A high-strength and tough titanium alloy for high temperature 600 °C with good additive manufacturing formability

A technology of additive manufacturing and tough titanium alloy, which is applied in the direction of additive processing, etc., can solve the problems of poor forming performance and low high temperature strength and toughness of additive manufacturing, and achieve poor forming performance and low high temperature damage tolerance of additive manufacturing , the effect of good damage tolerance capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

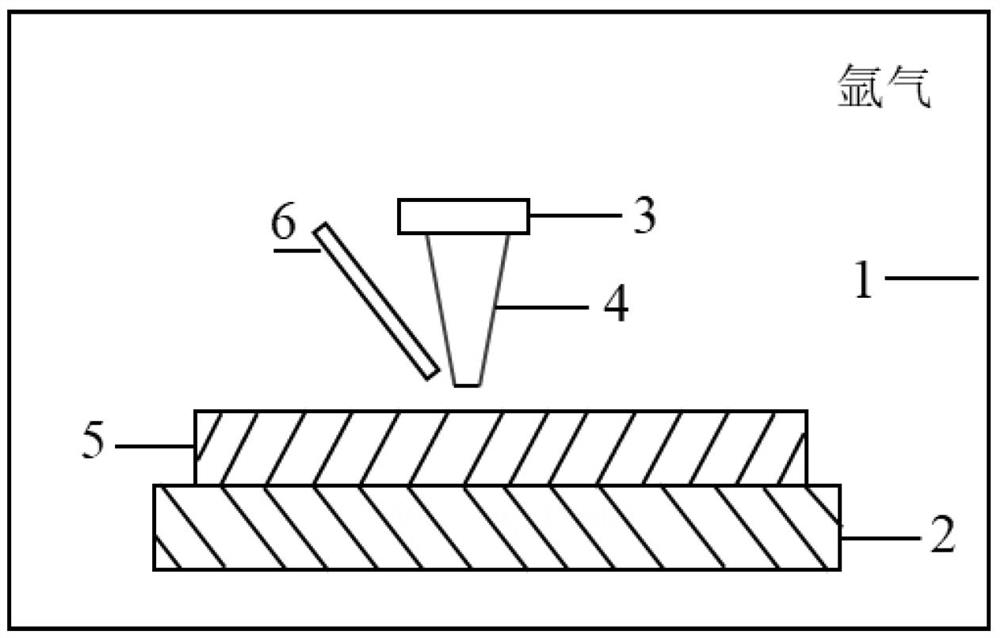

Method used

Image

Examples

Embodiment 1

[0023] Example 1: The mass percent ratio of Al / (V+Mo+Nb+Zr) is 6.8:12

[0024] Example 1 is a high-strength and tough titanium alloy for high temperature 600°C with good additive manufacturing forming properties, which is specifically carried out according to the following steps:

