Watering, curing and film covering integrated device and using method

A technology of curing film and covering film, which is applied in the processing of building materials, construction, building construction, etc., which can solve the problems of complex operation, pockmarked surface, and easy generation of air bubbles, and achieve the effect of simple operation and simple and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

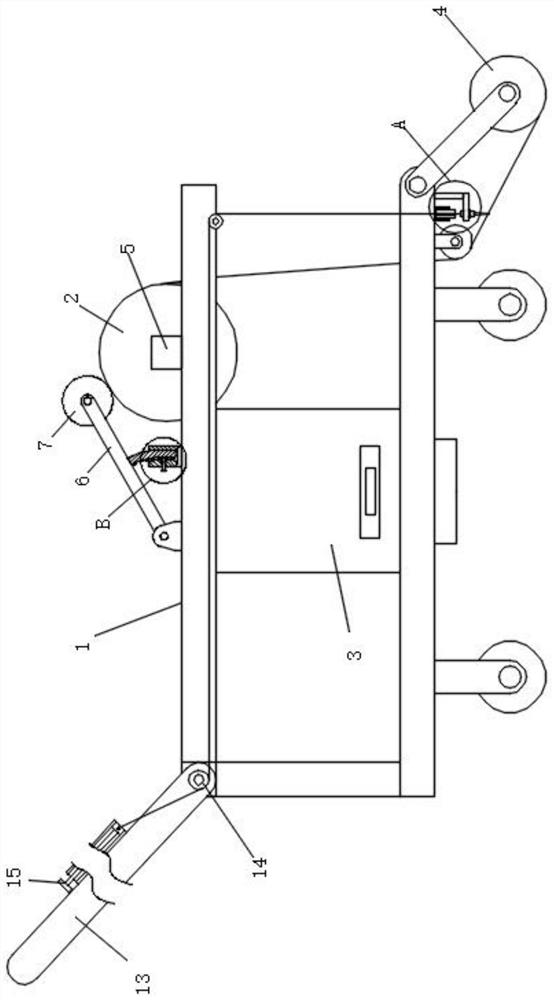

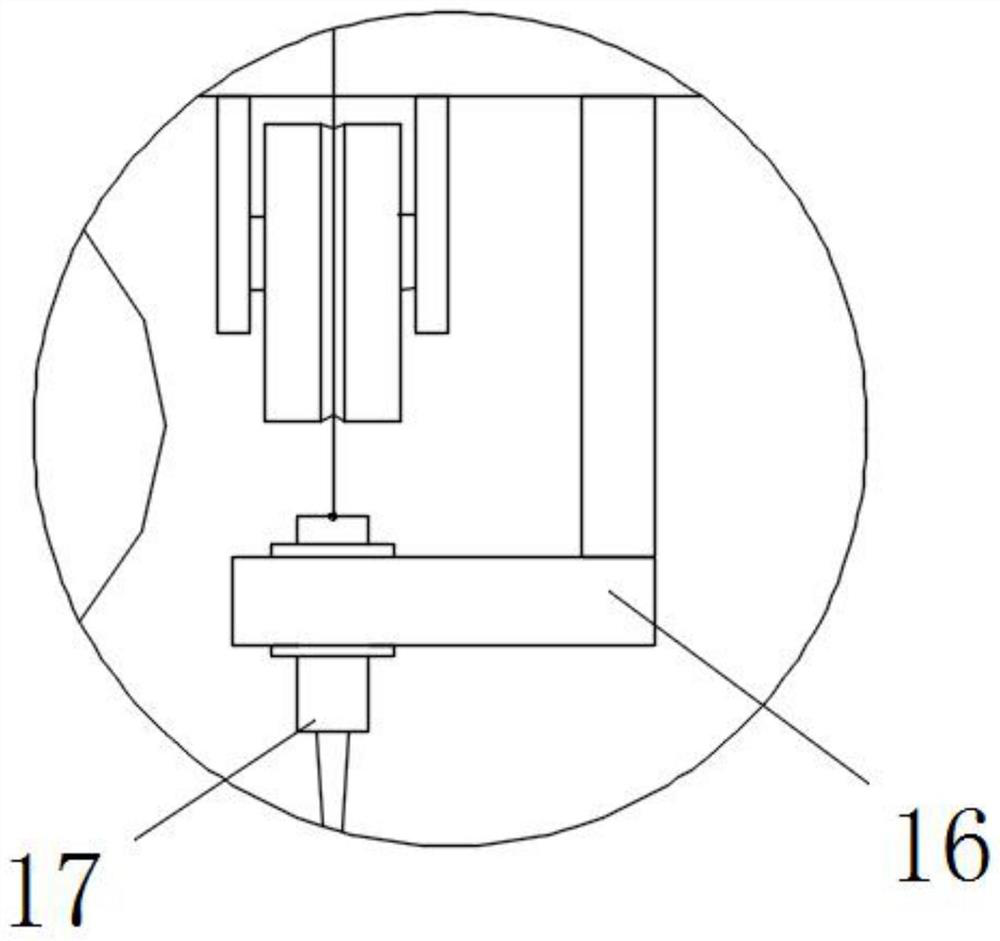

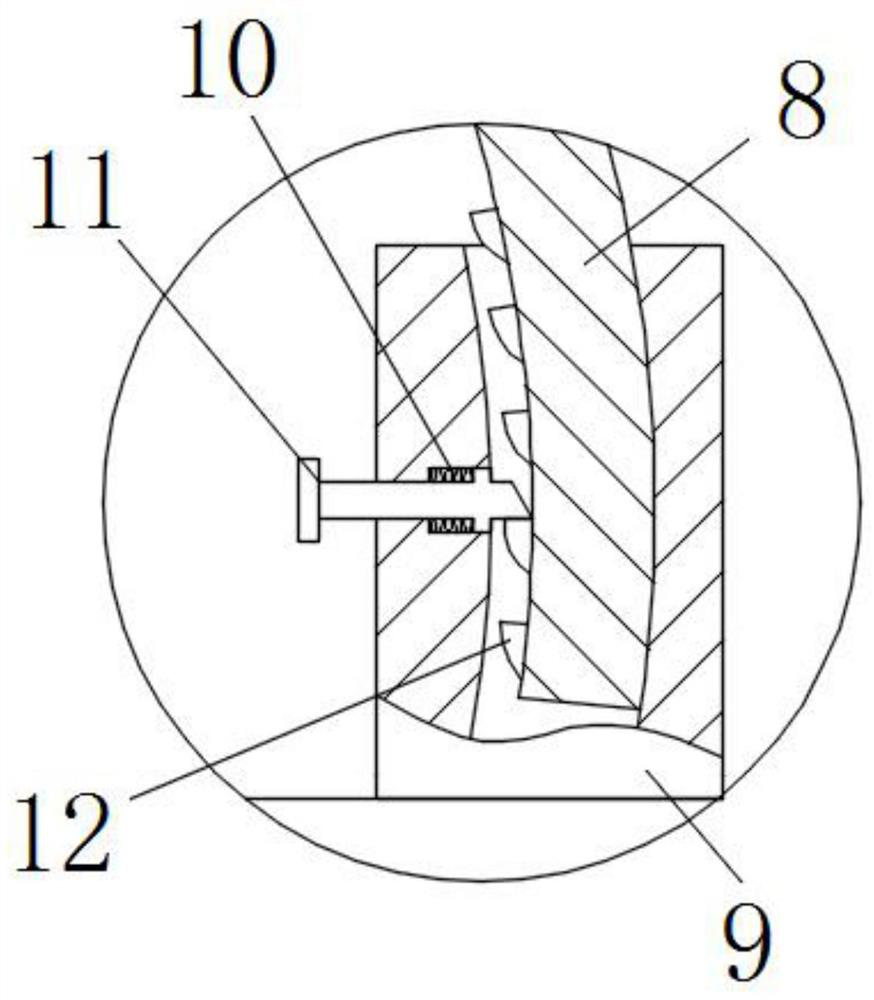

[0028] Such as Figure 1 to Figure 4 As shown, a sprinkling maintenance and coating integrated device includes a frame body 1, a coating roller 2, a sprinkler 3 and a smoothing roller 4, and a support seat 5 is installed on the left and right sides of the frame body 1, and the coating The two ends of the film roller 2 are installed on the corresponding supporting base 5 respectively, the sprinkler 3 is fixedly installed on the frame body 1 and is positioned at the front side of the curing film extracted from the film roller 2, and the smoothing roller 4 is set The rear side of the frame body 1 is used to apply pressure to maintain the membrane and discharge the gas inside. The coating roller 2 is supported by the support seat 5, and the smoothing roller 4 is used to level the concrete, and the second is to apply pressure to the drawn-out curing film on the coating roller 2, so that the curing film and the watered concrete Make a tight fit and discharge the internal air to ens...

Embodiment 2

[0033] Such as Figure 1 to Figure 4 As shown, a method for using a sprinkling maintenance film-covering integrated device comprises the following steps:

[0034] Step 1: Place the frame body 1 on the top of the concrete after preliminary leveling, push or pull the frame body 1 to move forward through the armrest 13, start the sprinkler 3, spray water to the concrete surface through the sprinkler 3, and apply the film The curing film extracted from the roller 2 passes under the pressure roller 7 and attaches to the concrete surface after watering;

[0035] Step 2: Then push or pull the frame body 1 to move forward, and the coating roller 2 will drive the coating roller 2 to rotate under the action of the curing film attached to the watered concrete, and the pressure rod 6 and the arc guide rod 8. Under the action of the limit block 12 and the limit rod 11, the coating roller 2 can only rotate to one side in the direction in which the curing film is pulled out under the action...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com