Vitrified brick and processing method and system thereof

A processing system and technology of vitrified bricks, applied in metal processing equipment, manufacturing tools, grinding workpiece supports, etc., can solve the problems of exposed hair pores, high water absorption rate of vitrified bricks, easy penetration of oil and dust, etc., to achieve Prevents the penetration of oil or dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

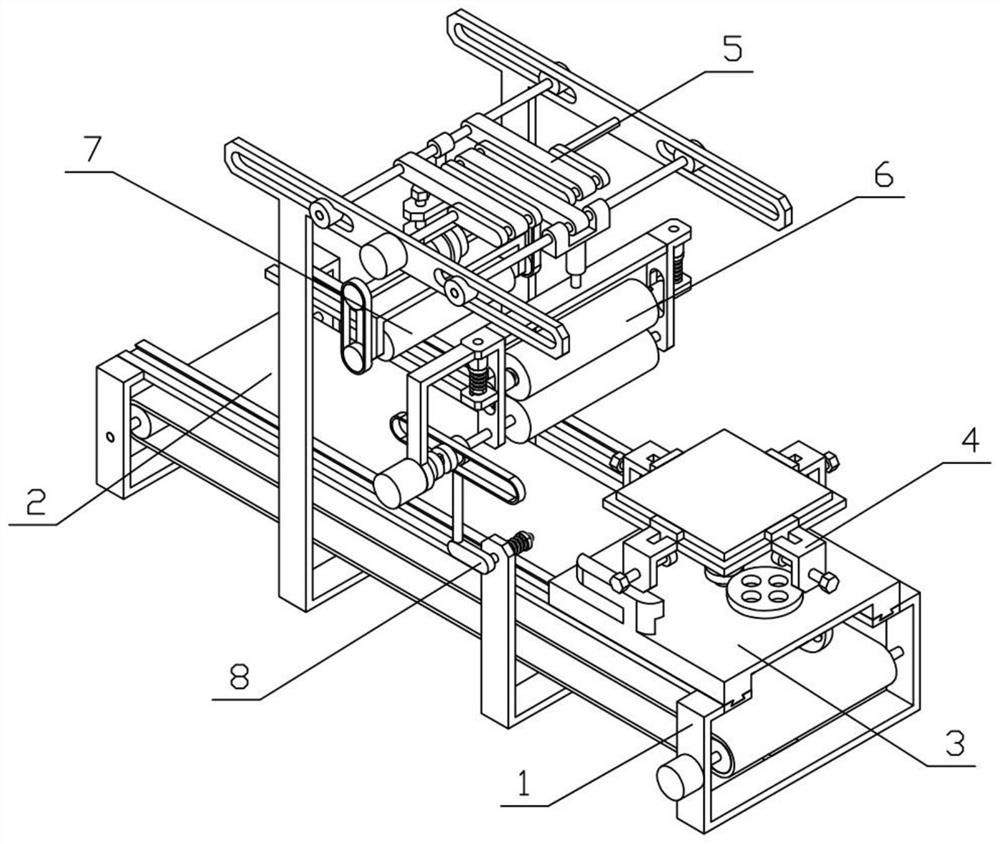

[0037] Combine below Figure 1-10Describe this embodiment, a vitrified tile processing system, including a processing support 1, a transport mechanism 2, a processing platform 3, a clamping mechanism 4, a reciprocating mechanism 5, a waxing mechanism 6, a polishing mechanism 7, and a pushing fork 8. The transportation mechanism 2 is connected to the processing support 1, the processing platform 3 is slidably connected to the processing support 1, the clamping mechanism 4 is connected to the processing platform 3, the reciprocating mechanism 5 is connected to the middle part of the processing support 1, and the processing support 1 is slidably connected to There are waxing mechanism 6 and polishing mechanism 7, both of waxing mechanism 6 and polishing mechanism 7 are hinged on the reciprocating mechanism 5, and the pushing fork 8 is slidably connected to the processing support 1, and the pushing fork 8 is fixedly connected with the processing support 1 There is a compression sp...

