Junction box grabbing and assembling mechanism and photovoltaic bus bar assembling and bending device

A technology of assembling mechanism and junction box, which is applied to photovoltaic modules, feeding devices, positioning devices, etc., can solve problems such as affecting use, and achieve the effects of preventing wrong bending, tight structural coordination, and preventing center of gravity from shifting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

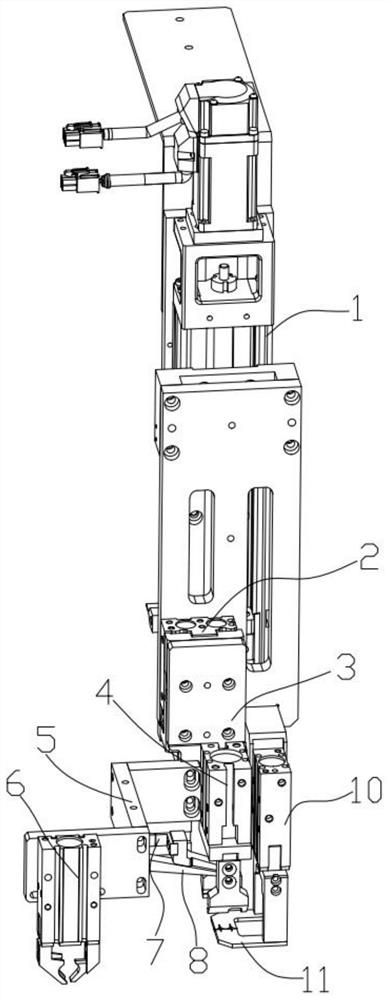

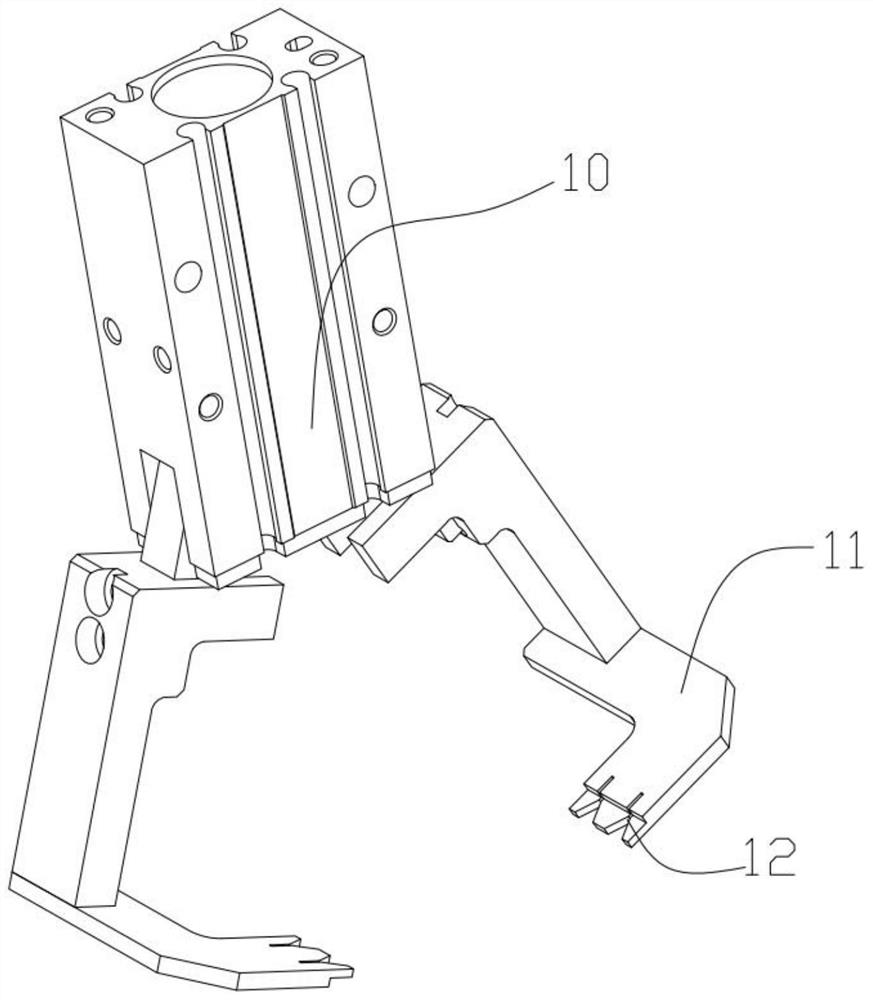

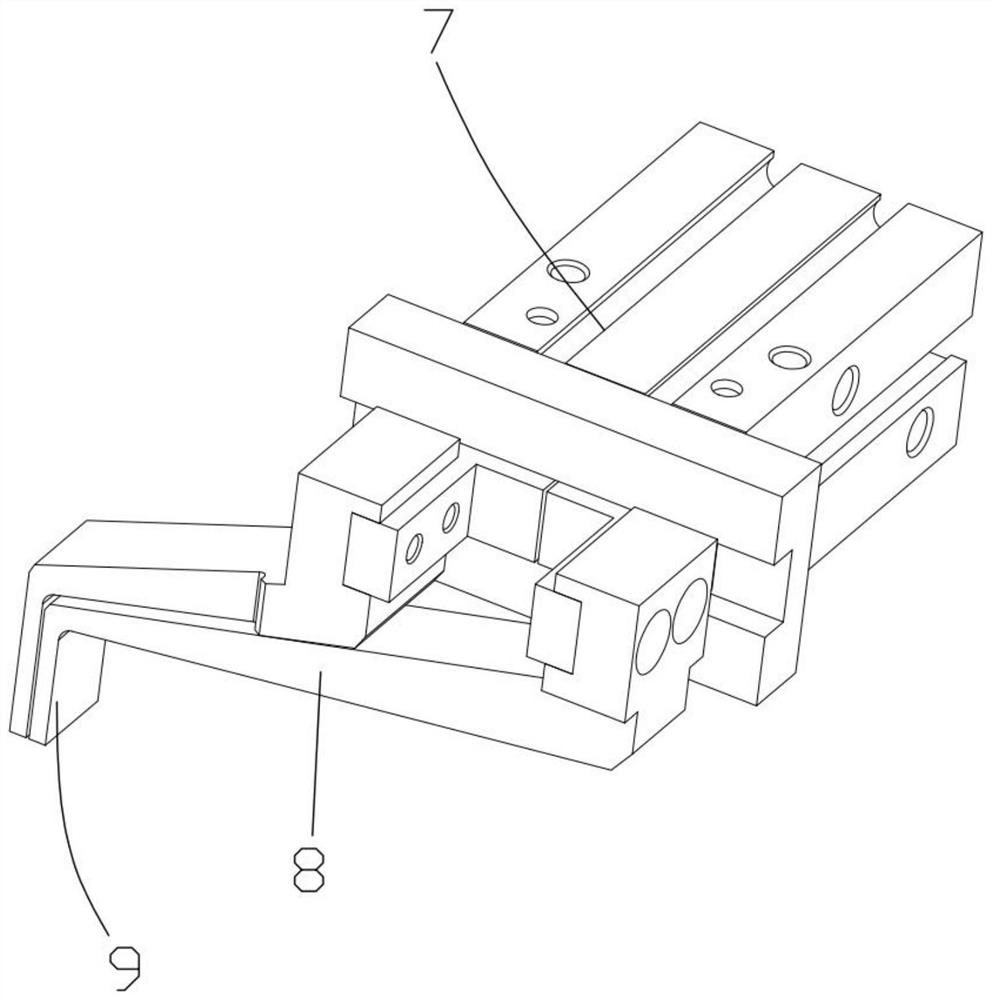

[0023] Such as Figure 1-Figure 3 As shown, the present invention proposes a junction box grasping and assembling mechanism, including a lifting mechanism 1, which is provided with a downward pressure cylinder 2, and the lifting mechanism 1 is a screw module, which is used to lower the entire grasping Up and down movement when taking the product, the output end of the press-down cylinder 2 is connected to a mounting plate 3, the mounting plate 3 is provided with a first jaw cylinder 4, and a bus bar is provided on the side of the first jaw cylinder 4 The positioning mechanism, the bus bar positioning mechanism is fixedly connected with the lifting mechanism 1, the lifting mechanism 1 is provided with a fixed plate, and the bus bar positioning mechanism is connected with the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com