Wax oil wiping device for oak table

A wood wax oil and table technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of not being able to collect wax, and not be able to wipe wax on oak tables at the same time, so as to achieve good placement, save physical consumption, improve The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

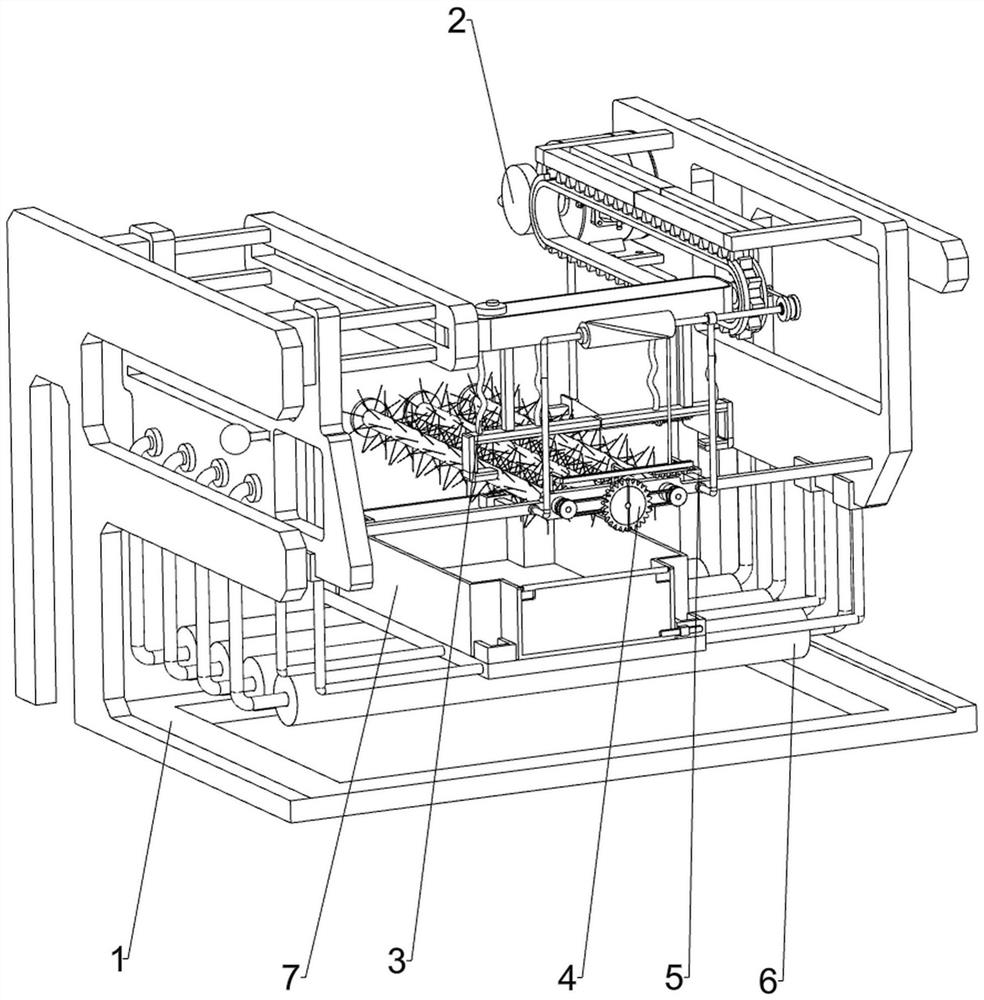

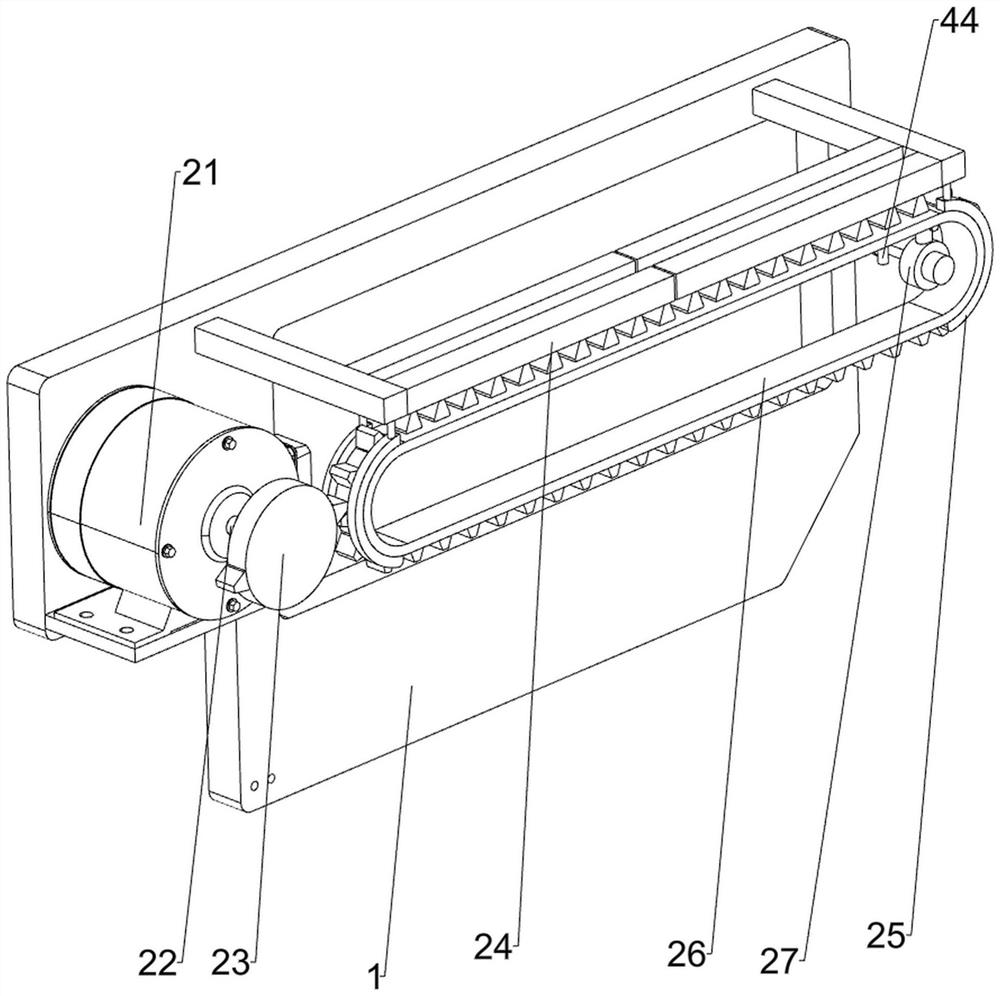

[0025] An oak table wiped wood wafer device, such as Figures 1 to 7 As shown, including the rack 1, the driving assembly 2, the first wiper assembly 3 and the second wiper assembly 4, the frame 1 is used to mount the entire device, and the upper right upper right side of the rack 1 is provided to move. The drive assembly 2, the upper portion of the frame 1 is provided with a first wiking assembly 3 by a sliding manner, and the first wipe assembly 3 is connected to the drive assembly 2, and the lower portion of the rack 1 is provided with a rotation mode. The second wetting assembly 4 of the wax wax.

[0026] When you need to wipe the oak table, first place the oak table below the first wiper assembly 3, and the second wiper assembly 4 is located above the oak table, and then a quantity of the second wiper assembly 4. Wax oil, that is, the drive assembly 2 can be operated, and the first wiper assembly 3 and the second wi-wax assembly 4 will wax the oak table, after the oak table is...

