An infinitely rotating camera and its method, and a visual inspection system for cold-rolled steel strip

A technology of camera and rotating box, which is applied in the parts of TV system, TV, color TV, etc. It can solve the problems such as difficulty in fine-tuning the shooting angle of the camera, defects in weld image detection, and limited spatial position of the camera, etc., so as to ensure no Omission, small footprint, and the effect of solving limited space and location

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0034] The x-axis direction referred to in the present invention is the left-right direction in the drawings, and the y-axis direction is the up-down direction in the drawings.

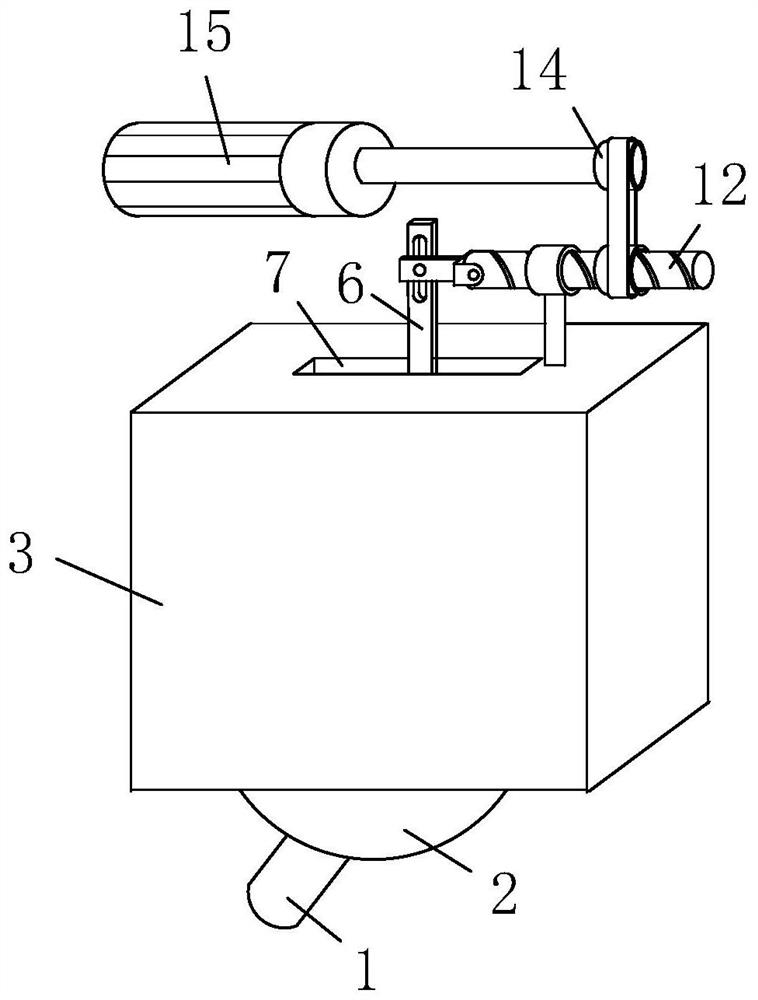

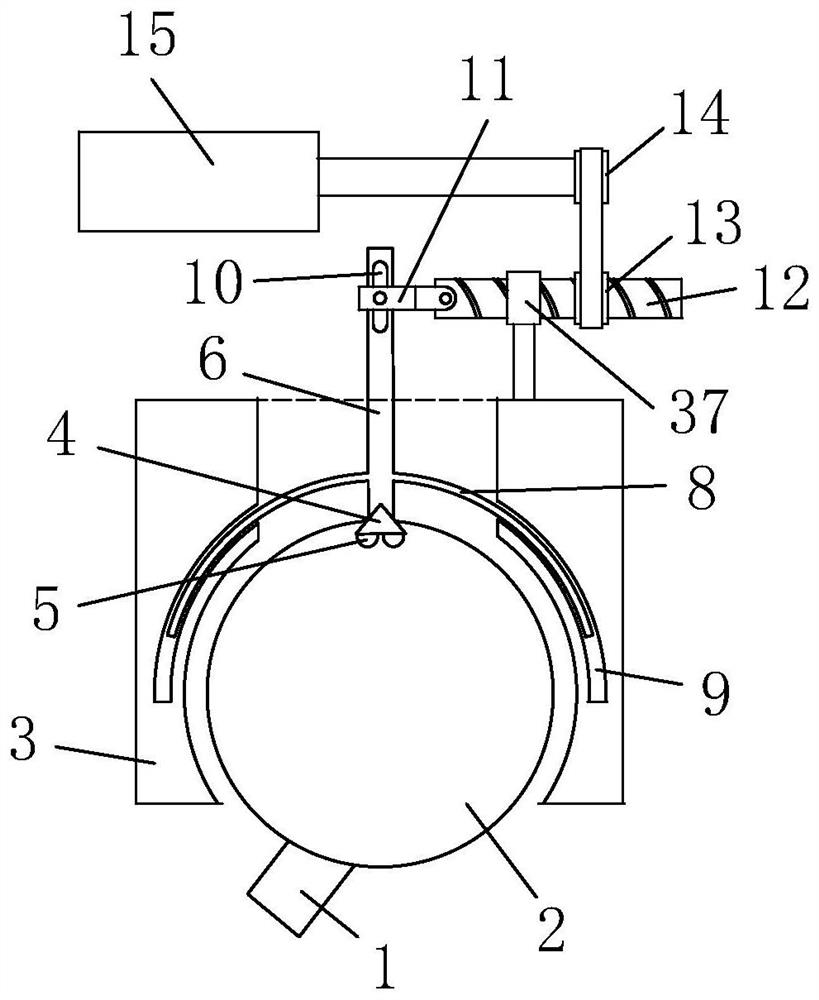

