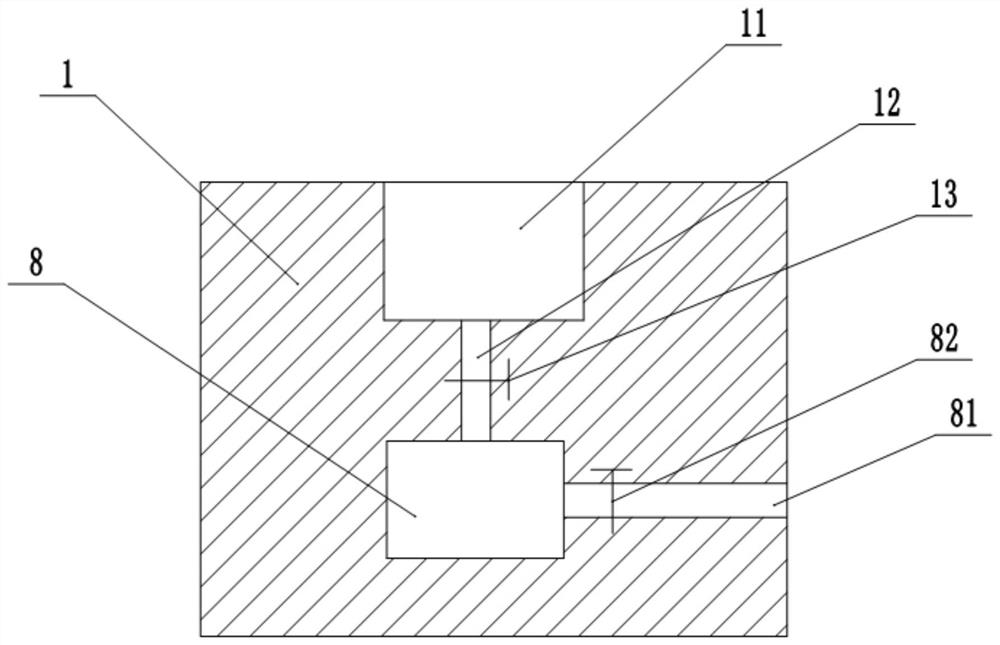

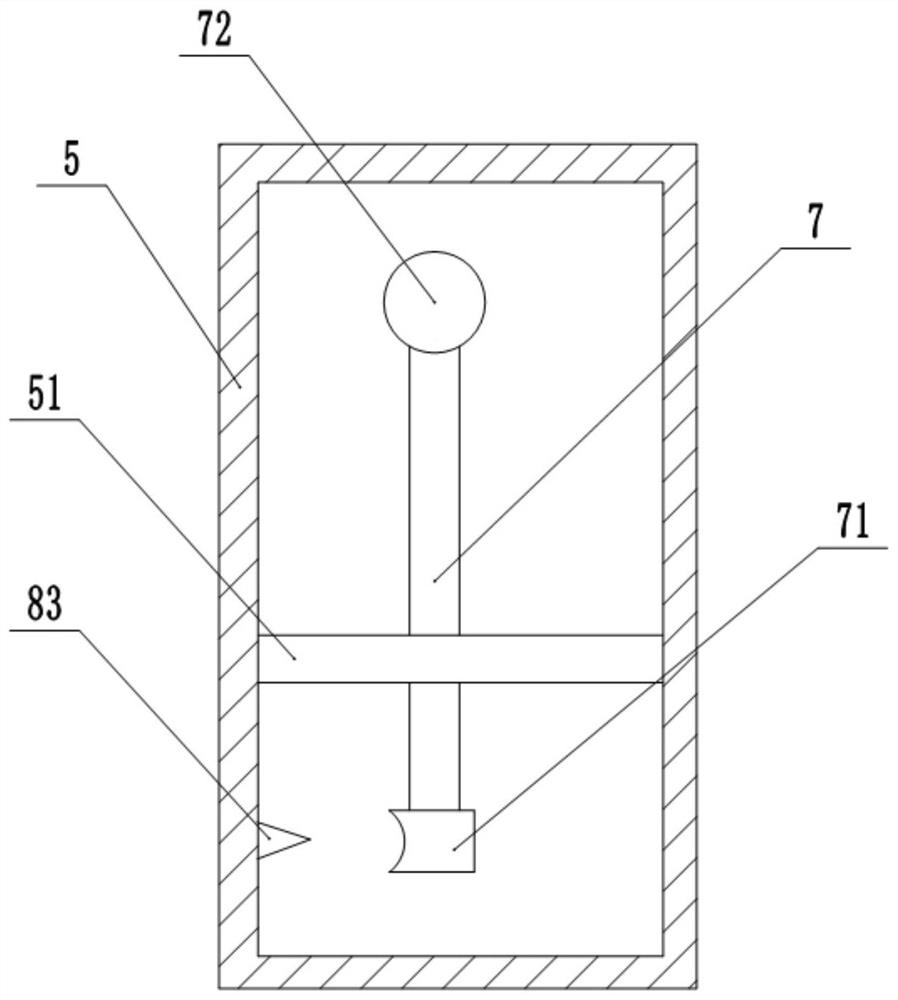

[0027] A rubber diaphragm leak detection device, such as figure 1 with 2 As shown, the console 1 and the detection box 5 are included, the console 1 is formed with an air guide chamber 11 and an air storage chamber 8, and a first air guide tube 12 is connected between the air guide chamber 11 and the air storage chamber 8, and the first A one-way valve 13 is installed on the air guiding tube 12 , the top of the air guiding chamber 11 is an open structure, and the rubber diaphragm can cover the open end of the air guiding chamber 11 to close the air guiding chamber 11 .

[0028] Such as figure 1 with 5 As shown, an annular pressing block 4 is installed on the console 1, and when the rubber diaphragm covers the open end of the air guiding chamber 11, the annular pressing block 4 can be attached to the edge of the rubber diaphragm. The ring-shaped pressing block 4 is assembled by several arc-shaped blocks 41, and each adjacent side of two arc-shaped blocks 41 is assembled with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com