Double-face basic structure differential moisture-conducting fabric

A basic structure and differentiated technology, applied in fabric surface trimming, roughening, textiles and papermaking, etc., can solve problems such as unsatisfactory one-way moisture guide effect, narrow range of suitable fabrics, poor washing resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

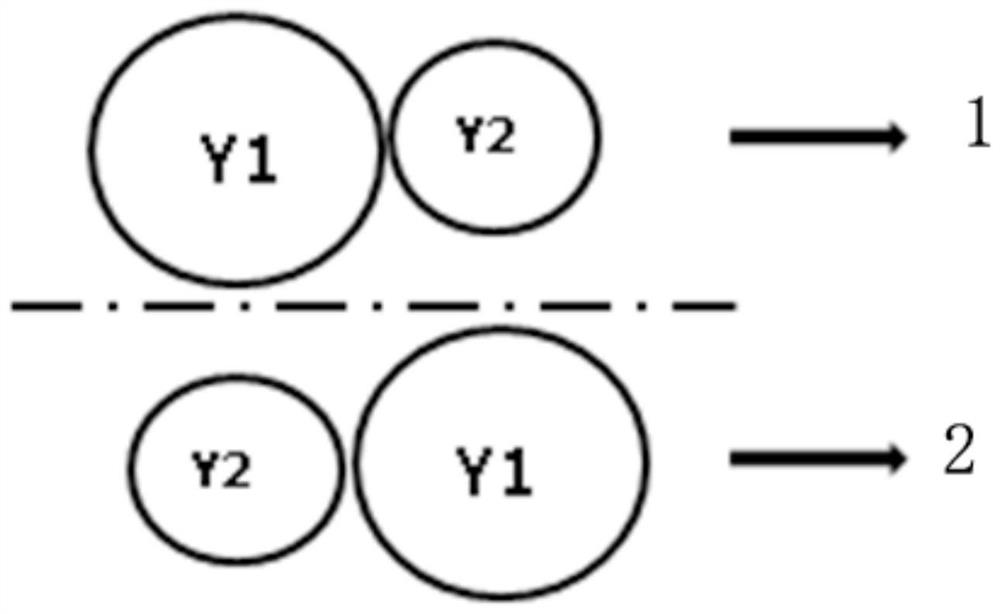

[0043] first yarn Y 1 Using mechanical elastic polyester 75D / 48F, the second yarn Y 2 Polyester 40D / 72F is used, among which, the first yarn Y 1 diameter D 1 with the second yarn Y 2 diameter D 2 Ratio ≥ 1.2, the first yarn Y 1 Water conductivity of LP 1 with the second yarn Y 2 Water conductivity of LP 2 Ratio1 and n of the second yarn Y 2 A unit loop structure woven into the fabric body is arranged in an adjacent or alternate manner, m=1, n=1 in Example 1; and the first yarn Y 1 or the second yarn Y 2 Any one of the yarns is distributed in a ratio of 1:1 on the clothing side 1 and the skin-fitting side 2 of the fabric body.

[0044] In this example, a plane made of the yarn was formed by tightly winding the yarn on a microscope slide, water was dropped on the plane by a contact angle measuring instrument, and the contact angle θ thereof was measured. first yarn Y 1 (model is round PES 75D / 48F) contact angle θ 1 is 63°, the second yarn Y 2 (model is round PES 40...

Embodiment 2

[0074] On the basis of Example 1, the converted material is used to weave a polyester and nylon knitted fabric with a double-sided structure.

[0075] Use ordinary round polyester 75D / 36F as the first yarn Y 1 and Nylon 66 (50D / 48F) as the second yarn Y 2 . The two yarns are interlaced to form the main body of the fabric, which is then piled. M the first yarn Y 1 and n of the second yarn Y 2 A unit loop structure woven into the fabric body is arranged in an adjacent or alternate manner, m=1, n=1 in Example 1; and the first yarn Y 1 or the second yarn Y 2 Any one of the yarns is distributed in a ratio of 1:1 on the clothing side 1 and the skin-fitting side 2 of the fabric body.

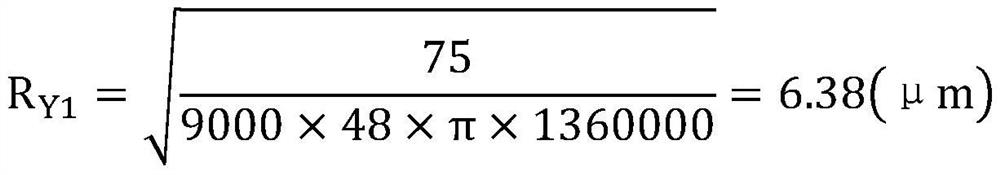

[0076] In this embodiment, the known polyester density in the industry is 1360000g / m 3 , nylon density is 1150000g / m 3 . first yarn Y 1 (75D / 36F) Polyester monofilament equivalent radius is:

[0077]

[0078] D. Y1 =2×7.36=14.72(μm)

[0079] Capillary equivalent radius r Y1 =0.227R Y1...

Embodiment 3

[0096] On the basis of embodiment 1, adopt the first yarn Y 1 : Ordinary round polyester 75D / 36F and second yarn Y 2 : Cross-section nylon yarn 70D / 68F, the two yarns are interwoven to form the fabric body, and form a weft-knitted double-sided fabric.

[0097] first yarn Y 1 (75D / 36F) Polyester monofilament equivalent radius is:

[0098]

[0099] D. Y1 =2×7.36=14.72(μm)

[0100] Capillary equivalent radius r Y1 =0.227R Y1 =1.67(μm)

[0101] It is convenient to calculate the total capillary volume of round 75D / 36F polyester single yarn

[0102]

[0103] Similarly, we calculate the second yarn Y 2 (70D / 68F) The equivalent radius of cross-section nylon monofilament is:

[0104]

[0105] D. Y2 =2×5.48=10.96(μm)

[0106] Capillary equivalent radius r Y2 =0.471R Y2 =2.58μm)

[0107] It is convenient to calculate the total capillary volume of cross-section 70D / 68F nylon single yarn

[0108]

[0109] Known first yarn Y 1 Polyester contact angle θ 1 The ang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com