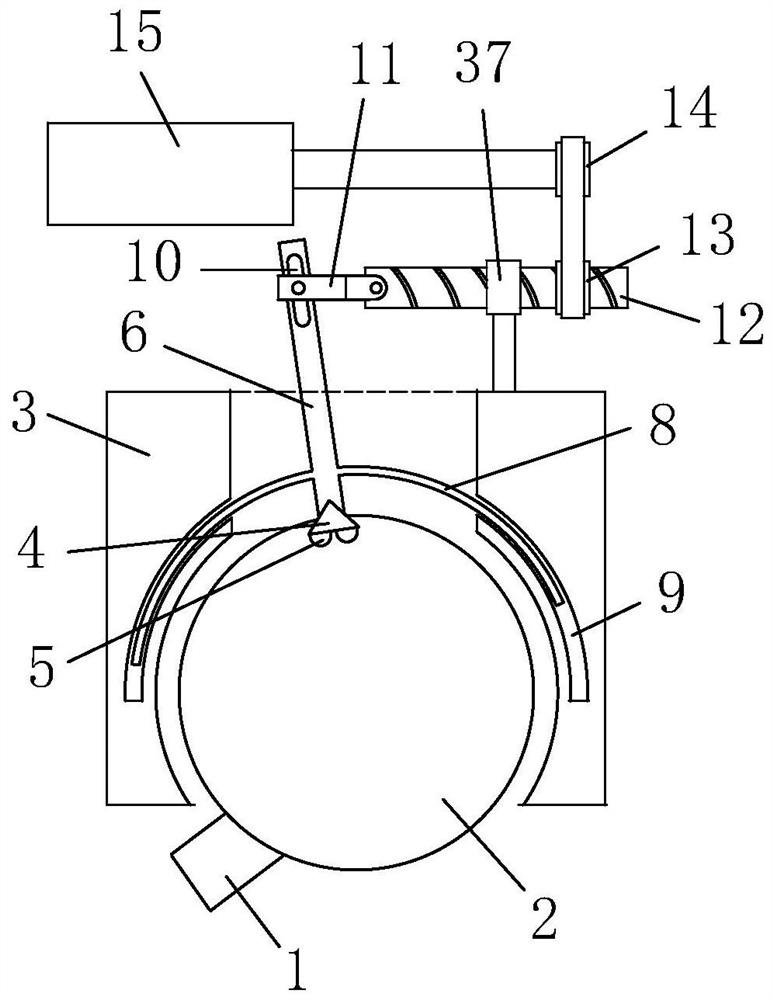

[0035] Such as figure 1 and figure 2 The shown stepless rotating camera includes a lens 1, which is fixedly connected to the bottom end of the stepless turning ball 2, and the stepless turning ball is installed in the stepless turning box 3, and the lower end of the stepless turning box is provided with an opening, so that the part of the stepless turning ball is exposed to the The outside of the box is infinitely turned, and the lens is mounted on the outside. The infinitely rotating ball can rotate relative to the infinitely rotating box. As shown in the figure, the bottom of the infinitely rotating box extends downward beyond the central axis of the infin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com