Composite wear-resistant carbon fiber hoisting rope

A hoisting rope and carbon fiber technology, used in cranes, cable cranes, hoisting devices, etc., can solve the problems of increasing construction risk, inconvenient quick connection, and easy to break off, so as to reduce construction risk and facilitate rapid The effect of connecting and preventing detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

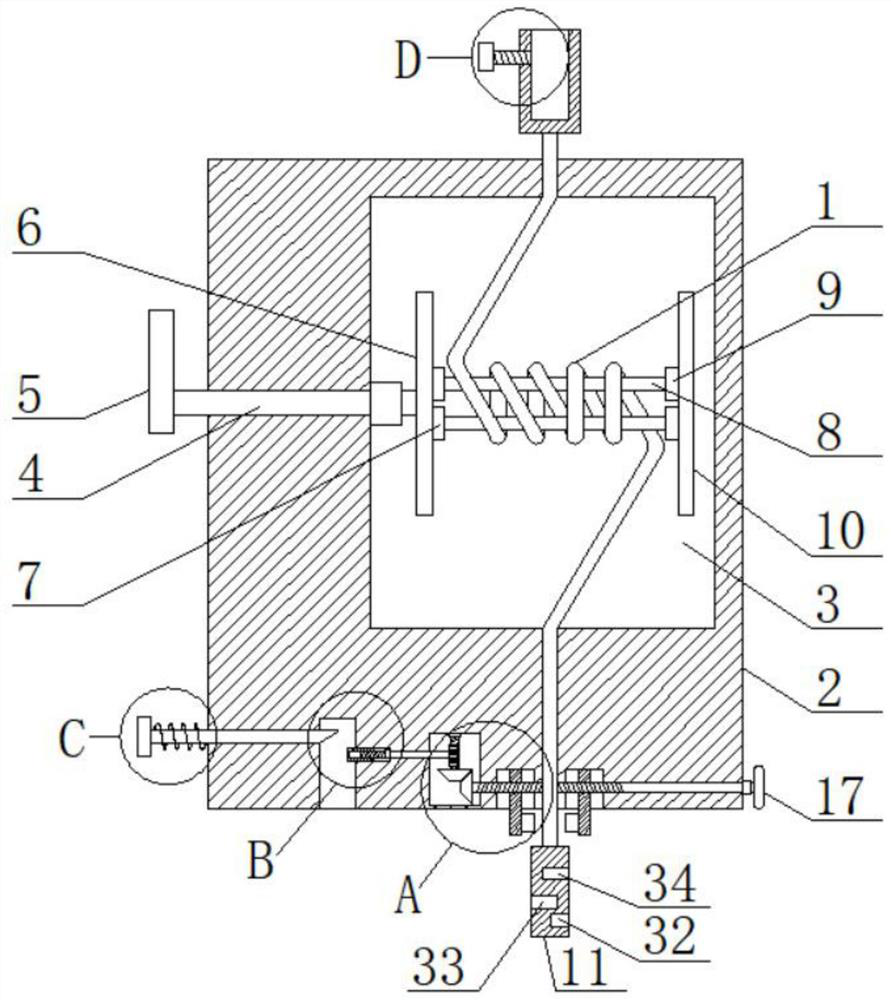

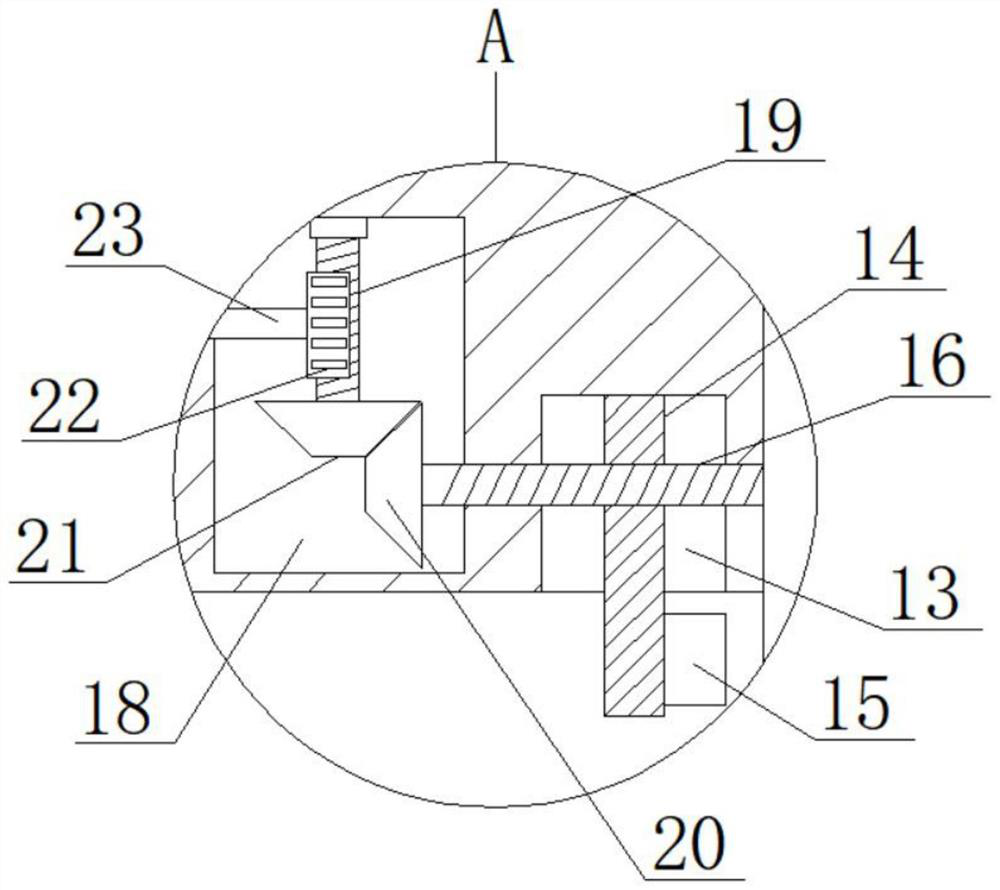

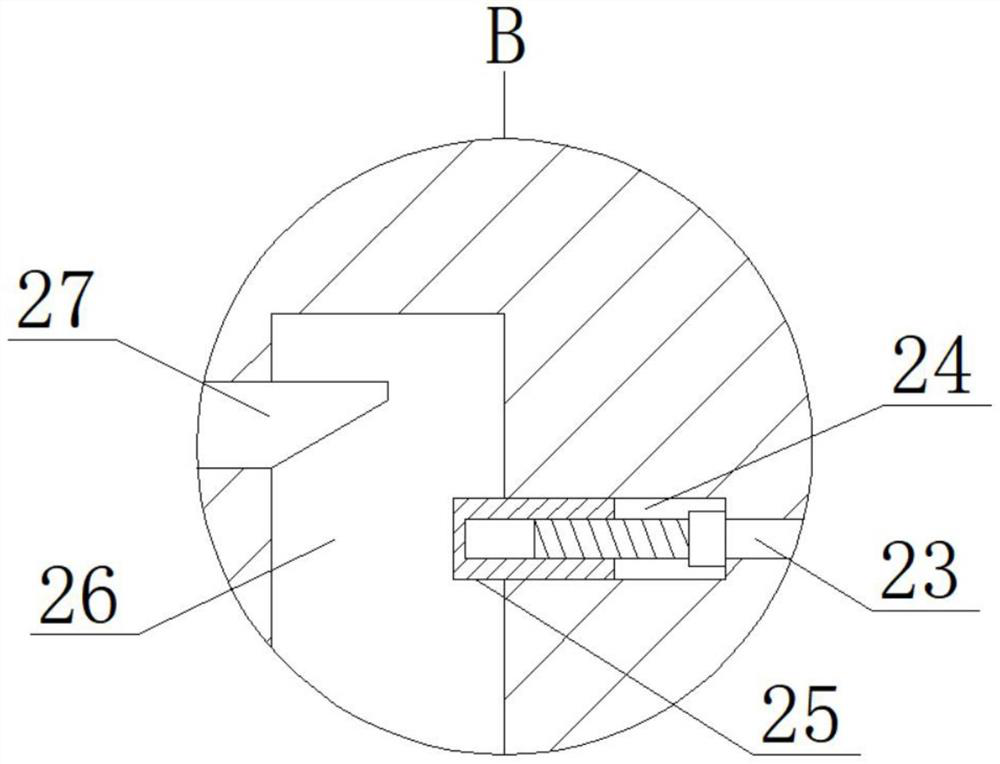

[0027] refer to Figure 1-5 , a composite wear-resistant carbon fiber lifting rope, including a carbon fiber lifting rope body 1, a storage box 2 is set on the outside of the carbon fiber lifting rope body 1, a storage cavity 3 is opened in the storage box 2, and the top inner wall of the storage cavity 3 and the inner wall of the bottom are provided with a first sliding hole, the inner walls of the two first sliding holes are slidingly connected with the outside of the carbon fiber lifting rope body 1, and one side of the storage box 2 is provided with a first through hole, the first through hole and The storage cavity 3 is connected, and the first rotating shaft 4 is installed in the first through hole. One end of the first rotating shaft 4 is fixedly connected to the rocker 5. The storage cavity 3 is provided with a winding mechanism. The two ends of the carbon fiber lifting rope body 1 The ends are respectively fixedly connected with a first connecting block 11 and a secon...

Embodiment 2

[0036] refer to Figure 1-5 , a composite wear-resistant carbon fiber lifting rope, including a carbon fiber lifting rope body 1, a storage box 2 is set on the outside of the carbon fiber lifting rope body 1, a storage cavity 3 is opened in the storage box 2, and the top inner wall of the storage cavity 3 and the inner wall of the bottom are provided with a first sliding hole, the inner walls of the two first sliding holes are slidingly connected with the outside of the carbon fiber lifting rope body 1, and one side of the storage box 2 is provided with a first through hole, the first through hole and The storage cavity 3 is connected, and the first rotating shaft 4 is installed in the first through hole. One end of the first rotating shaft 4 is fixedly connected to the rocker 5 by welding. The storage cavity 3 is provided with a winding mechanism. The carbon fiber lifting rope body 1 The first connecting block 11 and the second connecting block 12 are respectively fixedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com