Mig/mag welding torch body, wig welding torch body, mig/mag welding torch handle, and mig/mag welding torch comprising such a mig/mag welding torch body and mig/mag welding torch handle

A welding torch, body technology, applied in MIG/MAG welding torch body, TIG welding torch body, MIG/MAG welding torch handle and MIG/MAG including this MIG/MAG welding torch body and MIG/MAG welding torch handle In the field of welding torches, it can solve problems such as increasing production and acquisition costs, increasing production workload, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

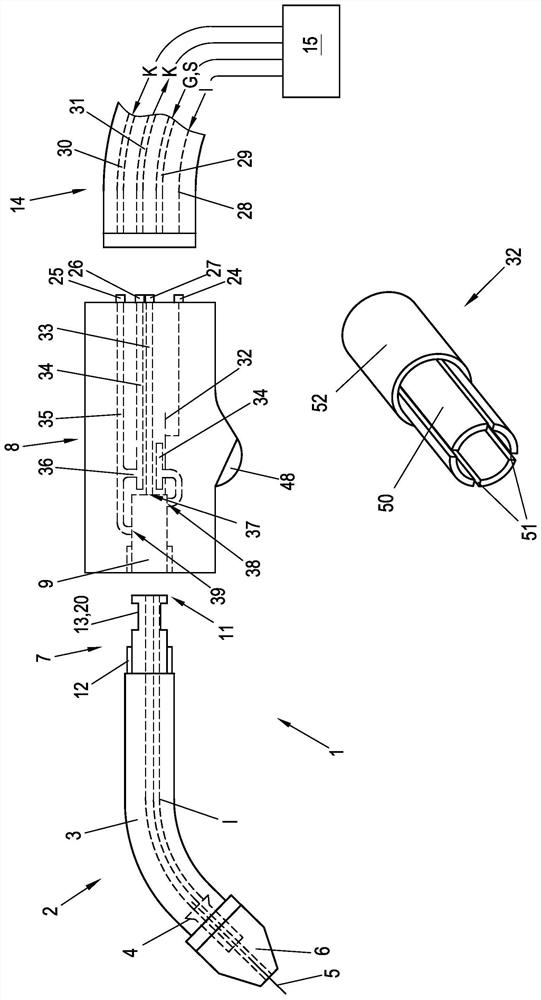

[0037] figure 1 A schematic diagram of a MIG / MAG torch 1 is shown. The MIG / MAG torch 1 is composed of a MIG / MAG torch body 2 and a MIG / MAG torch handle 8 . The MIG / MAG torch body 2 may be connected to the MIG / MAG torch handle 8 in a detachable, preferably tool-free, detachable manner. The MIG / MAG torch handle 8 is in turn connected to a corresponding hose set 14, or to a line and a hose running in the hose set 14, respectively.

