Medical amoxicillin capsule batch boxing equipment

A technology for amoxicillin capsules and medical use, applied in packaging and other directions, can solve the problems of high labor intensity, large workload and low packaging efficiency, and achieve the effect of reducing labor intensity, reducing workload and improving packaging efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

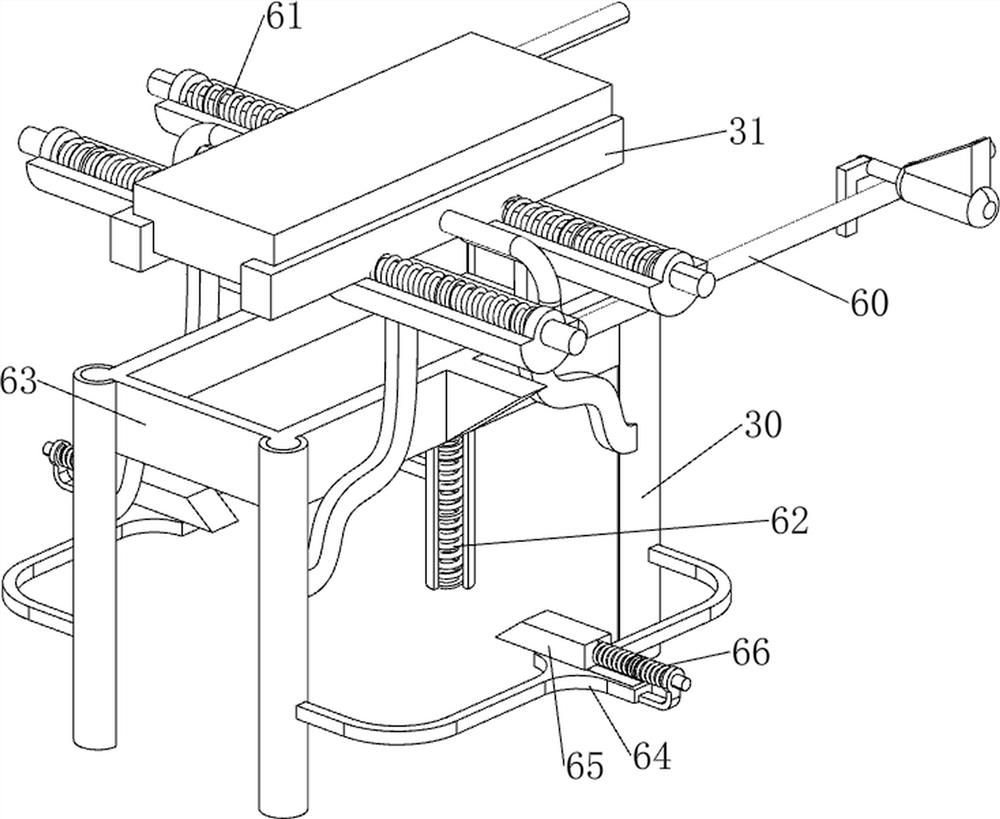

[0030] A kind of medical amoxicillin capsule batch packing equipment, such as Figure 1-2 As shown, it includes a base 1, a propelling mechanism 2 and a clamping mechanism 3, and the propelling mechanism 2 and the clamping mechanism 3 are installed on the base 1 respectively.

[0031] Propelling mechanism 2 comprises cylinder 20, charging box 21, limit plate 22, first spring 23 and push rod 24, and base 1 top right side is equipped with cylinder 20, and base 1 top is connected with charging box 21, and charging box 21 is positioned at the left side of cylinder 20, and the left and right sides of charging box 21 are all slidingly connected with limiting plate 22, and four first springs 23 are connected between limiting plate 22 and charging box 21, and the expansion rod of cylinder 20 A push rod 24 is connected to the top, and the push rod 24 is slidably connected with the charging box 21 .

[0032] The clamping mechanism 3 includes a support frame 30, a splint 31 and a guide ...

