Pervious concrete, and preparation method and application thereof

A technology of permeable concrete and cement, applied in the field of civil engineering concrete, can solve the problems of not paying attention to the tensile performance and frost resistance of concrete, and achieve the effects of improving water permeability, prolonging service life, and improving compressive strength and tensile performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

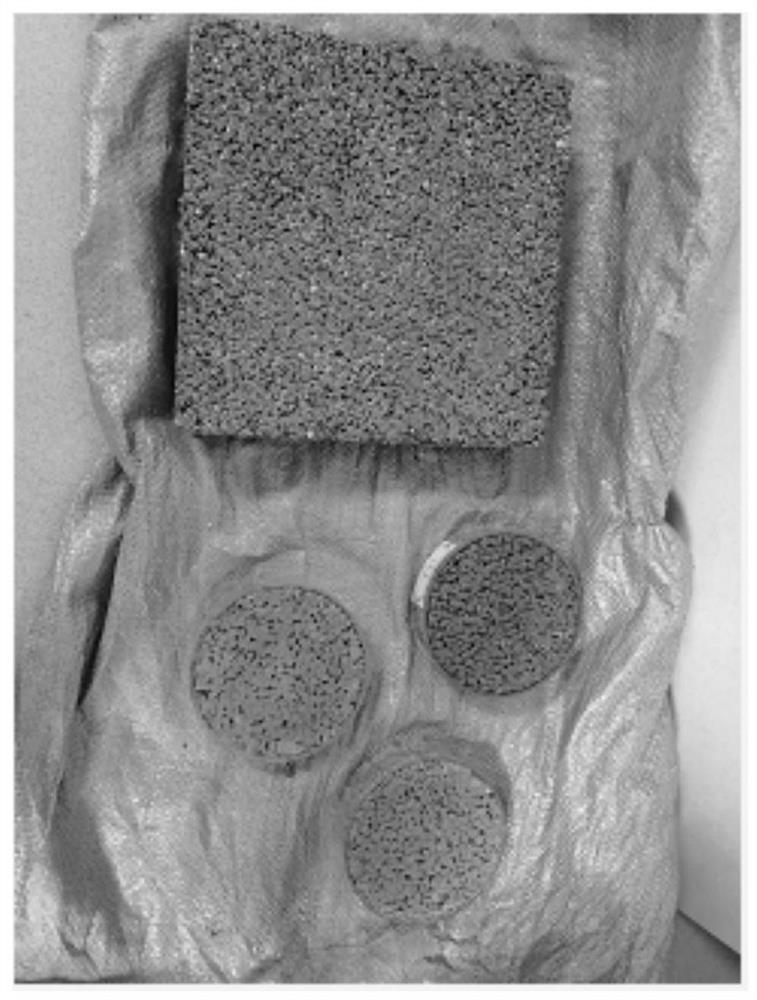

Image

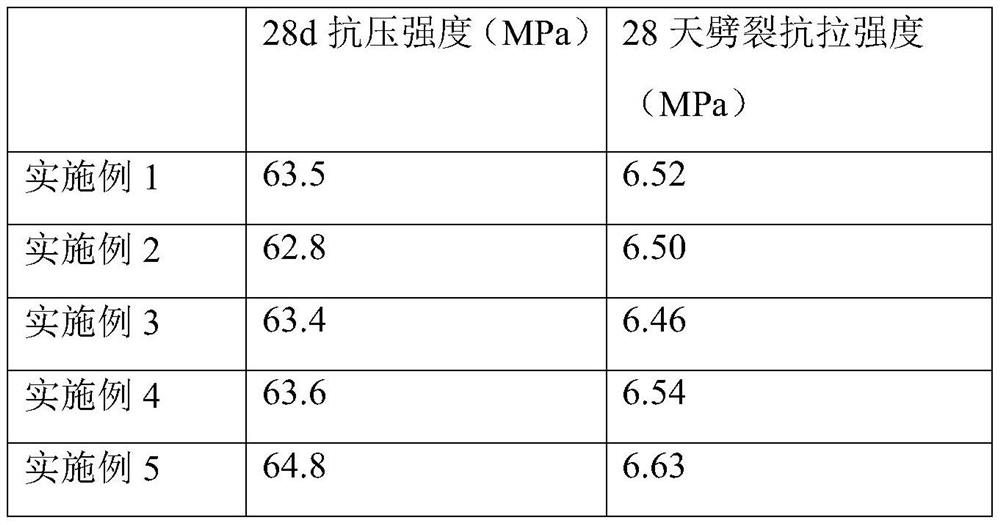

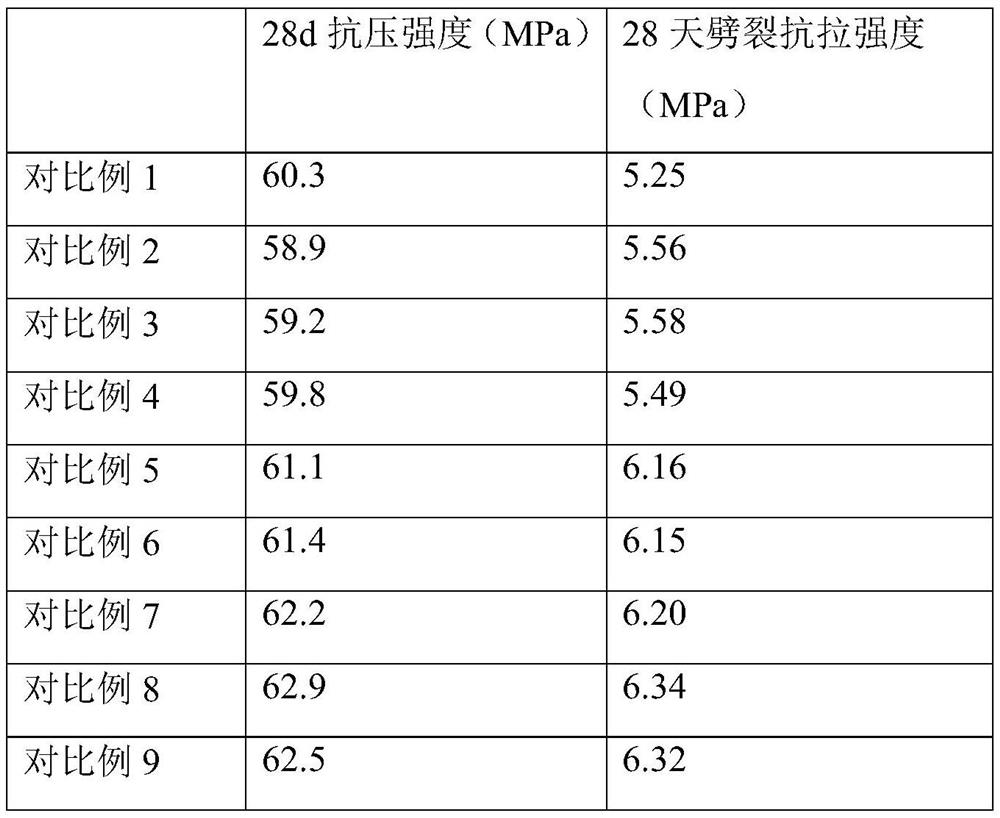

Examples

Embodiment 1

[0045] Embodiment 1 A kind of permeable concrete

[0046]It includes the following components in parts by weight: 60 parts of cement, 150 parts of stones, 4 parts of bamboo pulp fiber, 1 part of bagasse fiber, 1 part of water reducing agent, 5 parts of vinyl acetate resin, 2 parts of polymethyl acrylate and 40 parts of water.

[0047] The particle size of the stone is 15-30mm and 5-10mm, and the ratio of the two is 1:3;

[0048] Polymethyl acrylate has a degree of polymerization of 5.

[0049] The preparation method of described permeable concrete comprises the following steps:

[0050] (1) Add cement to a cement mixer and stir, then add water, water reducer, vinyl acetate resin and polymethylacrylate while stirring, and mix well to obtain premix 1;

[0051] (2) Add the stone and the reinforcing agent into the gravel mixer and stir, and after stirring evenly, the premix 2 is obtained;

[0052] (3) Add premix 1 and premix 2 into a concrete mixer and stir, and after stirring...

Embodiment 2

[0053] Embodiment 2 A kind of permeable concrete

[0054] Include the following components in parts by weight: 100 parts of cement, 250 parts of stones, 12.5 parts of bamboo pulp fiber, 2.5 parts of bagasse fiber, 10 parts of water reducing agent, 10 parts of vinyl acetate resin, 8 parts of polymethyl acrylate and 60 parts of water.

[0055] The particle size of the stone is 15-30mm and 5-10mm, and the ratio of the two is 1:5;

[0056] The degree of polymerization of polymethyl acrylate was 10.

[0057] The preparation method of described permeable concrete comprises the following steps:

[0058] (1) Add cement to a cement mixer and stir, then add water, water reducer, vinyl acetate resin and polymethylacrylate while stirring, and mix well to obtain premix 1;

[0059] (2) Add the stone and the reinforcing agent into the gravel mixer and stir, and after stirring evenly, the premix 2 is obtained;

[0060] (3) Add premix 1 and premix 2 into a concrete mixer and stir, and afte...

Embodiment 3

[0061] Embodiment 3 A kind of permeable concrete

[0062] It includes the following components in parts by weight: 70 parts of cement, 200 parts of stones, 8 parts of bamboo pulp fiber, 2 parts of bagasse fiber, 2 parts of water reducing agent, 6 parts of vinyl acetate resin, 3 parts of polymethyl acrylate and 50 parts of water.

[0063] The particle size of the stone is 15-30mm and 5-10mm, and the ratio of the two is 1:3.5;

[0064] Polymethyl acrylate has a degree of polymerization of 6.

[0065] The preparation method of described permeable concrete comprises the following steps:

[0066] (1) Add cement to a cement mixer and stir, then add water, water reducer, vinyl acetate resin and polymethylacrylate while stirring, and mix well to obtain premix 1;

[0067] (2) Add the stone and the reinforcing agent into the gravel mixer and stir, and after stirring evenly, the premix 2 is obtained;

[0068] (3) Add premix 1 and premix 2 into a concrete mixer and stir, and after sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com