Grinding clamp for aviation turbine blade tenon

A technology for aviation turbines and blade tenons, which is applied in the direction of grinding workpiece supports, etc., can solve problems such as low production efficiency and insufficient positioning accuracy of fixtures, and achieve the effect of improving processing efficiency and processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

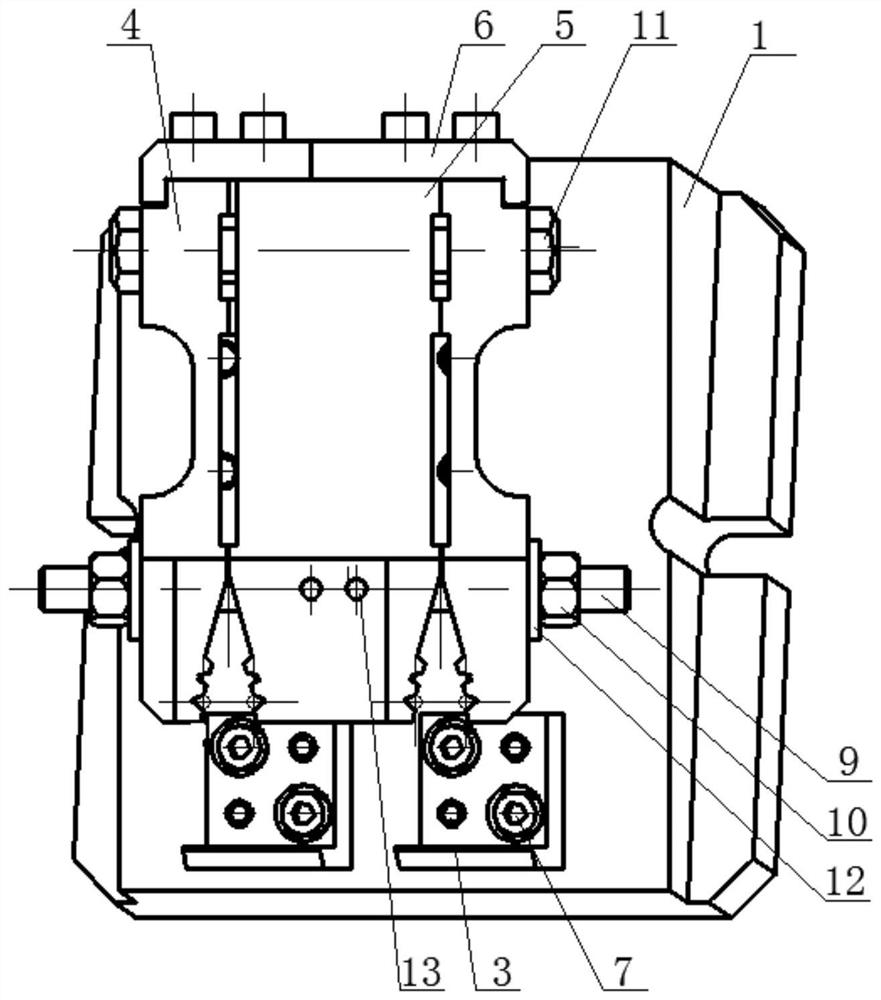

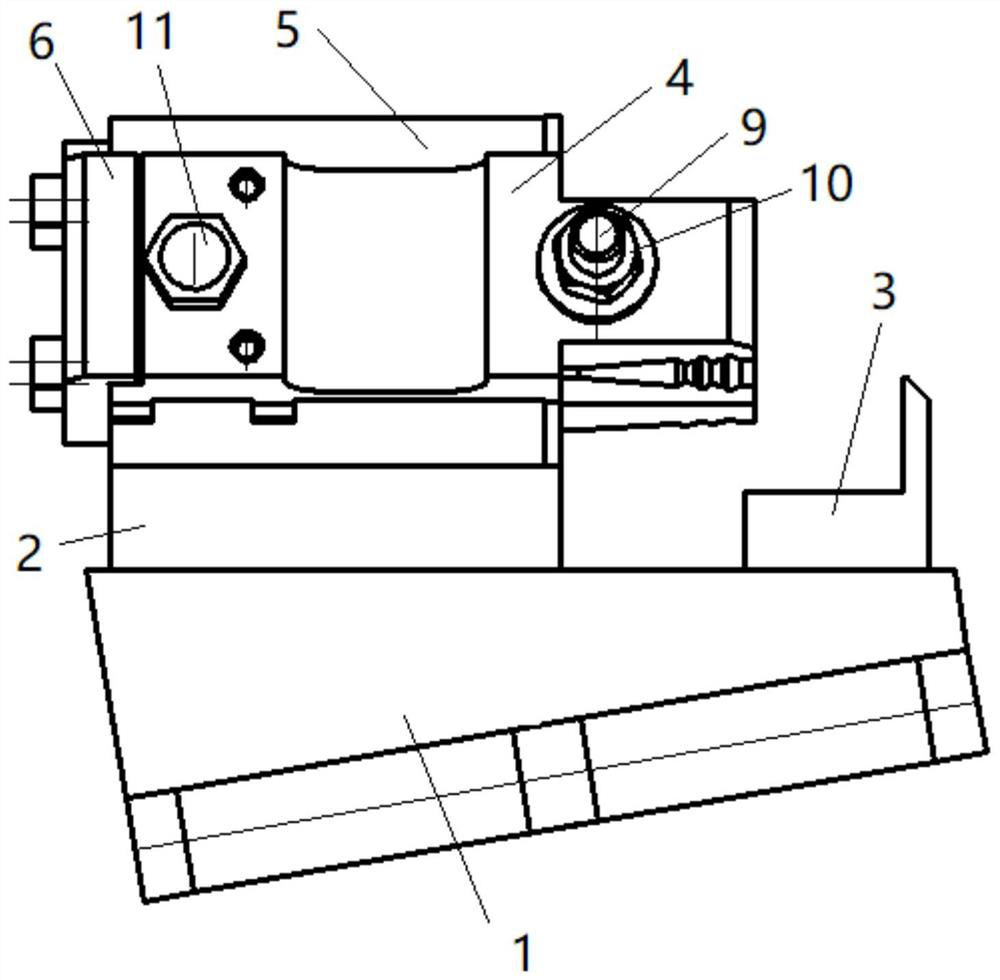

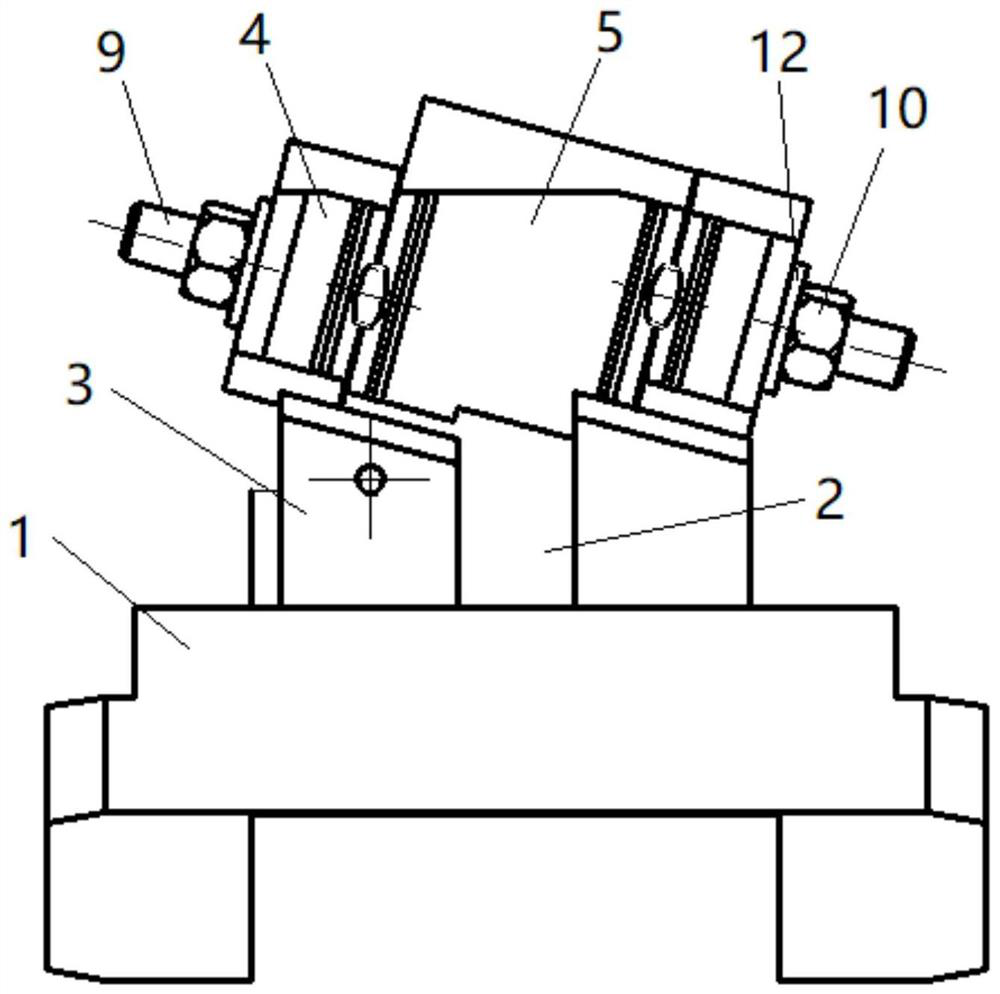

[0036] Such as Figure 1-Figure 3 As shown, this embodiment provides a grinding jig for aviation turbine blade tenons, including: a base 1 and a plurality of clamping components.

[0037] The upper surface of the base 1 is a horizontal plane, the lower surface of the base 1 is an inclined surface, and the lower surface of the base 1 is used for being installed on an external machine tool. Multiple clamping parts are used to clamp the aviation turbine blades, and the multiple clamping parts are obliquely connected to the upper surface of the base 1 , and the inclination directions of the multiple clamping parts are in an orthogonal relationship with the inclination direction of the base 1 .

[0038] Among them, the base 1 is used for fitting and installing with an external machine tool. At the same time, the inclined design of the lower surface of the base 1 ensures the oblique grinding of the tenon of the aviation turbine blade, and realizes the inclination of the tenon of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com