Embodiment 2

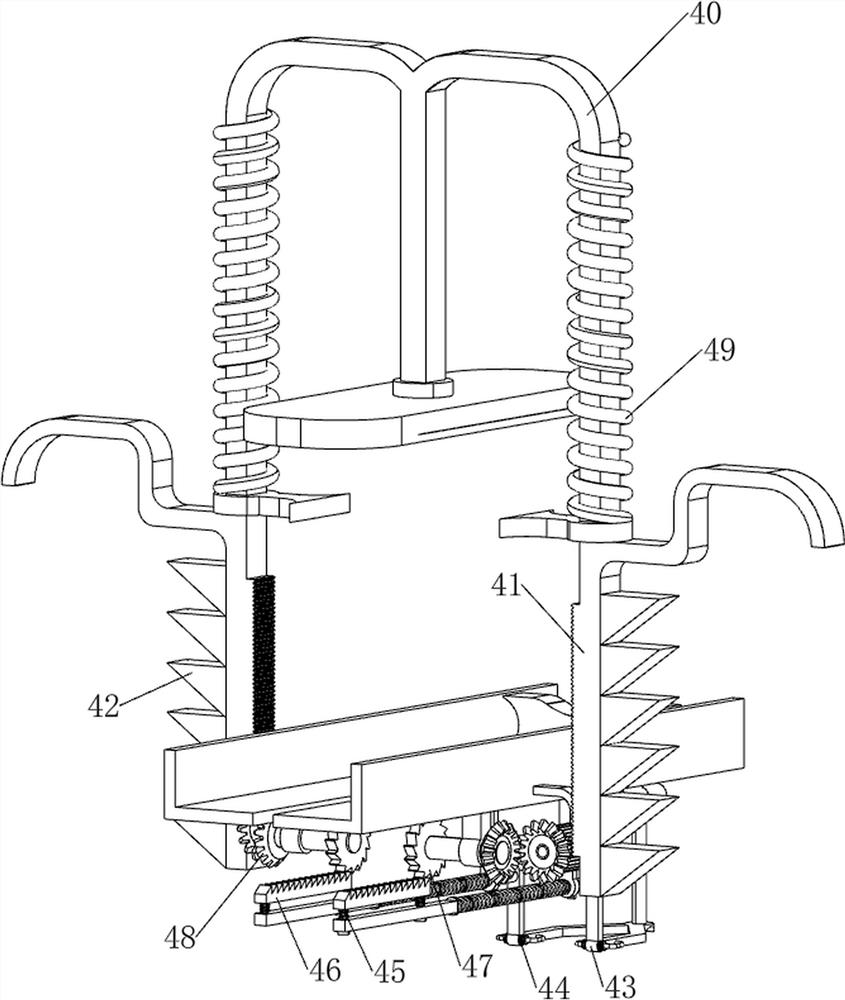

[0035] On the basis of Example 1, such as figure 1 , image 3 , Figure 4 , Figure 5 and Figure 6Shown, also comprise pressing mechanism 4, and pressing mechanism 4 comprises pressing plate 40, rack 41, first wedge block 42, first push plate 43, first torsion spring 44, second spring 45, ratchet 46 , ratchet 47, bevel gear set 48 and the 3rd spring 49, on the loading box 21 sliding type is connected with pressing plate 40, and the inner side lower part of pressing plate 40 front and rear sides all is connected with rack 41, and the outer side of pressing plate 40 front and rear sides The lower part is connected with a plurality of first wedge-shaped blocks 42, and the left side of the push rod 24 is symmetrically connected with two first push plates 43, and the first torsion spring is connected between the first push plate 43 and the push rod 24. 44. The lower part of the charging box 21 is slidingly connected with two sliding rods symmetrically front and back. The slidi...

Embodiment 3

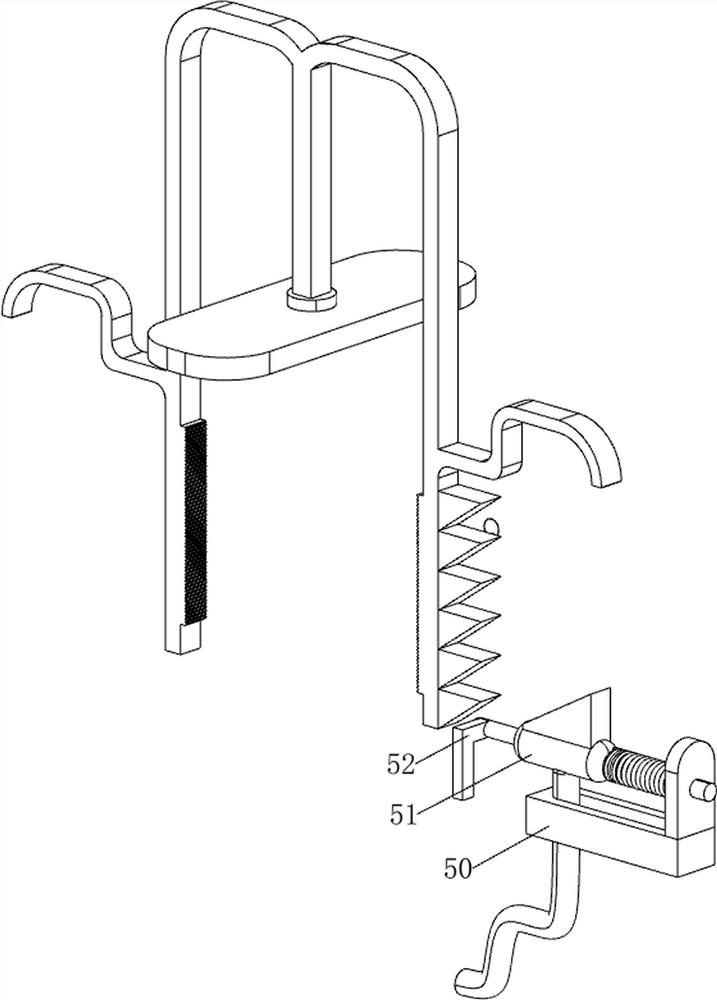

[0039] On the basis of Example 2, such as figure 1 and Figure 7 As shown, a side pull mechanism 6 is also included, and the side pull mechanism 6 includes a driving lever 60, a sixth spring 61, a seventh spring 62, a material holding frame 63, a second slide rail 64, a third wedge block 65 and an eighth spring. Spring 66, lever 60 is connected to the outer surface of splint 31, and lever 60 is in contact with slide bar 52, and the sixth spring 61 is connected between splint 31 and guide rail 32, and the four supporting frames 30 are slidably connected with filling material. Frame 63, four seventh springs 62 are connected between the material holding frame 63 and the base 1, a second slide rail 64 is connected between the support frames 30 on the left and right sides, and a third slide rail 64 is slidingly connected to the second slide rail 64. The wedge block 65 and the third wedge block 65 cooperate with the material holding frame 63 , and the eighth spring 66 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com