Annular vibration reduction axle box with temperature measuring hole

A technology of damping shafts and temperature measuring holes, which is applied to axle boxes, railway vehicle shape measuring devices, railway car body parts, etc., can solve the problems of complex manufacturing process, high manufacturing and maintenance costs, flying sand and gravel impact, etc. Achieve the effects of improving the strength of the mechanical structure, reducing the shape and size, and ensuring the vibration reduction index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

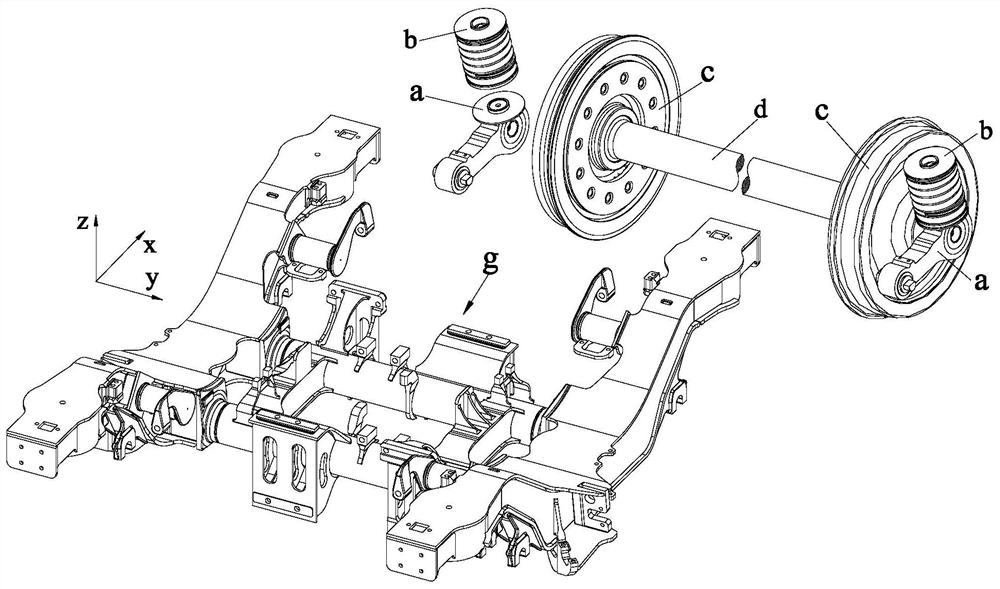

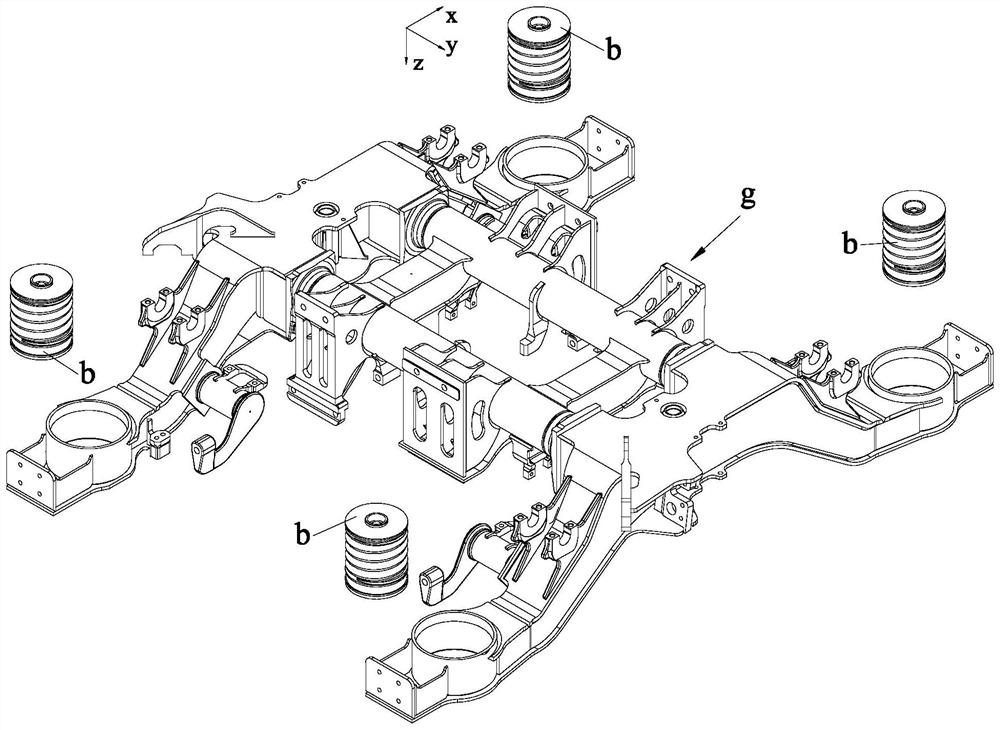

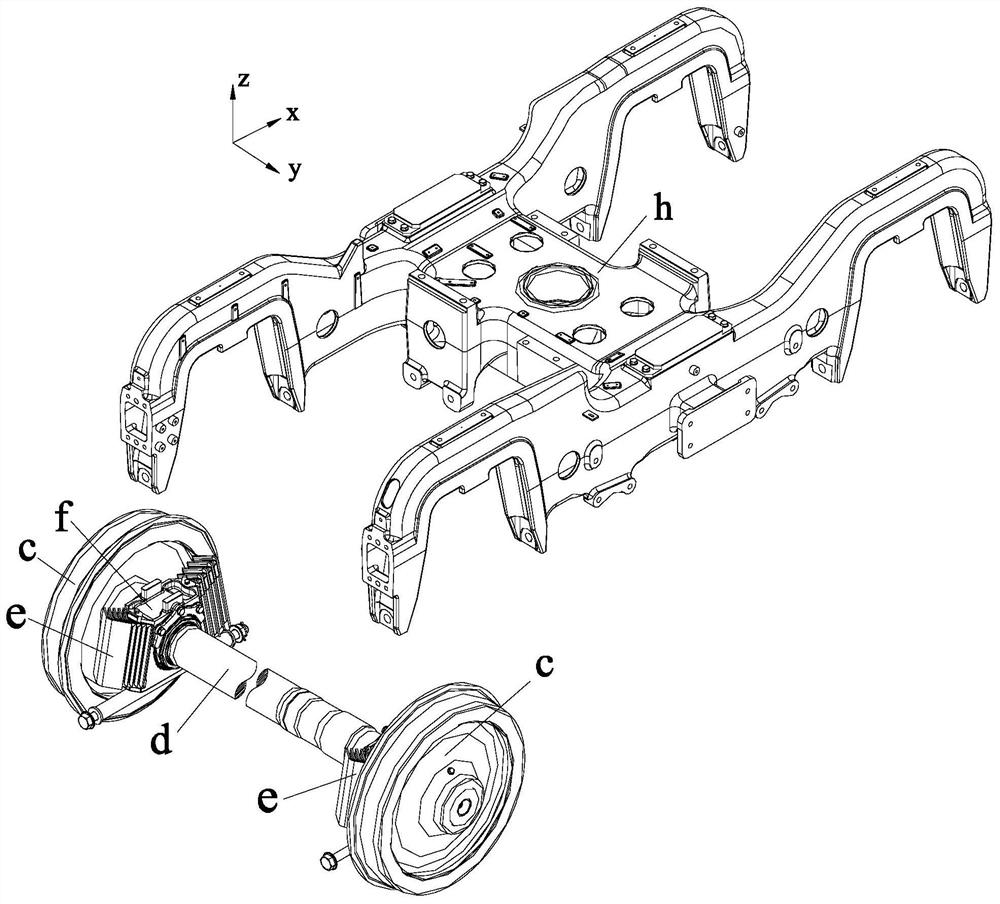

[0019] Such as Figure 4 to Figure 9 As shown, the annular damping axlebox with temperature measuring holes of the present invention includes axle bearing B-2, axlebox positioning and temperature measuring heat conduction sheath B-3 and vibration damping rubber ring B-1, axlebox positioning and measuring The temperature and heat conduction sheath B-3 is coaxially fixed with the outer ring of the axle bearing B-2, and the inner ring of the axle bearing B-2 is coaxially press-fitted and fixedly connected to both ends of the axle d. The axle box positioning and temperature measurement and heat conduction protection The upper part of the sleeve B-3 and the damping rubber ring B-1 is provided with a socket for positioning the temperature sensor G.

[0020] Axis box positioning and temperature measurement and heat conduction sheath B-3 shell socket B-3-1 and rubbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com