A high-voltage electric field coupling ultrasonic treatment liquid sterilization test device and method

A high-voltage electric field and testing device technology, applied in water supply devices, disinfection, construction, etc., can solve problems such as excessive local temperature rise, changes in other liquid properties, and joint sterilization that has not been discussed in depth, and achieve the effect of improving sterilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with drawings and embodiments.

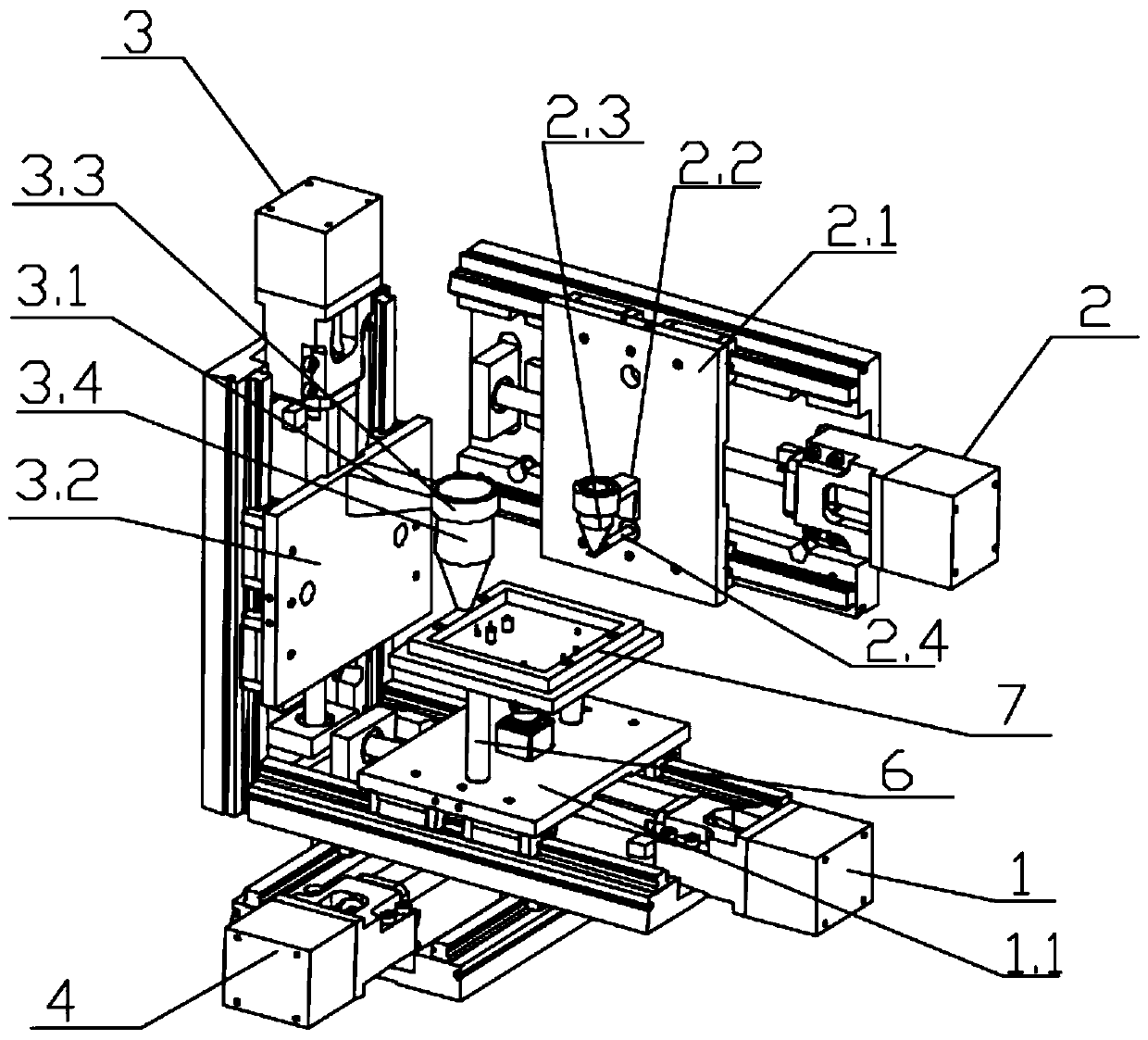

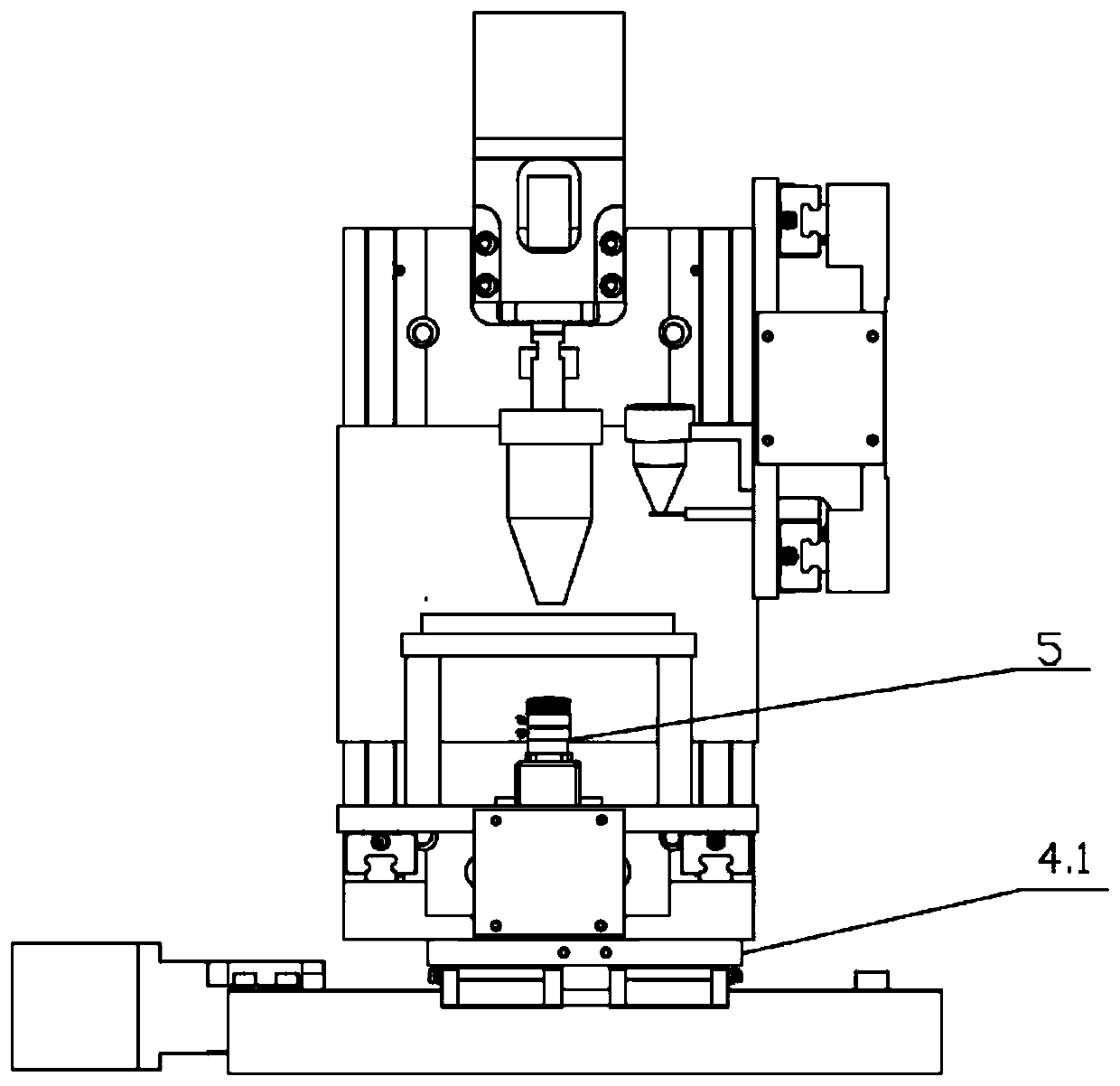

[0030] Such as figure 1 with figure 2 As shown, the specific implementation of the present invention includes a first sliding table group 1, a second sliding table group 2, a third sliding table group 3, a fourth sliding table group 4, a coupling agent assembly, an ultrasonic excitation assembly, a high-speed camera 5, and a support frame 6 and the microfluidic module 7; the microfluidic module 7 is placed on the support frame 6, the support frame 6 is fixed on the first connecting block 1.1 of the first slide group 1, and the first slide group 1 is installed on the fourth slide On the platform group 4, the first sliding platform group 1 and the fourth sliding platform group 4 are arranged vertically, so that the microfluidic module 7 can move along the horizontal plane driven by the first sliding platform group 1 and the fourth sliding platform group 4; A high-speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com