specific Embodiment approach 2

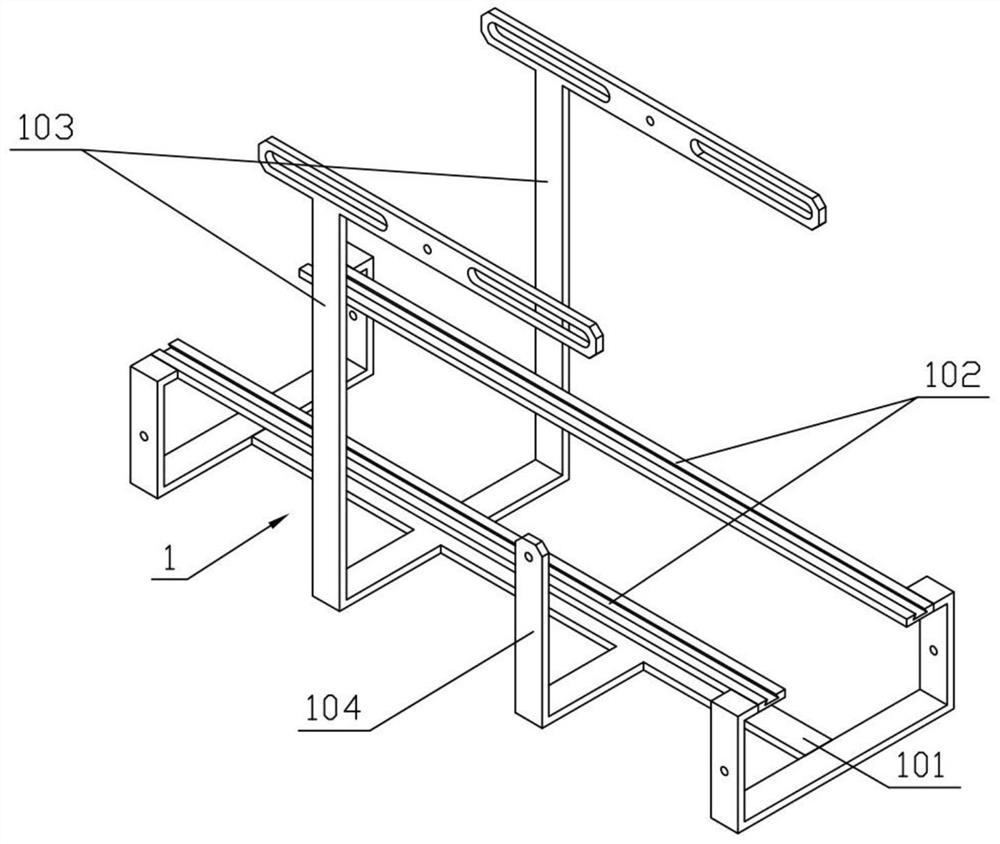

[0039] Combine below Figure 1-10 Illustrate this embodiment, this embodiment will further explain embodiment one, described processing support 1 comprises transport support 101, motion track 102, reciprocating support 103 and pushing support 104, is fixedly connected with two movement tracks 102 on the transport support 101, A reciprocating support 103 is fixedly connected to the middle part of the transport support 101 , and a push support 104 is fixedly connected to the transport support 101 .

specific Embodiment approach 3

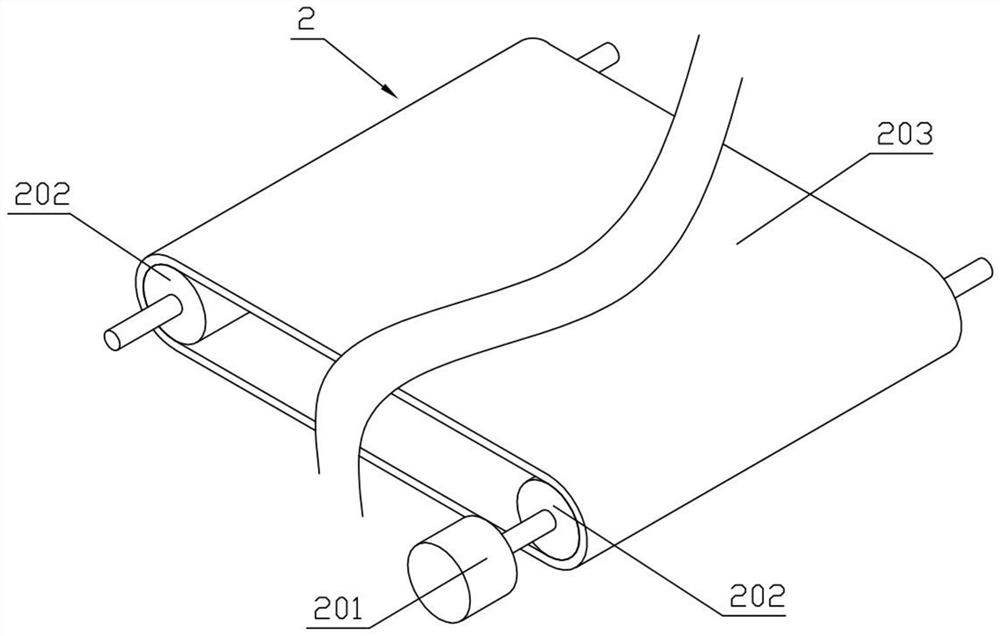

[0041] Combine below Figure 1-10 Illustrate this embodiment, this embodiment will further explain the second embodiment, the transportation mechanism 2 includes a transportation motor 201, a transportation wheel 202 and a transportation belt 203, two transportation wheels 202 are provided, and the two transportation wheels 202 pass through The transport belt 203 is connected in transmission, the transport motor 201 is fixedly connected to the transport support 101 , and the output shaft of the transport motor 201 is in transmission connection with one of the transport wheels 202 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com