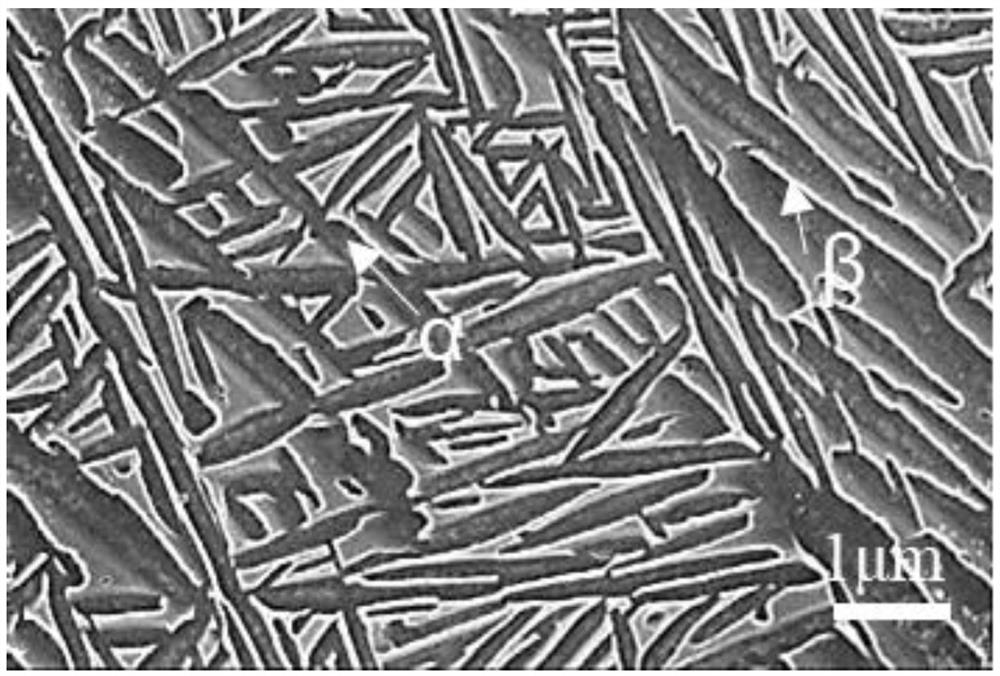

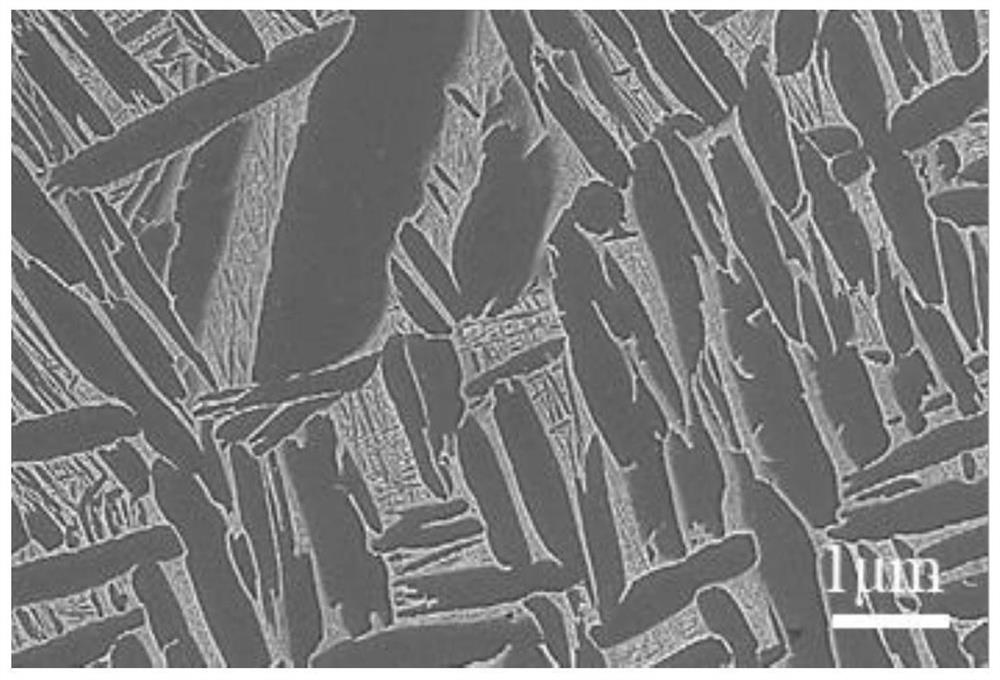

[0025] 1. Composition design and preparation of high-strength and tough titanium alloys for high temperature 600°C: design model 12[Al-Ti based on cluster alloy composition 12 ] (AlTi 2 )+5[Al-Ti 12 Zr 2 ] (AlV 1.2 Mo 0.6 Nb 0.2 ), and the atomic percentage of the titanium alloy composition is obtained as Ti 80.9 al 12.1 V 2.1 Mo 1.1 Nb 0.3 Zr 3.5 (at.%), change the element from atomic percentage to mass percentage Ti 81.2 al 6.8 V 2.3 Mo 2.2 Nb 0.7 Zr 6.8 (wt.%) for component distribution, then ball milling at room temperature for powder mixing, then heating in a vacuum heat treatment furnace to a temperature of 120°C for drying treatment for 8 hours, and cooling to room temperatur...

Embodiment 2

[0028] Example 2: The mass percent ratio of Al / (V+Mo+Nb+Zr) is 6.9:8.7

[0029] Example 2 is a high-strength and tough titanium alloy for high temperature 600°C with good additive manufacturing forming properties, which is specifically carried out according to the following steps:

[0030] 1. Composition design and preparation of high-strength and tough titanium alloys for high temperature 600°C: design model 12[Al-Ti based on cluster alloy composition 12 ] (AlTi 2 )+5[Al-Ti 13 Zr 1 ] (AlV 1.2 Mo 0.6 Nb 0.2 ), and the atomic percentage of the titanium alloy composition is obtained as Ti 82.6 al 12.0 V 2.1 Mo 1.1 Nb 0.4 Zr 1.8 (at.%), change the element from atomic percentage to mass percentage Ti 84.4 al 6.9 V 2.3 Mo 2.2 Nb 0.7 Zr 3.5 (wt.%) for component distribution, then ball milling at room temperature for powder mixing, then heating in a vacuum heat treatment furnace to a temperature of 120°C for drying treatment for 8 hours, and cooling to room temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com