Piezoelectric micromotor based on multistage flexible amplification and driving method thereof

A micro-motor and amplifying mechanism technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the problem of limited application range, complex driver program, and multi-level structure and other issues to achieve the effect of increasing the scope of work and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following examples can be more fully understood by the invention, but will not limit the invention in any way.

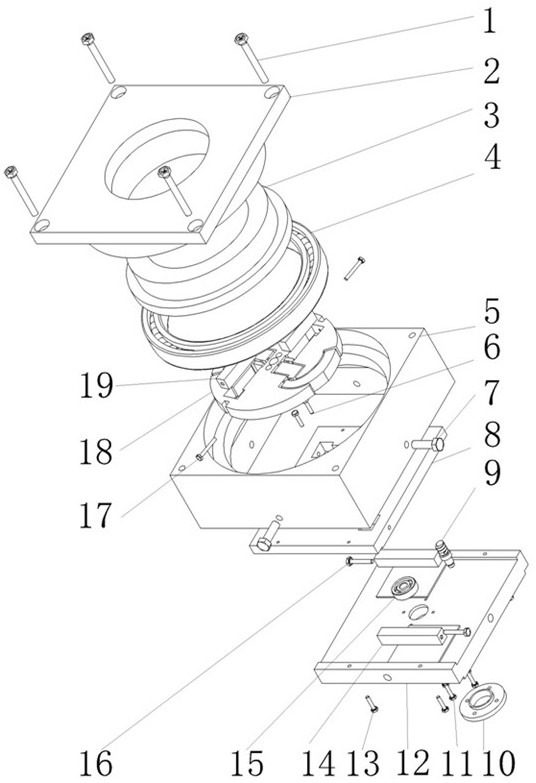

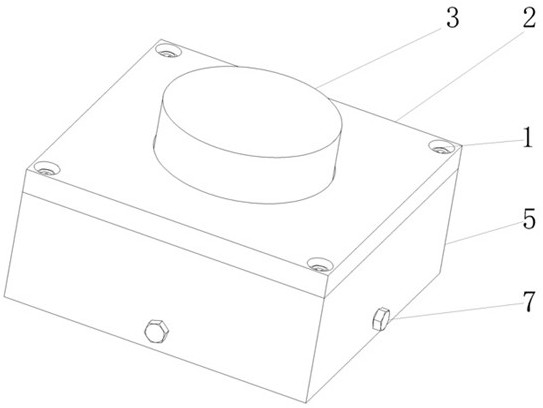

[0031] Such as Figure 1-4 As shown, a multi-stage flexible amplified piezoelectric micromotor, main screw A1, upper cover 2, rotor 3, bearing A4, housing 5, screw B6, screw C7, rotary flexible hinge 8, thread shaft 9, The bearing cover 10, the screw D11, the base 12, the screw E13, the piezoelectric stack A14, the bearing B15, the screws F16, the screw G17, the expansion mechanism 18 and the pressure-stack b19; the upper cover 2, rotor 3, expansion mechanism 18 The rotating flexible hinge 8, the threaded shaft 9 and the base 12 are designed from the top-to-lower sequential laminated layer, and the lower bearing cover 10 is mounted at the center position of the lower surface of the base 12, the bearing end cover 10 passed The screw D11 is fixed on the lower surface of the base shown;

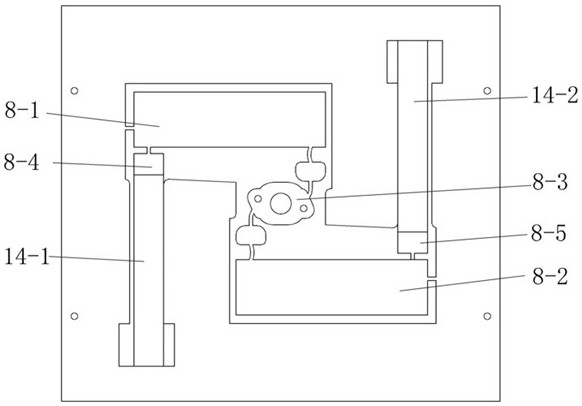

[0032] The rotating flexible hinge 8 is a rectangular structure, mainly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com