Batch stamping system

A batch, one-to-one technology, applied in printing, printing device, stamping and other directions, can solve the problem of increasing the labor load of accountants, and achieve the effect of reducing the workload, improving the stability of use and smooth movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

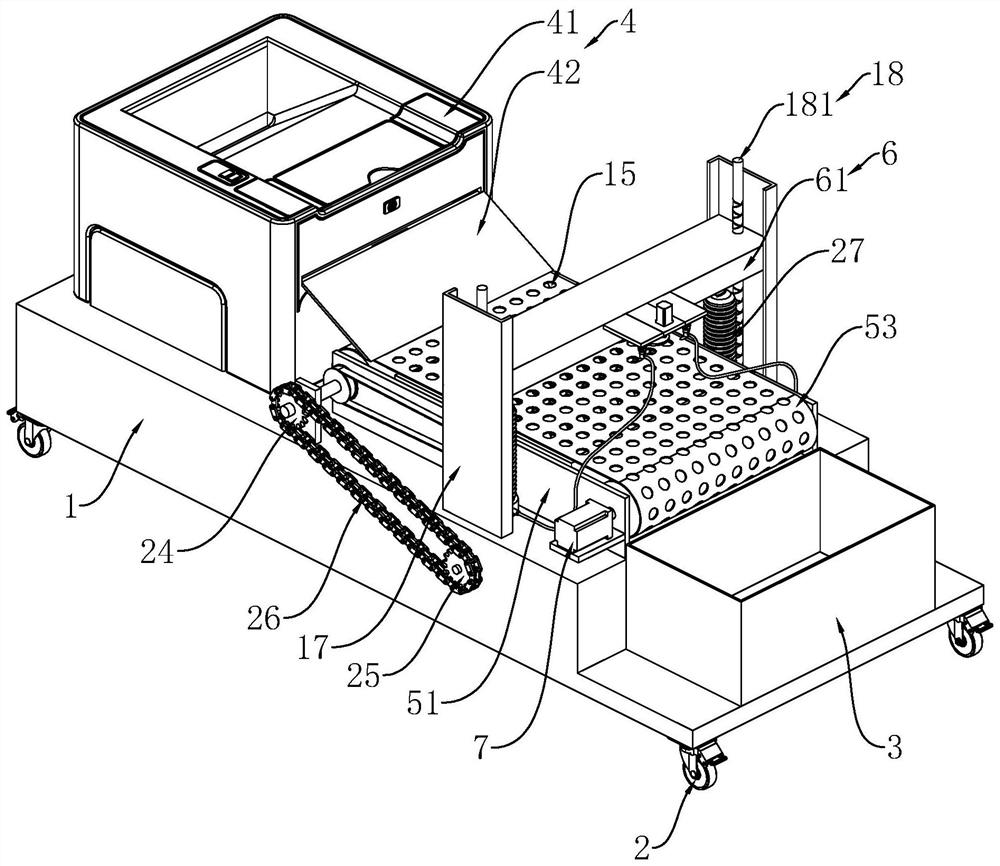

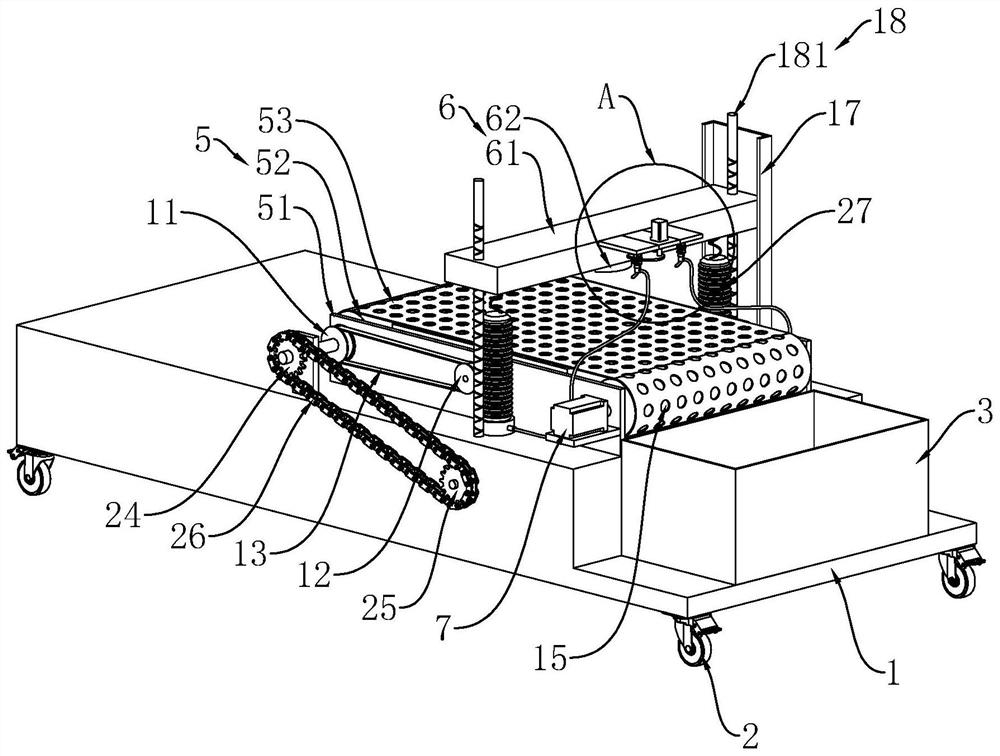

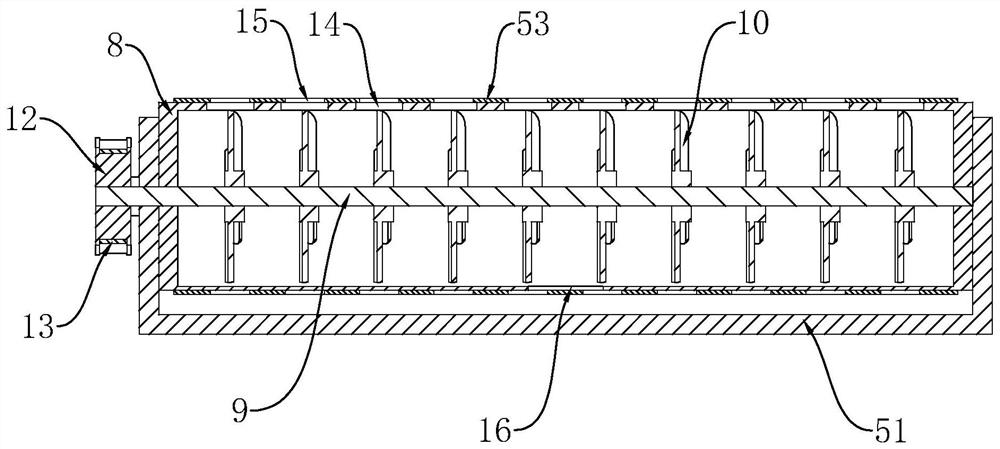

[0038] refer to figure 1 with figure 2 , a batch stamping system, including a horizontally arranged workbench 1, the four corners of the lower end surface of the workbench 1 are respectively fixedly connected with universal wheels 2 with brakes. The upper end surface of the workbench 1 is provided with a paper feeding mechanism 4 , a conveying mechanism 5 and a seal mechanism 6 in sequence, and the upper end surface of the workbench 1 is provided with a receiving box 3 located at one side of the seal mechanism 6 .

[0039] When a large batch of documents needs to be stamped, the documents are sent to the conveying mechanism 5 sequentially through the paper feeding mechanism 4, and then the documents are transported through the conveying mechanism 5. Subsequently, the documents are sequentially stamped by the stamping mechanism 6, and finally the documents ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com