A height-adjustable planar cascade test section

A technology of cascade test and test section, which is applied in engine test, machine/structural component test, jet engine test, etc. It can solve the problems of reduced test accuracy, high labor intensity, inconvenient operation, etc., and save test The effect of preparation time, high test accuracy and simple test preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

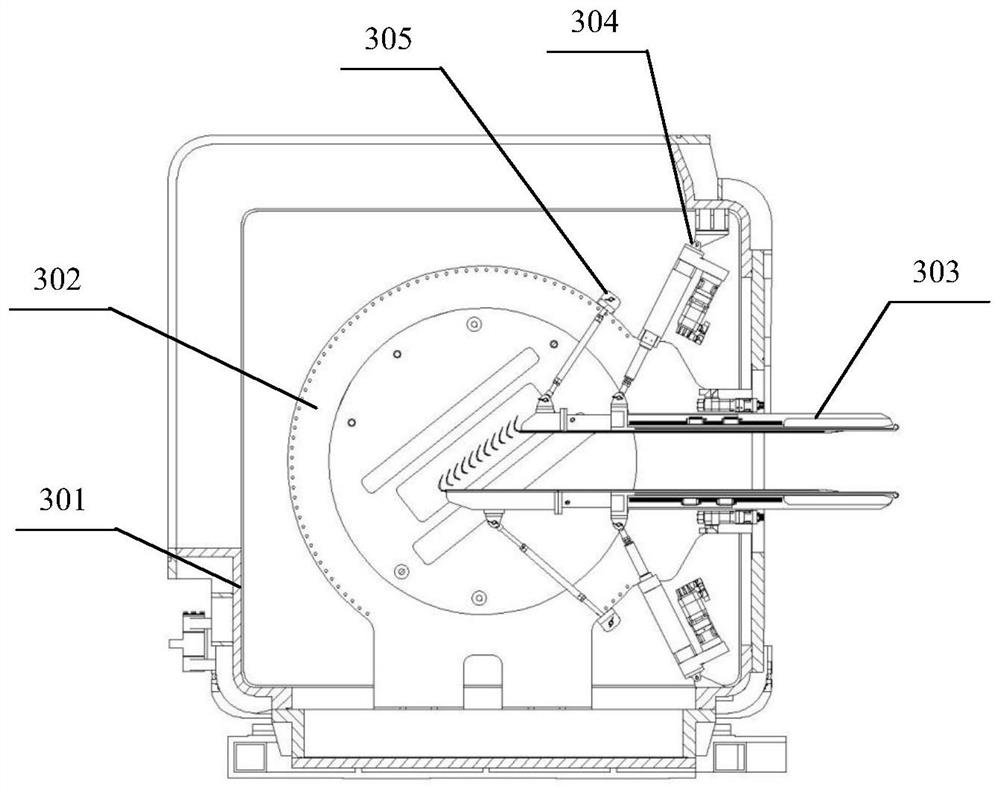

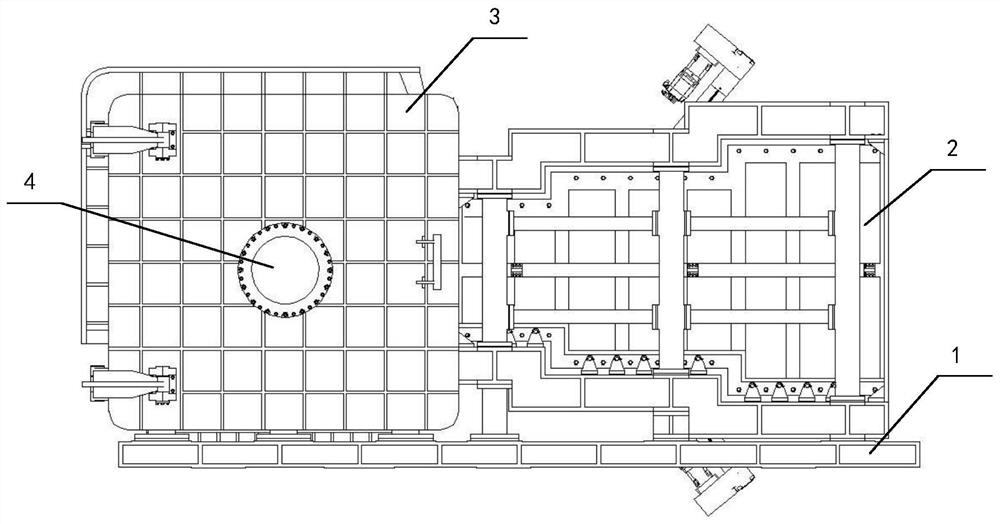

[0036] like figure 2 As shown, the height-adjustable plane cascade test section of this embodiment is installed on the installation platform 1, and the height-adjustable sonic nozzle 2 and the plane cascade test section 3 are sequentially connected along the airflow direction on the installation platform 1; A test model of a turbine cascade or a test model of a compressor cascade is installed in the cascade test section 3 , and an observation window 4 is installed in the center of the side wall of the plane cascade test section 3 .

[0037] The height-adjustable plane cascade test section of this embodiment realizes the height-adjustable sonic nozzle 2 through the height regulator in the outlet height-adjustable height sonic nozzle 2 and the angle regulator 304 of the plane cascade test section 3 The combined adjustment of the outlet height of the outlet and the height of the upper and lower wall panels of the plane cascade test section 3, the height adjustment range is 225mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com