An electric tractor fast counterweight system and its control method

A tractor and electric technology, applied in the direction of motor vehicles, tractors, vehicle parts, etc., can solve the problems of not being able to give full play to the performance of the whole machine, increasing the energy consumption of the tractor, and not being able to adjust the size of the counterweight, so as to improve the handling stability, Avoid the influence of dust and impurities, and prevent the effect of moving from side to side

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

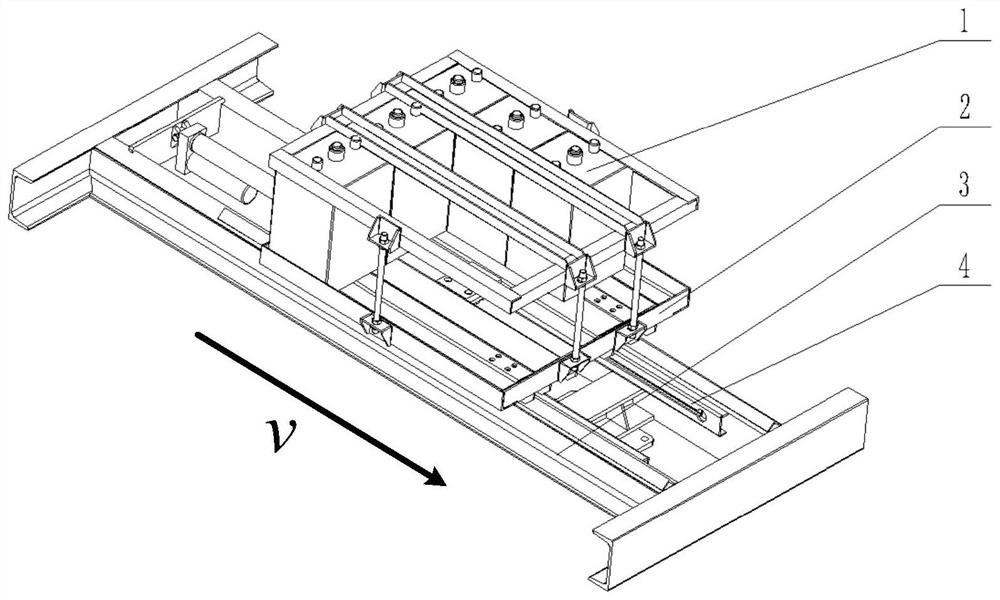

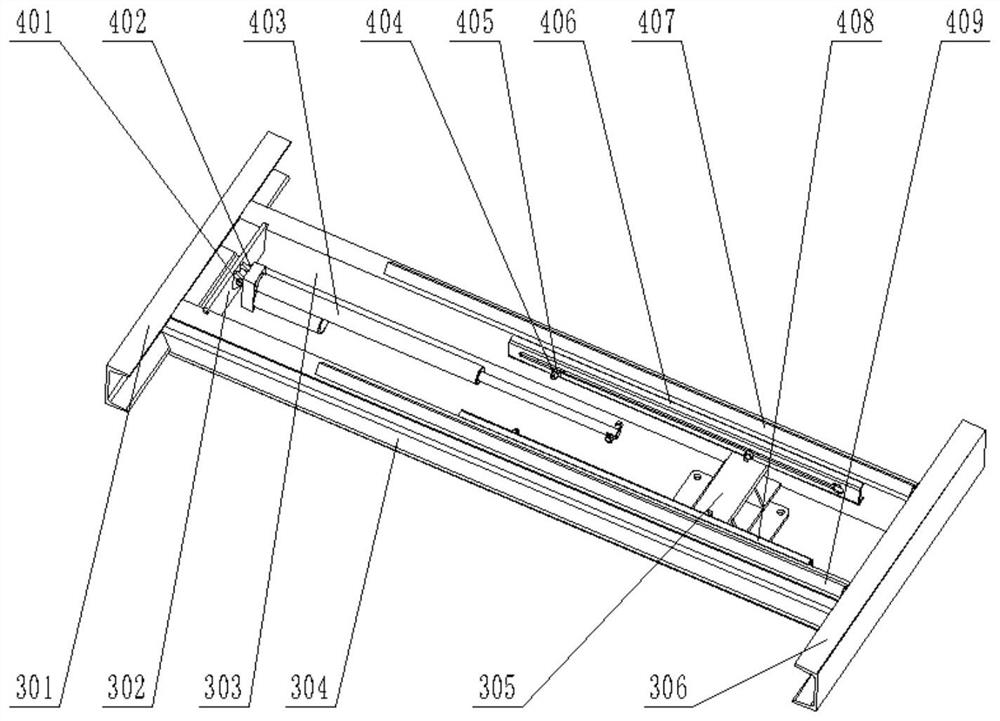

[0078] A fast counterweight system for an electric tractor, the counterweight system is arranged on the body of the electric tractor, and arranged in front, including a power battery pack 1, a power battery mounting frame 2, a carrying frame 3, a sliding adjustment mechanism 4 and a control system.

