Laser processing apparatus and method for determining processing crack

A technology of laser processing and processing marks, which is applied to laser welding equipment, metal processing equipment, manufacturing tools, etc., and can solve the problem of time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

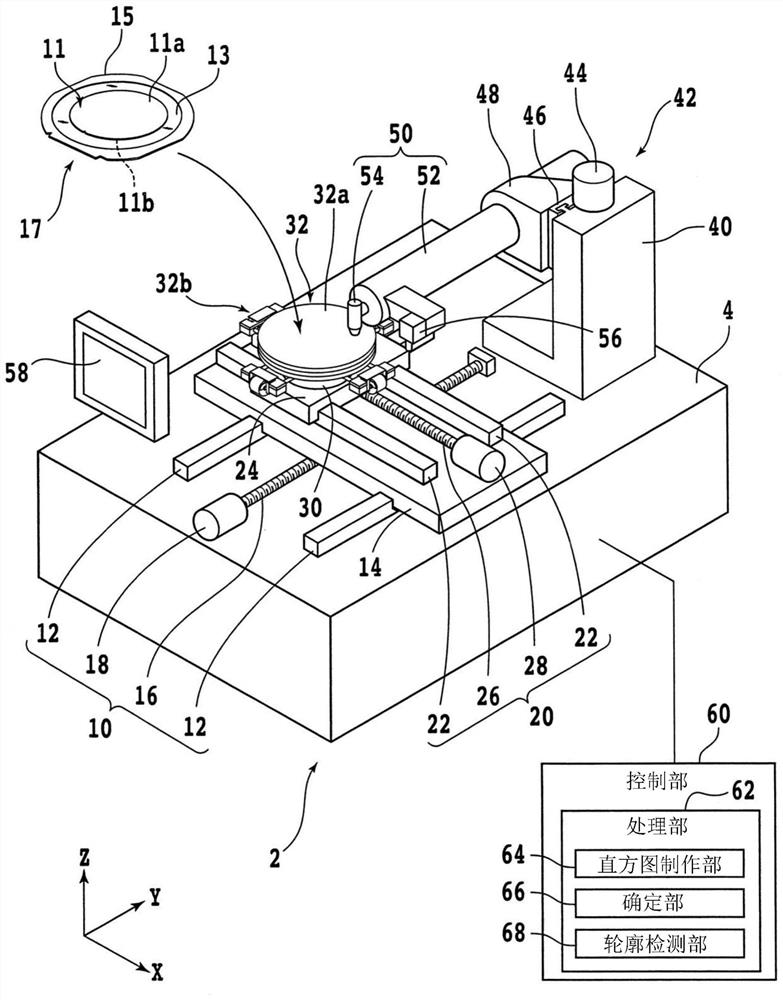

[0028] An embodiment of one embodiment of the present invention will be described with reference to the drawings. figure 1 It is a perspective view of the laser processing device 2 . In addition, in figure 1In , some components of the laser processing apparatus 2 are shown as functional blocks.

[0029] in addition, figure 1 The indicated X-axis direction (left-right direction, machining feed direction, first direction), Y-axis direction (front-back direction, index feed direction, second direction) and Z-axis direction (vertical direction, height direction) are mutually vertical.

[0030] The laser processing device 2 has a cuboid-shaped base 4 that supports each structure. A Y-axis direction moving unit 10 is provided on the upper surface of the base 4 . The Y-axis direction moving unit 10 has a pair of Y-axis guide rails 12 parallel to the Y-axis direction.

[0031] A pair of Y-axis guide rails 12 is fixed on the upper surface of the base 4 . The Y-axis moving table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com