Three-dimensional micro-motion fixed measuring device for optical measured object

A measuring device and three-dimensional technology, applied in the field of measurement, can solve the problems of inaccurate measurement, human error, no technical solution, etc., and achieve the effect of avoiding human error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The invention provides a technical solution:

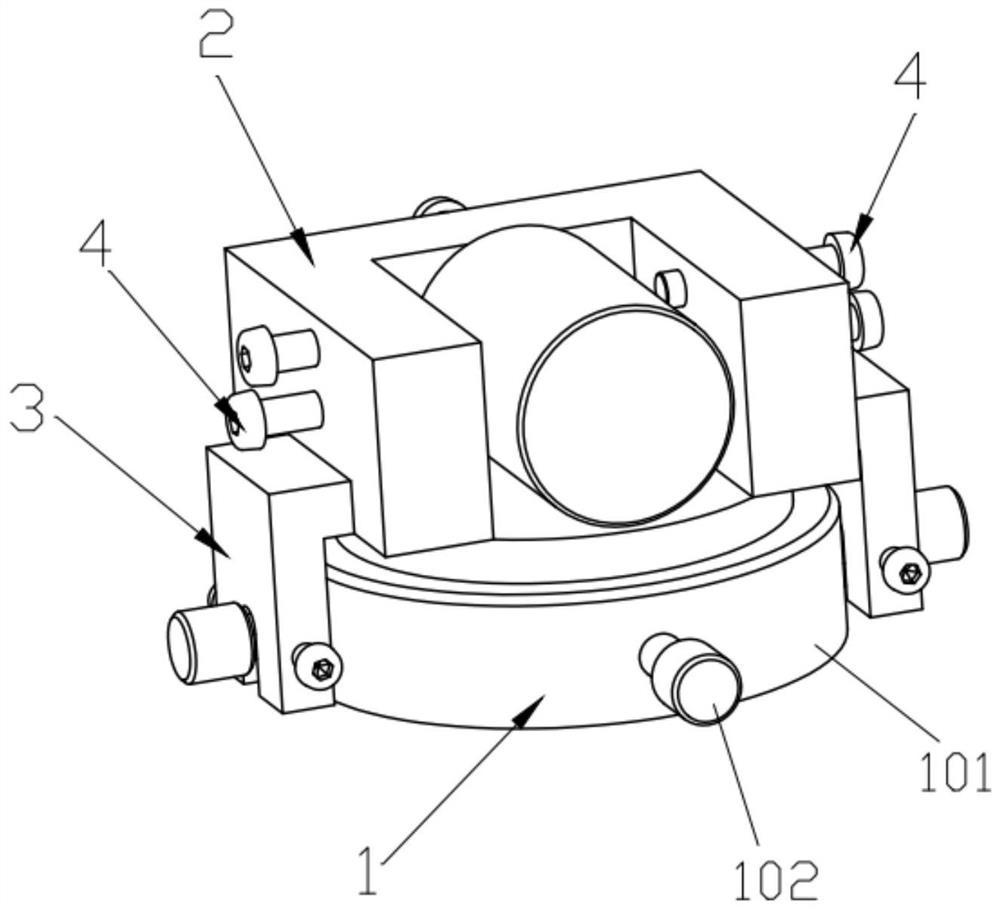

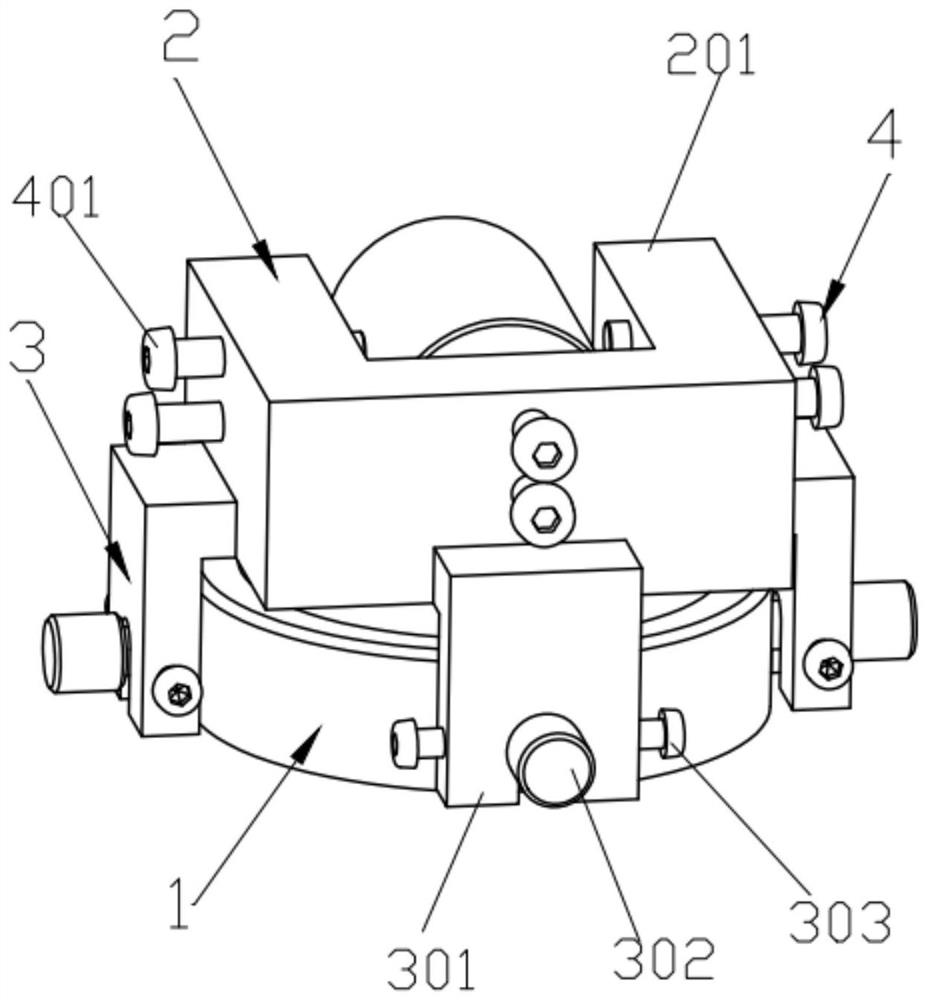

[0026] Please refer to Figure 1-2 , a three-dimensional micro-movement fixed measuring device for an optical measured object, comprising an instrument table 1, a U-shaped fixed assembly, three T-shaped fixed assemblies 3 and a fine-tuning assembly 4, the U-shaped fixed assembly is installed on the instrument On the workbench 1, the three T-shaped fixing assemblies 3 are installed on the peripheral wall of the instrument workbench 1 respectively, and the line connecting the axes of the two T-shaped fixation assemblies 3 is connected with the instrument workbench 1 Any diameter coincides with each other, the axis of the other T-shaped fixing assembly 3 is perpendicular to the line, and one of the fine-tuning assemblies 4 is installed on the three side walls of the U-shaped fixing assembly.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap