Light, thin and soft single-sided weft-knitted fabric with differential moisture conductivity

A knitted fabric and differentiated technology, applied in the field of single-sided weft knitted fabrics and knitted fabrics, can solve the problems of hard feeling, oppression, poor washing resistance, etc., achieve differential moisture conductivity, reduce wet stickiness sense, slowing down the effect of horizontal diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

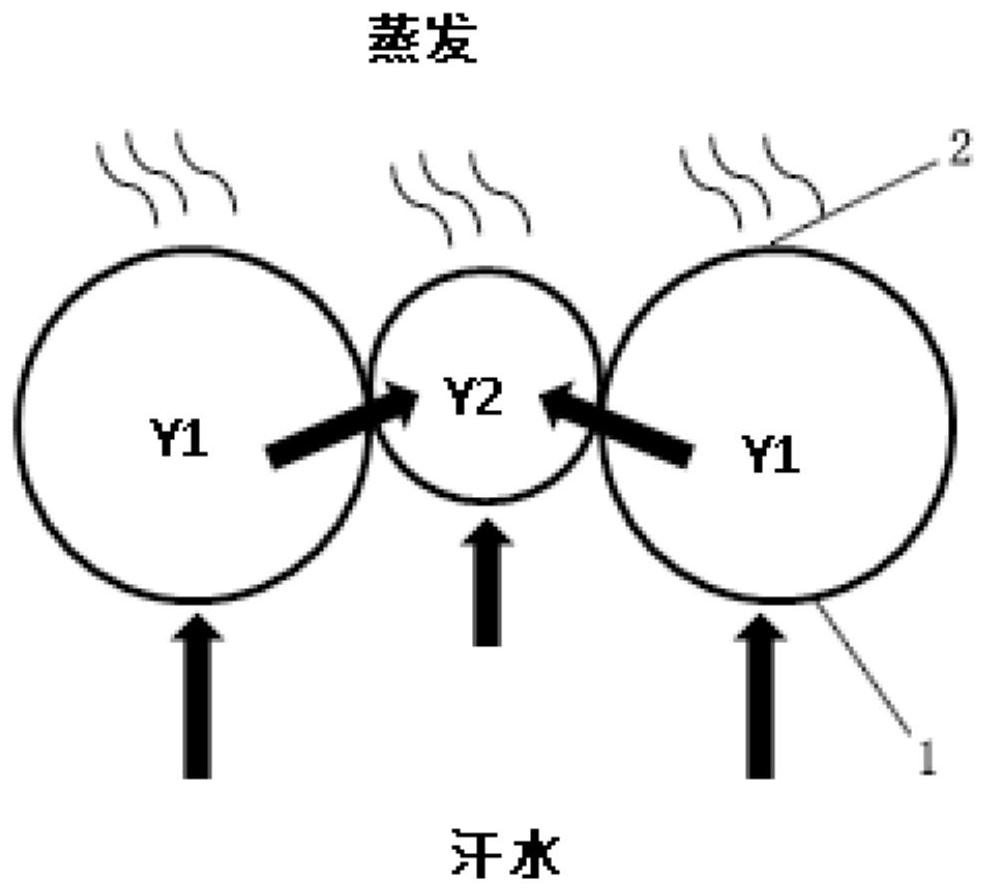

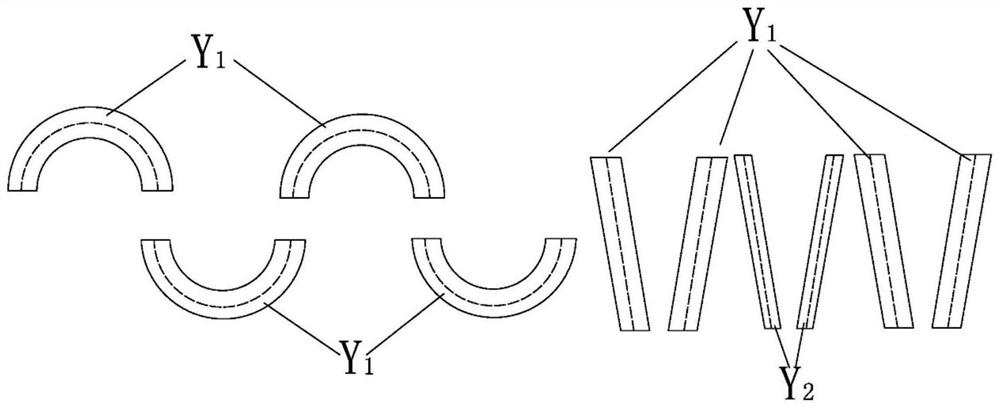

[0052] first yarn Y 1 Common C-section polyester, PES 80D / 144F; second yarn Y 2 Use ordinary round section polyester, PES 30D / 24F. The two yarns are interwoven to form the body of the fabric, and form a weft-knitted single-sided plain weave. The fabric body has a garment surface and a skin-fitting surface, the garment surface is composed of a loop and a tuck structure, and the first yarn Y 1 and the second yarn Y 2 The weave forms the garment face. The skin-adhering surface is composed of loops and tucks or float structures. Among them, the second yarn Y 2 Knitting on the skin facing to form a non-loop knitting unit; first yarn Y 1 Exposed on the skin-adhering surface, forming a geometrically discontinuous raised area. In a unit loop organization, there are two first yarns Y 1 and a second yarn Y 2 composition, m=2, n=1.

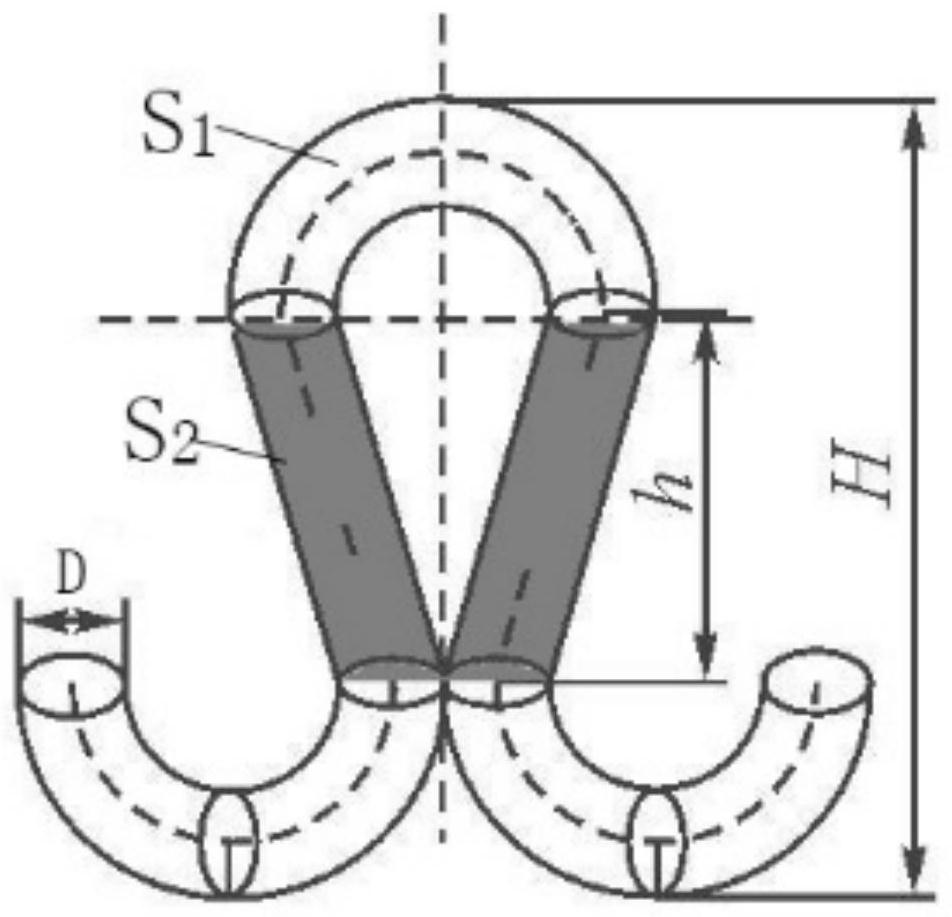

[0053] like Figure 1-3 As shown, in this embodiment, the coverage area S of the skin facing yarn B =2S 1Y1 +S 2y2 ×W; Covering area S of the ...

Embodiment 2

[0069] On the basis of Example 1, 150D / 288F polyester is adopted as the first yarn Y 1 and 40D / 36F polypropylene as the second yarn Y 2 . The two yarns are interlaced to form the main body of the fabric, which is then piled. Among them, the second yarn Y2 A yarn that is a non-loop knitting unit of the skin facing; a first yarn Y 1 Exposed on the skin-adhering surface, it is a geometrically discontinuous raised area. The garment surface is a jacquard structure, and the skin surface has a fluffy area. In a unit loop organization, there are two first yarns Y 1 and a second yarn Y 2 composition, m=2, n=1.

[0070] In this embodiment, the coverage area S of the skin-facing yarn B =2S 1Y1 +S 2y2 ×W; Covering area S of the yarn on the garment surface of the knitted fabric F =2S 2y1 +S 2y2 .

[0071] first yarn Y 1 (150D / 288F) Polyester monofilament equivalent radius is:

[0072]

[0073] D. Y1 =2×3.16=6.32(μm)

[0074] Similarly, we calculate the second yarn Y 2 ...

Embodiment 3

[0086] On the basis of embodiment 1, adopt the first yarn Y 1 : Polyester (PES 80D / 144F) and second yarn Y 2 : Nylon 66 (50D / 48F), the two yarns are interwoven to form the body of the fabric, and form a weft-knitted single-sided fabric. Among them, the second yarn Y 2 A yarn that is a non-loop knitting unit of the skin facing; a first yarn Y 1 Exposed on the skin-adhering surface, it is a geometrically discontinuous raised area. In a unit loop organization, there are four first yarns Y 1 and three second yarns Y 2 composition, m=4, n=3.

[0087] In this embodiment, the coverage area S of the skin-facing yarn B = 4S 1Y1 ; The covered area S of the yarn on the garment surface of the knitted fabric F = 4S 2y1 +3S 2y2 ×W.

[0088] first yarn Y 1 (80D / 144F) Polyester monofilament equivalent radius is:

[0089]

[0090] D. Y1 =2×3.80=7.6(μm)

[0091] Similarly, we calculate the second yarn Y 2 (50D / 48F) Nylon 66 monofilament equivalent radius is:

[0092]

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com