An automatic feeding device for improving the disease resistance rate and lean meat rate of pigs

A technology of automatic feeding and disease resistance rate, applied in the field of livestock breeding, can solve the problems such as the control of feeding amount can only be estimated by feeding experience, the failure to meet the requirements of scientific management of sows, and the difficulty of artificial feeding method to complete the workload, etc. achieve the effect of avoiding over-delivery or under-delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

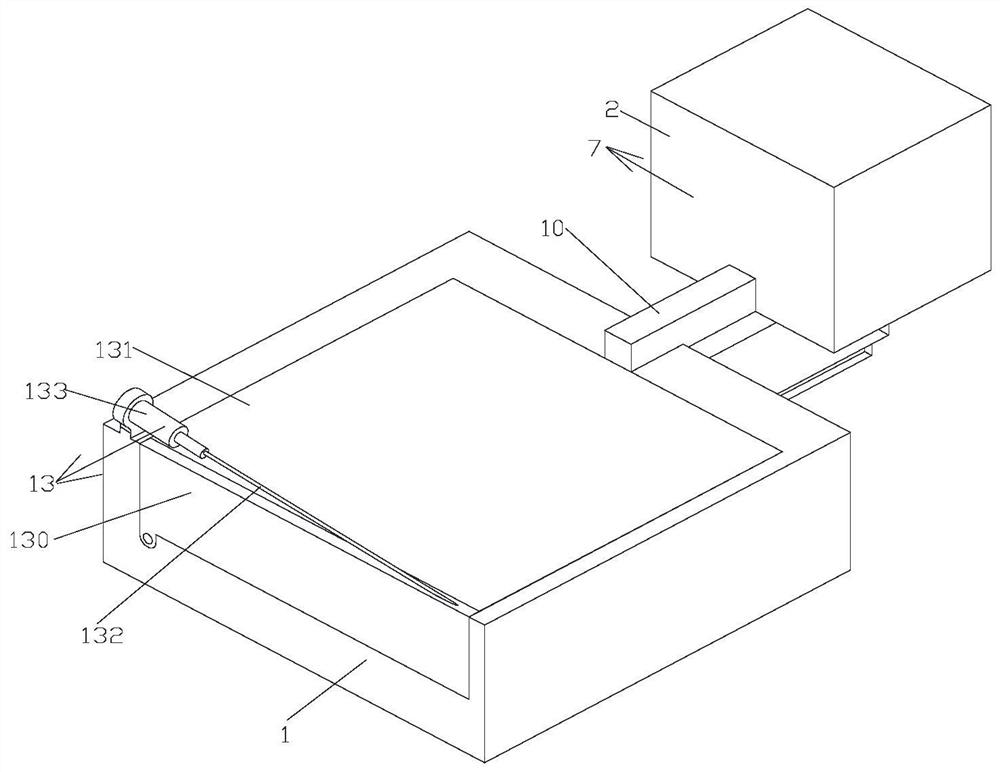

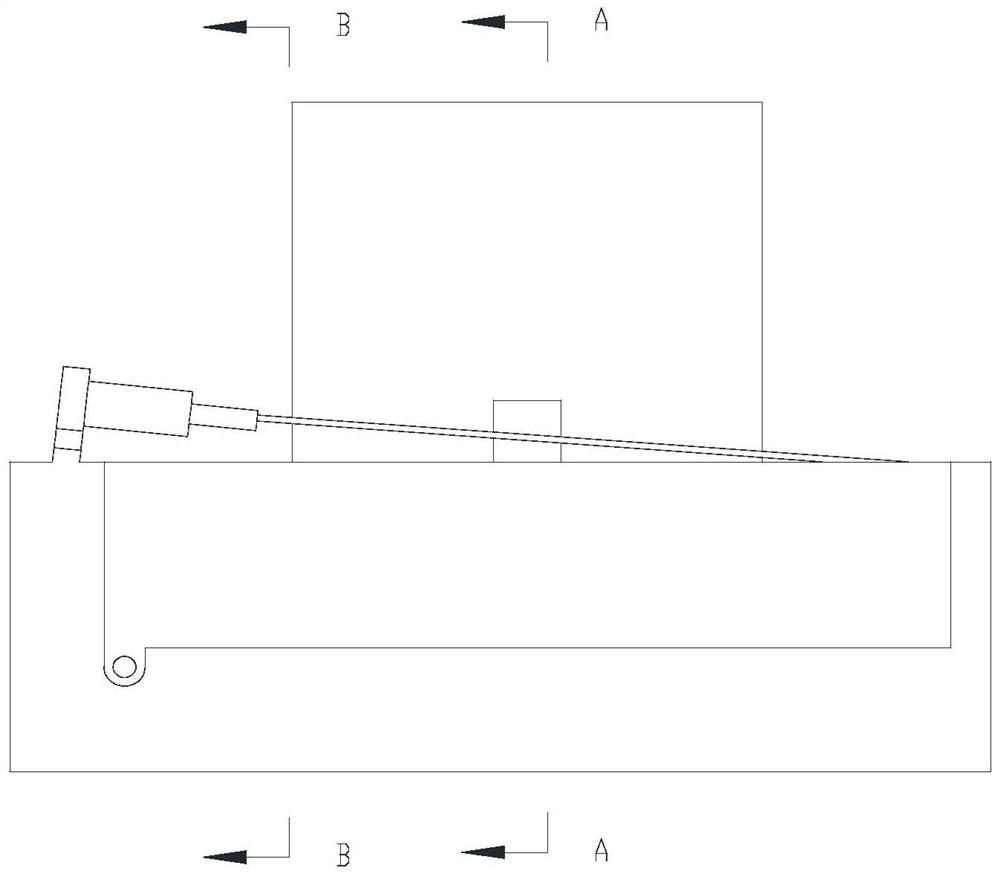

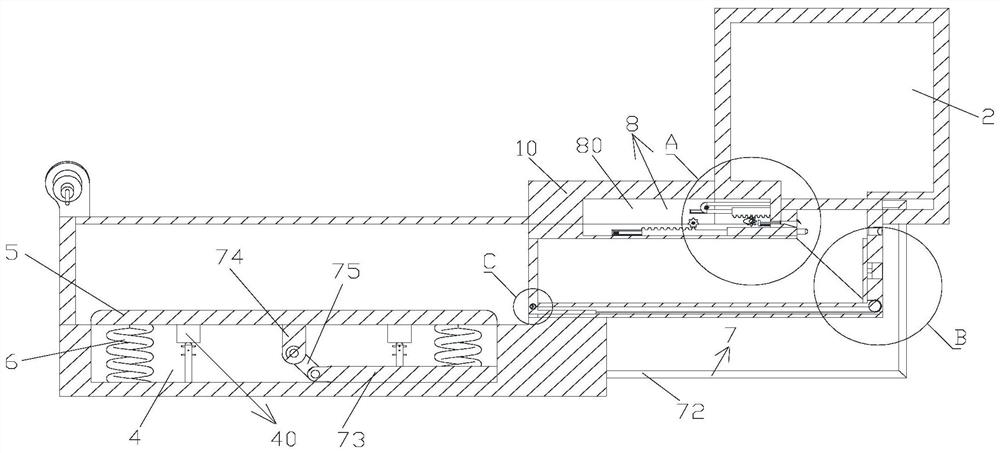

[0037] Such as Figure 1-10 As shown, an automatic feeding apparatus for improving the disease resistance lean rate, including feeding tank 1, storage tank 2, connecting pipe 3, lifting groove 4, lifting plate 5, first spring 6 and discharge device 7 The tank 2 is provided on the side of the feed tank 1; the connection pipe 3 is used to connect the storage tank 2 and the feed tank 1; the rising slot 4 is opened to the feed tank 1; the lifting plate 5 In the feed trough 1, the up or down movement is performed in the lifting groove 4; the first spring 6 is used to connect the lifting plate 5 and the lifting slot 4; the apparatus 7 is provided in the storage tank 2 .

[0038] The apparatus 7 includes a discharge opening 70, a discharge plate 71, a connecting rod 72, and a first link 73; the proof plate 71 is disposed at 70 discharge ports and is performed at the discharge port 70. The front and rear movement; the connecting rod 72 is disposed on the discharge plate 71; the first link ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com