Coal retaining structure of mine conveyor

A technology of loader and mine, which is used in earth-moving drilling, transportation and packaging, underground transportation, etc., to achieve the effect of light and fast bolt connection, simple structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

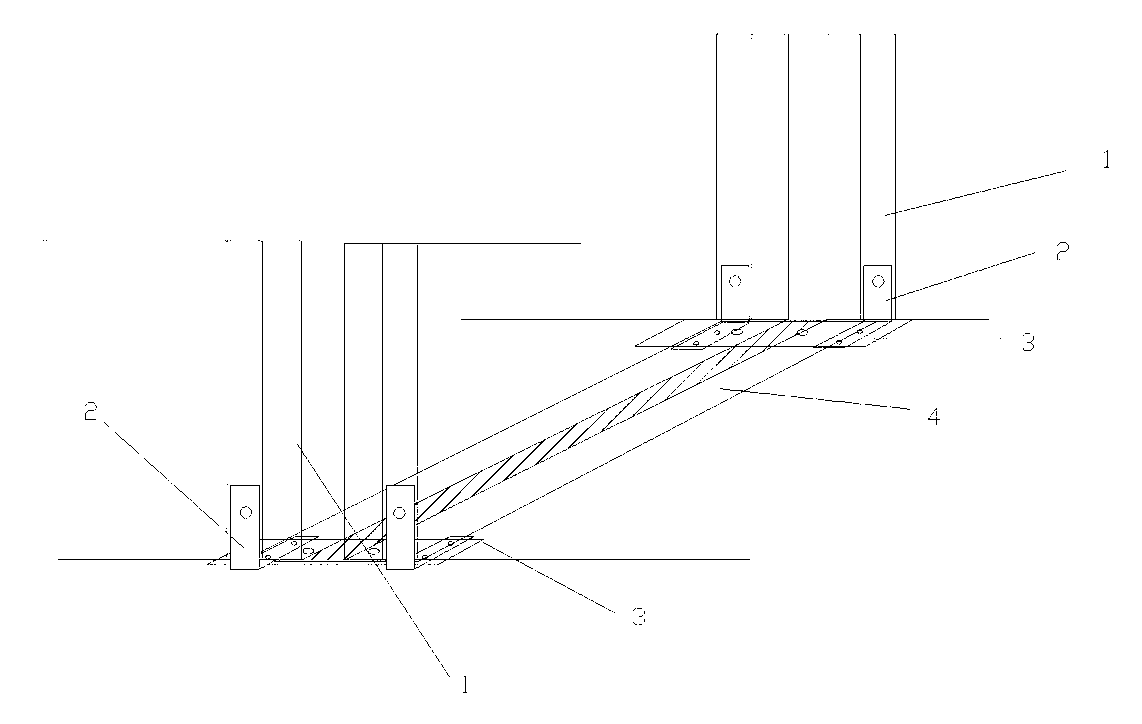

[0009] see figure 1 , the present invention arranges base plate 4 on the chute bottom plate of transfer machine 1, the two sides of base plate 4 are respectively connected with hoop 2 by bolts, the other side of two hoops 2 is connected with transfer machine 1 by bolts, two hoops Lining plates 3 are respectively arranged between 2 and the base plate 4 .

[0010] Use process: stick the bottom plate 4 to the bottom plate of the chute of the transfer machine 1, press the liner 3 tightly on the bottom plate 2, press the liner 3 through the hoop 2, connect the transfer machine 1 and the hoop 2 with the bolt 5, pass The hoop 2 and the bolts press the liner 3 onto the bottom plate 4, so that the bottom plate 4 is close to the bottom plate of the chute of the transfer machine 1. After assembly, the bolts are connected and fastened, so that the coal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com