Cooling bed rolled piece clamping and braking device

A rolling piece and cooling bed technology, which is applied in the field of cooling bed rolling piece clamping and braking devices, can solve the problems of too long braking distance and low utilization rate of cooling bed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

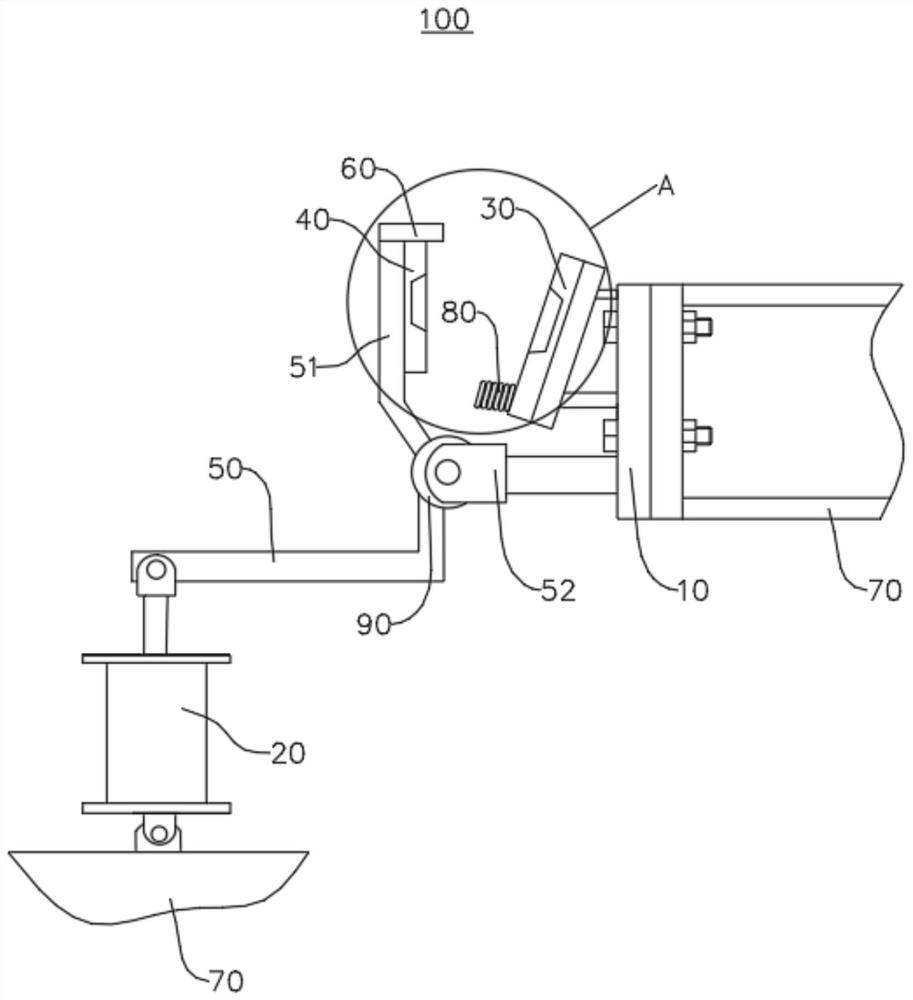

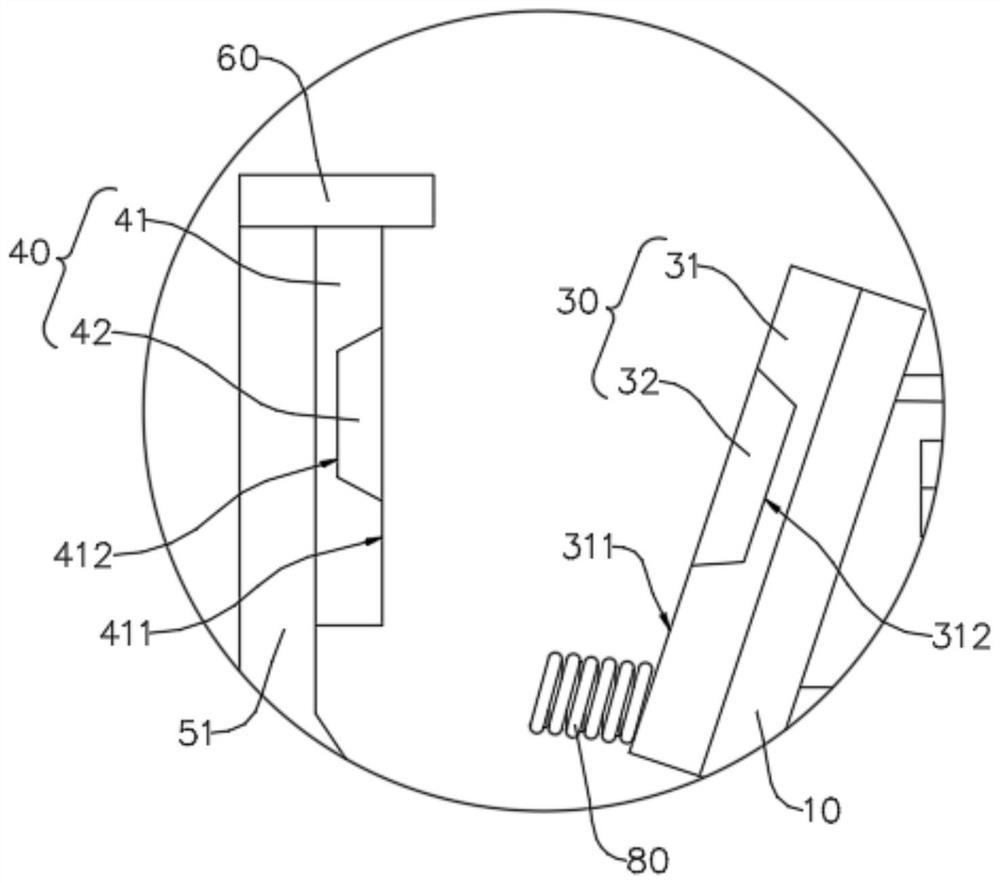

[0035] The embodiment of the present application provides a clamping and braking device 100 for rolled pieces on a cooling bed, which can improve the problem in the prior art that the braking distance of the rolled piece on the cooling bed is too long, which leads to a very low utilization rate of the cooling bed. The following