Embodiment 2

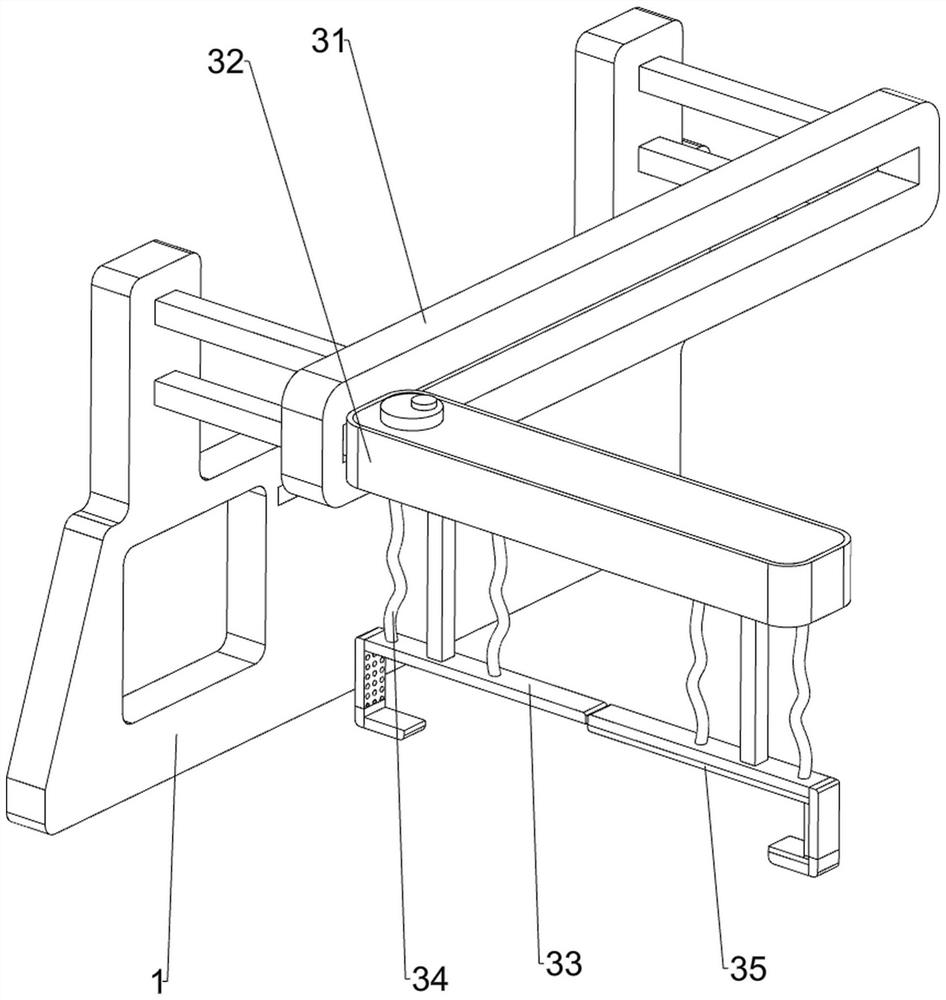

[0034] On the basis of Example 1, such as figure 1 with Figure 5 The fixing assembly 5 is also included, and the fixing assembly 5 includes a U-shaped block 51, a slider 52, a tension spring 53, a wedge-shaped block 54, and a push rod 55, and the U-shaped block 51 has two, and the rear side of the fixed bar 41. By the screw is firmly connected with the U-shaped block 51, the slider 52 has two, the rack 1 is slidably equipped with the slider 52, and the sliding rod 52 and the frame 1 are connected to the tension spring 53, the slider 52 A wedge block 54 is provided between the ends, the lower side sliding type of the rack 1 is provided with push rod 55, and the push rod 55 is fitted to the teeth 26, and the push rod 55 is fitted with the wedge block 54.

[0035] When the staff moves the oak table to contact with the U-shaped block 51, the staff can push or pull the oak table, and then push the push rod 55 downward when the tape 26 is in contact with the push rod 55, and drive the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com