A ti-al-v-zr high temperature resistant, high strength and tough titanium alloy with good additive manufacturing formability and its application

A technology of ti-al-v-zr and tough titanium alloy, which is applied in the direction of additive manufacturing and additive processing, can solve the problems of poor formability, low high-temperature strength, and complex composition of additive manufacturing, and achieve high-temperature strength and toughness improvement , good additive manufacturing formability, and the effect of ensuring the thermal stability of the melt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

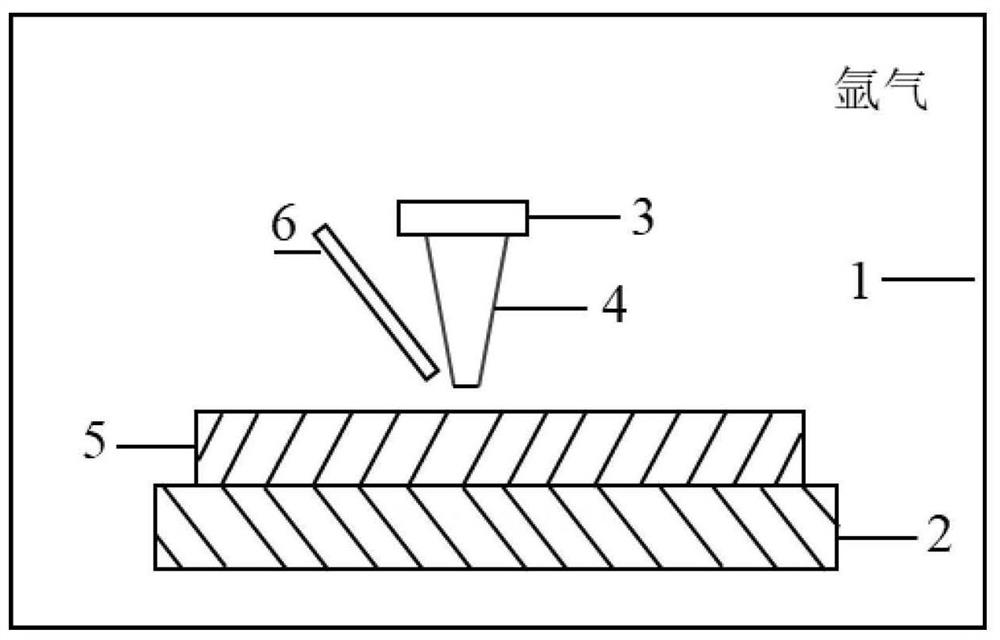

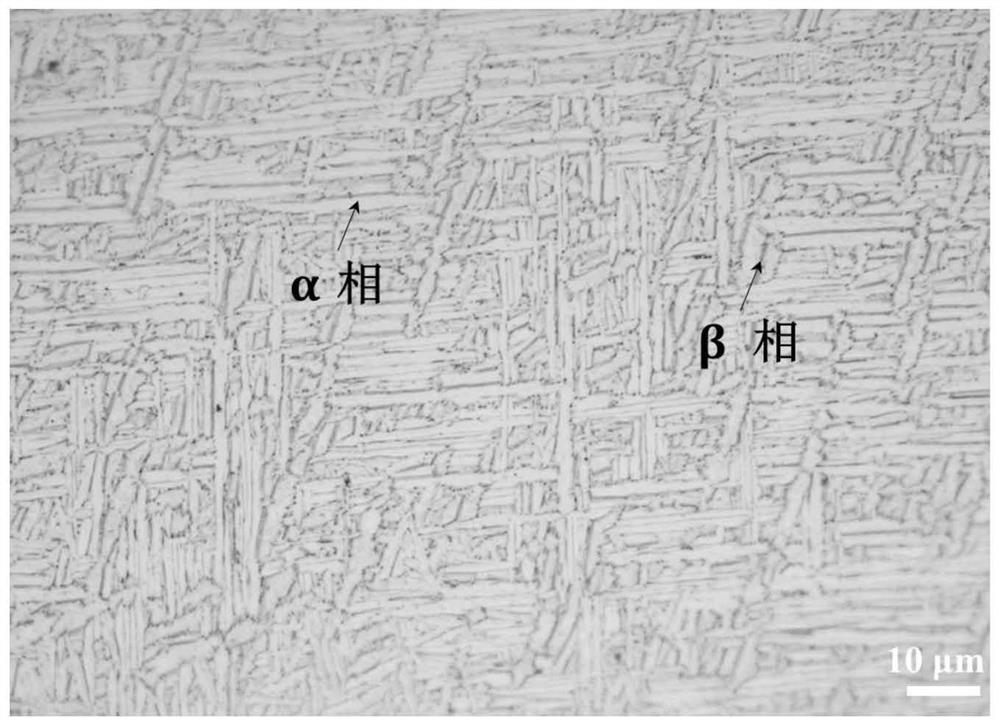

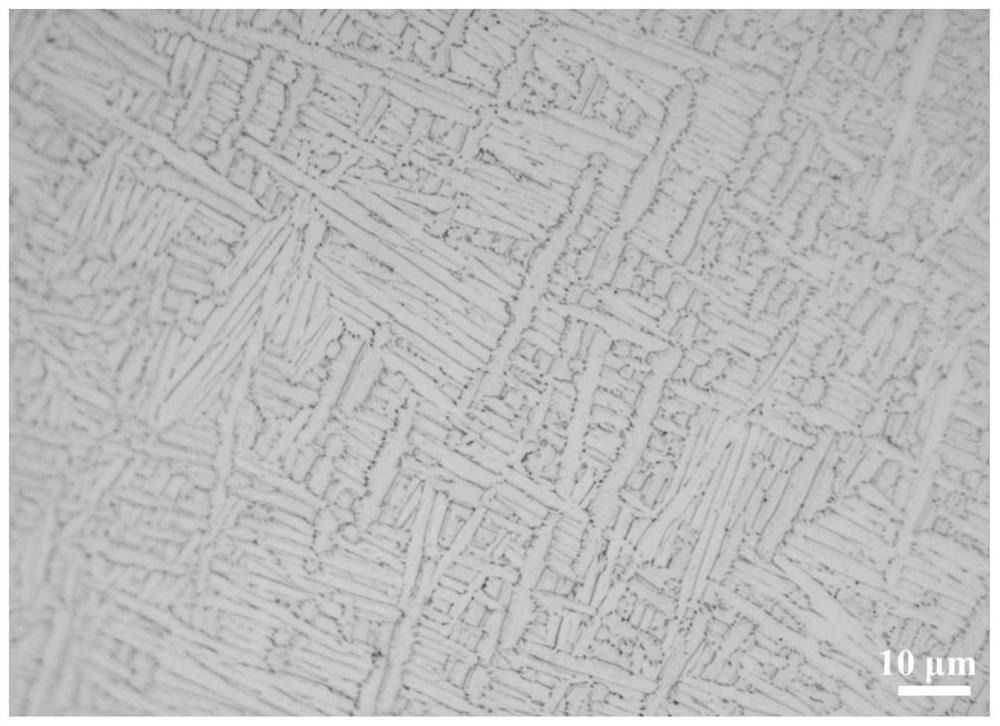

[0021] Embodiment 1 is a Ti-Al-V-Zr high-temperature-resistant high-strength and tough titanium alloy with good additive manufacturing forming properties, specifically carried out according to the following steps:

[0022] 1. Composition design and preparation of Ti-Al-V-Zr high-temperature-resistant high-strength and tough titanium alloy: design model according to cluster alloy composition 15 [Al-Ti 12 ] (AlTi 2 )+2[Al-Ti 12 Zr 2 ](V 3 ), and the atomic percentage of the titanium alloy composition is obtained as Ti 84.8 Al 11.5 V 2.1 Zr 1.4 (at.%), change the element from atomic percentage to mass percentage Ti 87.9 Al 6.8 V 2.4 Zr 2.9 (wt.%) for component distribution, then ball milling at room temperature for powder mixing, then heating in a vacuum heat treatment furnace to a temperature of 120°C for drying treatment for 8 hours, and cooling in the furnace to room temperature to obtain prefabricated dry mixed powder;

[0023] 2. Laser processing: put the prefabri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com