Power assembly suspension bushing

A technology of powertrain and bushing, which is applied in the direction of power unit, electric power unit, non-rotational vibration suppression, etc. It can solve the problems of torsional deformation of rubber parts, changes in suspension performance, and failure to work normally.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

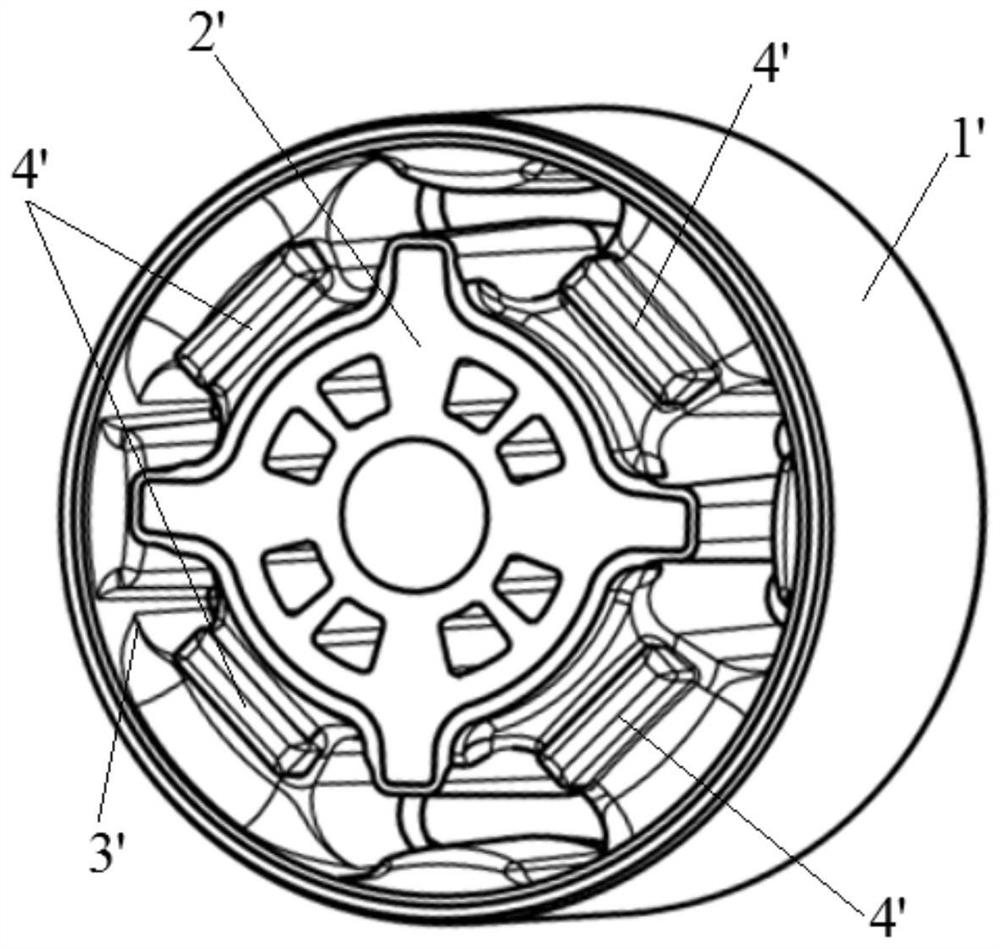

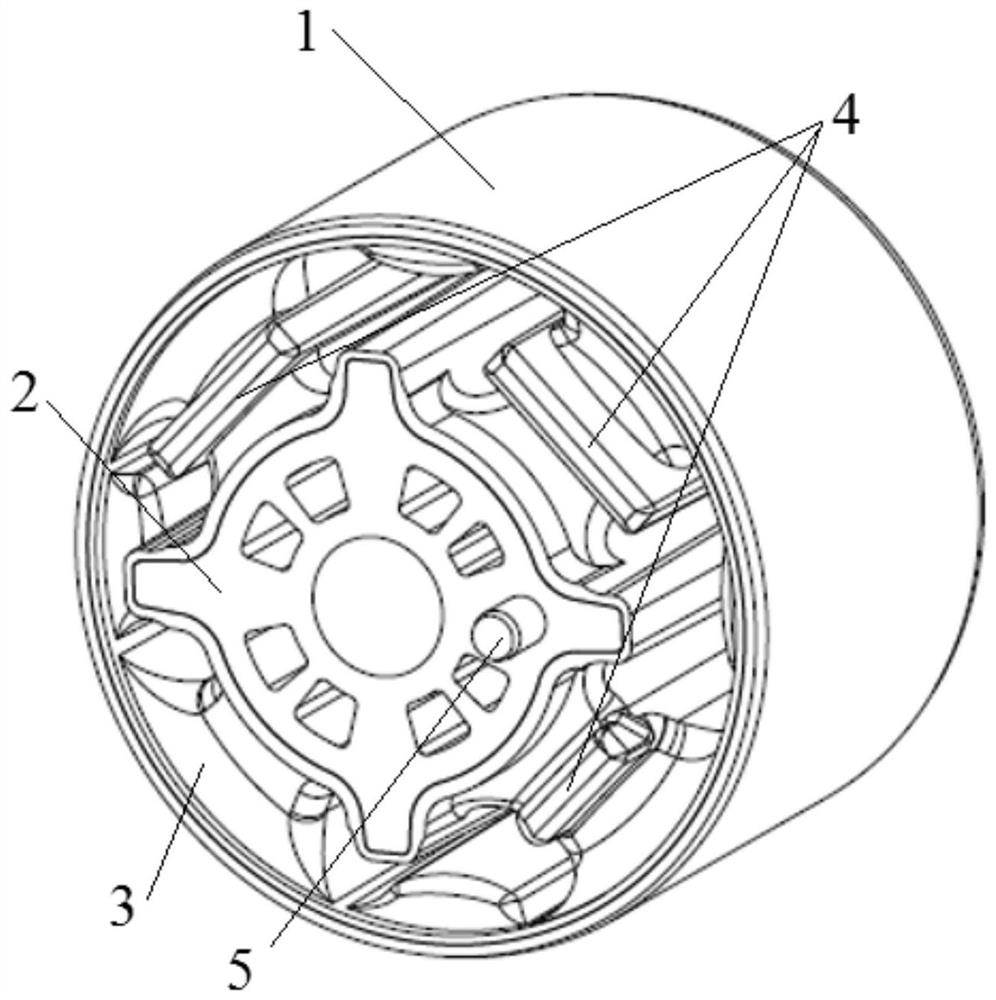

[0026] see image 3 with Figure 4 , a powertrain suspension bushing, including an inner casing 2, an anti-rotation pin 5, an outer casing 1, a rubber main spring 3 and several vibration isolation blocks 4 arranged on the rubber main spring 3.

[0027] The inner casing 2 and the outer casing 1 are arranged coaxially from the inside to the outside; the rubber main spring 3 is arranged between the inner casing 2 and the outer casing 1, and the inner casing 2 and the outer casing 1 are partially vulcanized and connected by the rubber main spring 3 together; the inner casing 2 is provided with an anti-rotation pin installation hole; the anti-rotation pin 5 is press-fitted into the anti-rotation pin installation hole through interference fit; the vibration isolation block is composed of rubber protrusions on the rubber main spring 3; The vibration isolation blocks 4 are asymmetrically distributed on the rubber main spring 3 , and the vibration isolation blocks 4 have different sha...