will be combined with the accompanying drawings The specific structure of the clamping and braking device 100 for the cold bed rolled piece will be described in detail.

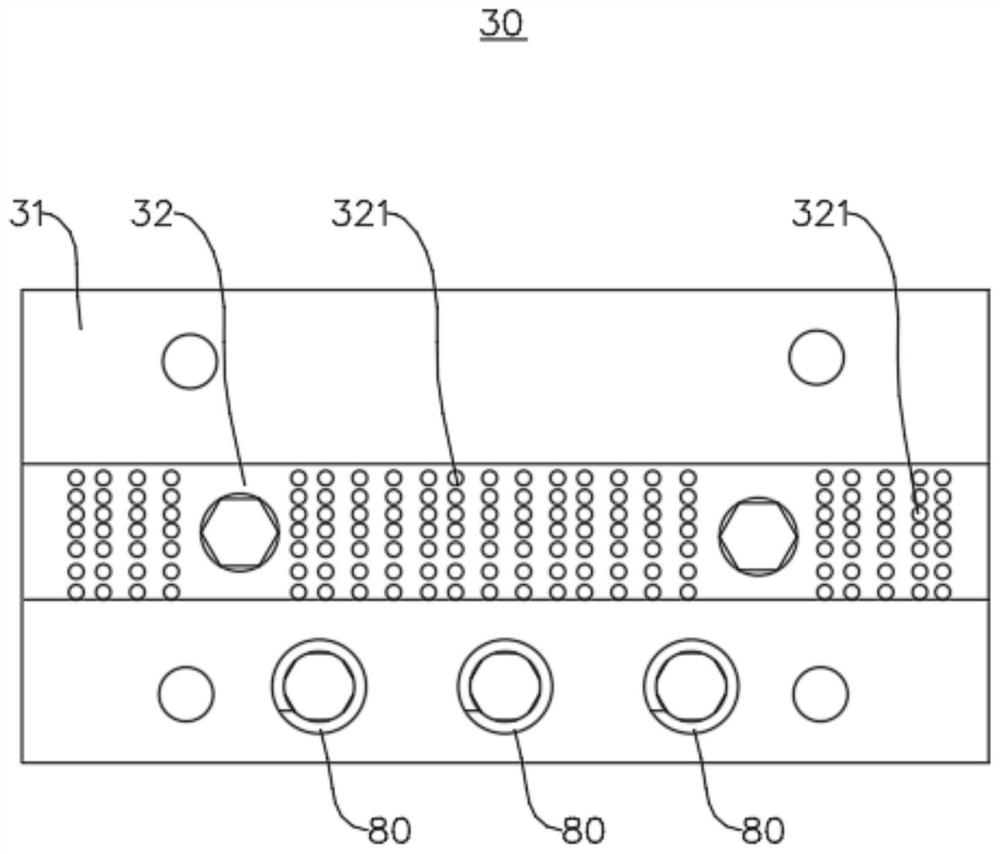

[0036] Such as figure 1 As shown, the clamping and braking device 100 for cold bed rolling stock includes a mounting base 10 , a driving mechanism 20 , a first clamping brake plate 30 , a second clamping brake plate 40 , a swing arm 50 and a blocking plate 60 . The mounting base 10 is used to be installed on the frame of the cooling bed 70 , and the first brake plate 30 is mounted on the mounting base 10 . The swing arm 50 is swingably connected to the mounting base 10 , and the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com