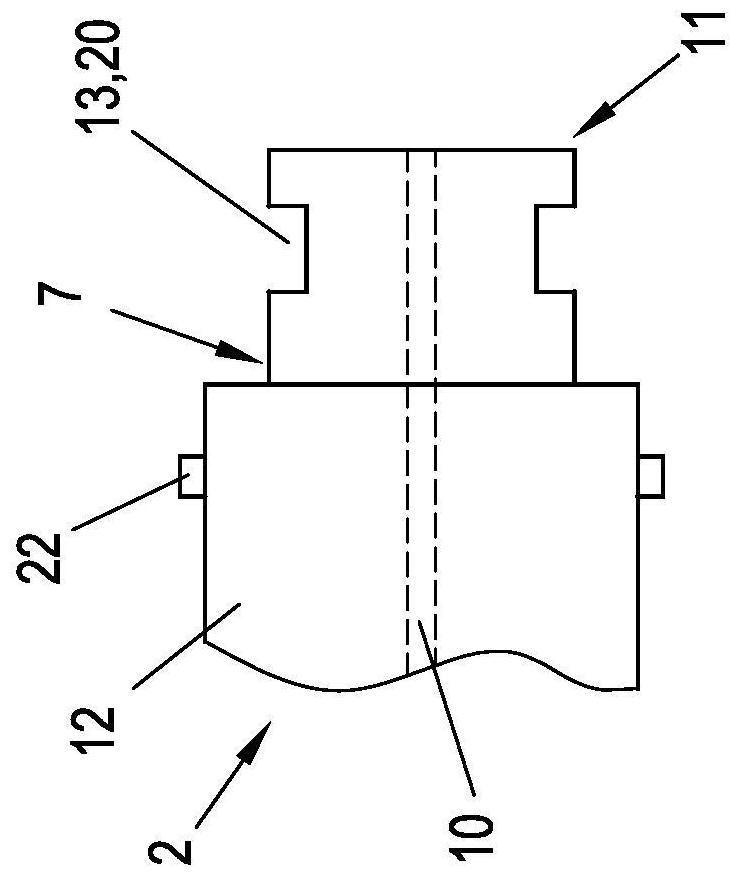

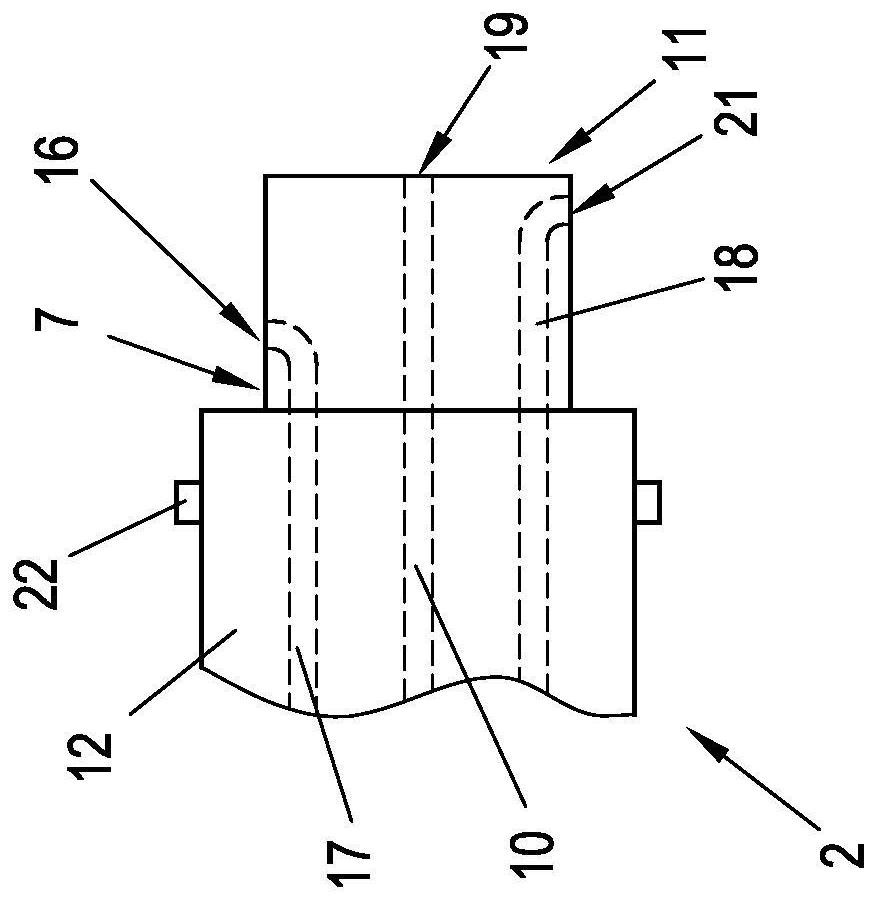

[0038] The MIG / MAG torch body 2 of the MIG / MAG torch 1 comprises a so-called elbow 3, a contact nozzle 4 for contacting and guiding a consumable welding wire 5, a gas nozzle 6 and a substantially cylindrical plug element 7, the plug Element 7 is arranged at elbow 3 for detachable connection to a corresponding receiving part 9 of MIG / MAG torch handle 8 . A gas channel 10 for guiding shielding gas G to the gas nozzle 6 runs in the plug element 7 of the MIG / MAG torch body 2 . The gas channel 10 is also simultaneously formed for guiding the consumable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com