[0079] Such as figure 1 As shown, v is the forward direction of the counterweight system.

[0080] The power battery pack 1 includes a plurality of battery cells, and the terminals are located on the upper surfaces of the battery cells. Preferably, the power battery pack 1 includes 12 battery cells.

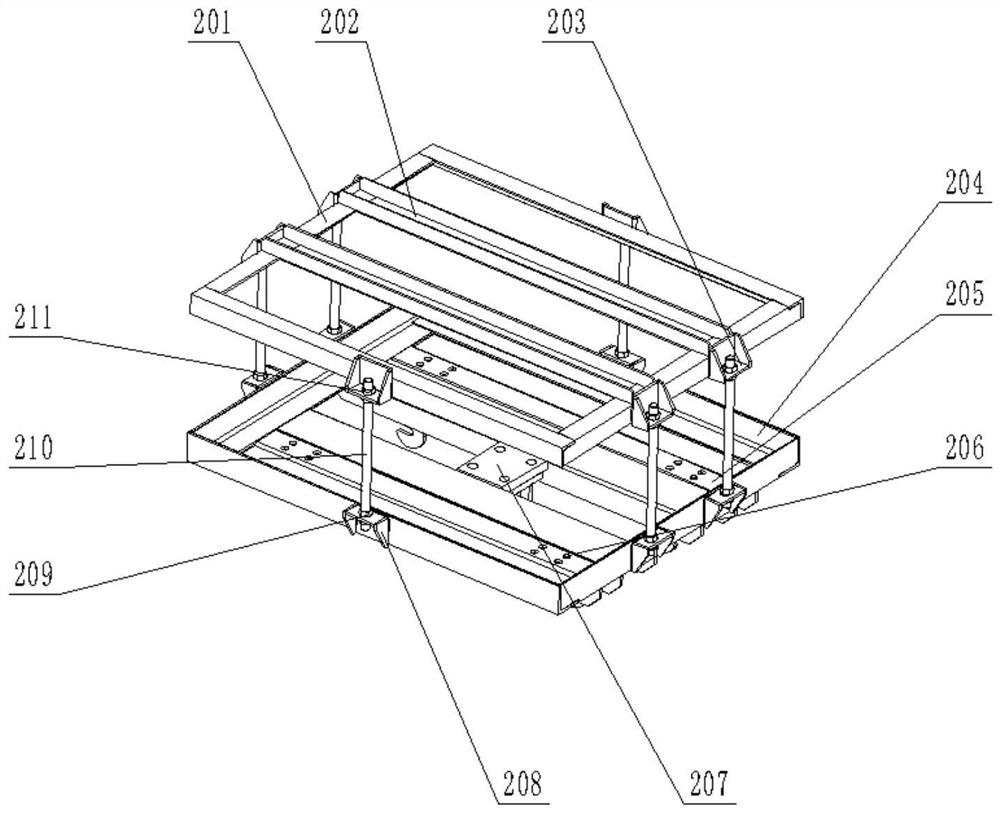

[0081] The power battery mounting frame 2 includes an upper frame 201, an upper rib 202, an upper connector 203, a lower frame 204, a lower rib 205, a "V"-shaped wheel bracket mounting hole 206, an electric push rod mounting seat 207, a lower connection 208, lower mounting nut 209, stud 210 and upper mounting nut 211.

[0082] The upper frame 201 includes four first rods, the leng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com