Embodiment 2

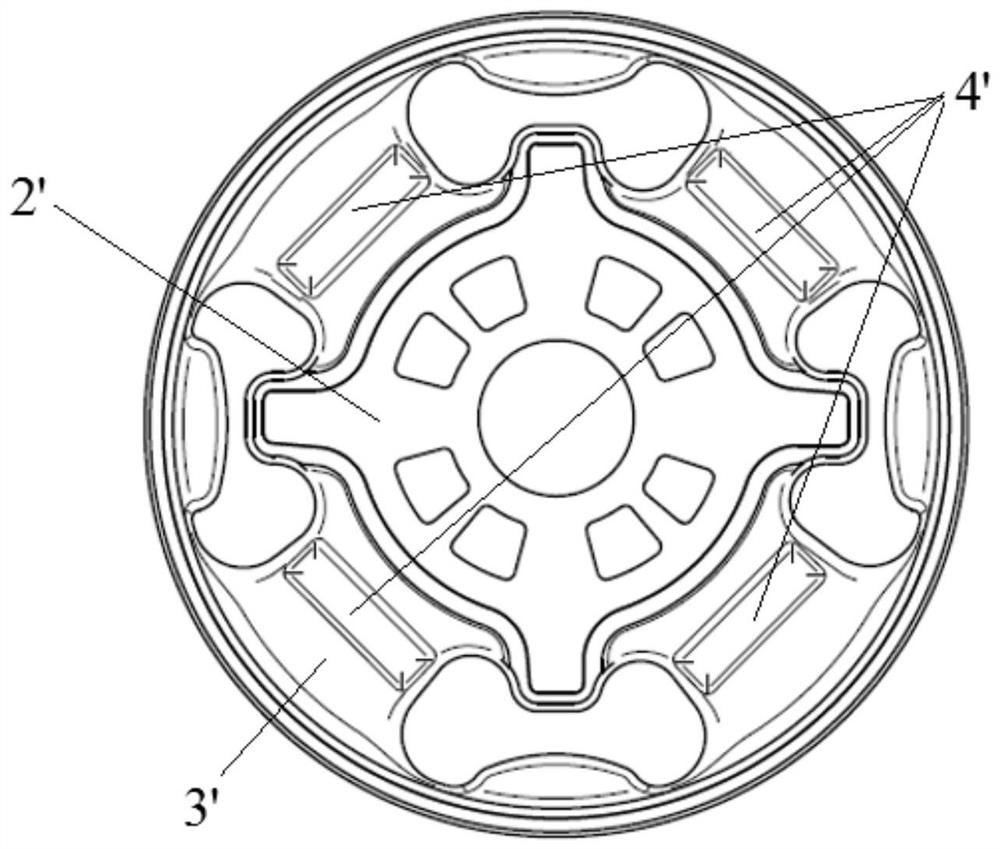

[0030] see Figure 5 with Image 6 , a powertrain suspension bushing, the difference from Embodiment 1 is that the main rubber spring 3 has an annular columnar structure, and vibration isolation blocks 4 are distributed on at least one end surface of the main rubber spring 3 . The number, shape, size and position of the vibration isolation blocks 4 in the main vibration isolation direction are different, reflecting the characteristics of asymmetrical layout.

[0031] see Figure 7 , the high-frequency dynamic stiffness 100 of the design scheme of the powertrain suspension bush of the present invention is symmetrical with the high-frequency dynamic stiffness 200 of the design scheme of the suspension bush without vibration isolation blocks in the prior art. The high-frequency dynamic stiffness of the design scheme of the suspension bushing of the distributed vibration isolation blocks is compared with 300, and the results show that: the powertrain suspension bushing of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com