A kind of martensitic heat-resistant steel and its preparation method

A martensitic and heat-resistant steel technology, applied in the field of heat-resistant steel, can solve the problems of high-temperature tempering brittleness, high tempering temperature, and processing difficulties, achieve high strength and hardness, improve high-temperature toughness, and avoid tempering The effect of fire brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] Preparation method of the present invention:

[0037] Firstly, the steel ingot conforming to 15Cr12Ni2Mo2WMnSiVNbN alloy elements is subjected to high-temperature solution treatment in the temperature range of 1150°C to 1050°C, so that the alloy elements are completely dissolved in the austenite, and then high-temperature forging is carried out at a forging temperature of 1050-900°C to achieve refinement. Structure: Quenching treatment is carried out after forging, and the quenching medium is 60°C quenching oil to obtain a martensite-based structure; finally, tempering treatment is carried out: the tempering temperature is 560-610°C, and the temperature is kept for 1.5-4 hours.

[0038] Further, include the following operations:

[0039] 1) The element ratio of the following mass percentages is smelted into steel ingots:

[0040] C: 0.1-0.2%; Cr: 9-14%; Ni: 2.5-3.5%; Mo: 1.0-2.0%; W: 0.5-1.0%; Mn: 0.5-1.0%; Si: 0.10-0.5%; : 0.10~0.5%; Nb: 0.1~0.5%; N: 0.02~0.05%; the ...

Embodiment 1

[0048] New martensitic heat-resistant steel and its preparation process

[0049] The percentages of alloying elements in smelted steel ingots are: C: 0.17; Cr: 14; Ni: 2.8; Mo: 0.7; W: 0.6; Mn: 0.7; Si: 0.2; V: 0.15; . Steel ingot weighs 12Kg. After high-temperature solid solution, high-temperature forging and quenching, the blank is tempered. The tempering temperature is 575°C, and the tempering holding time is 1.5 hours.

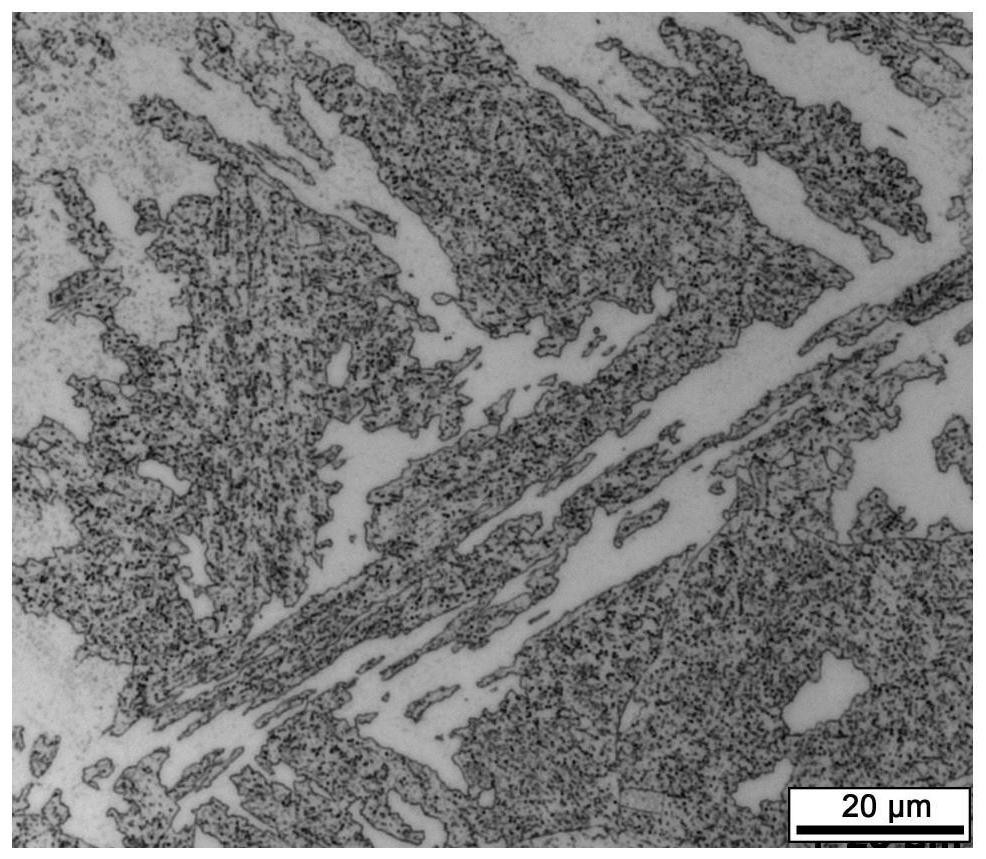

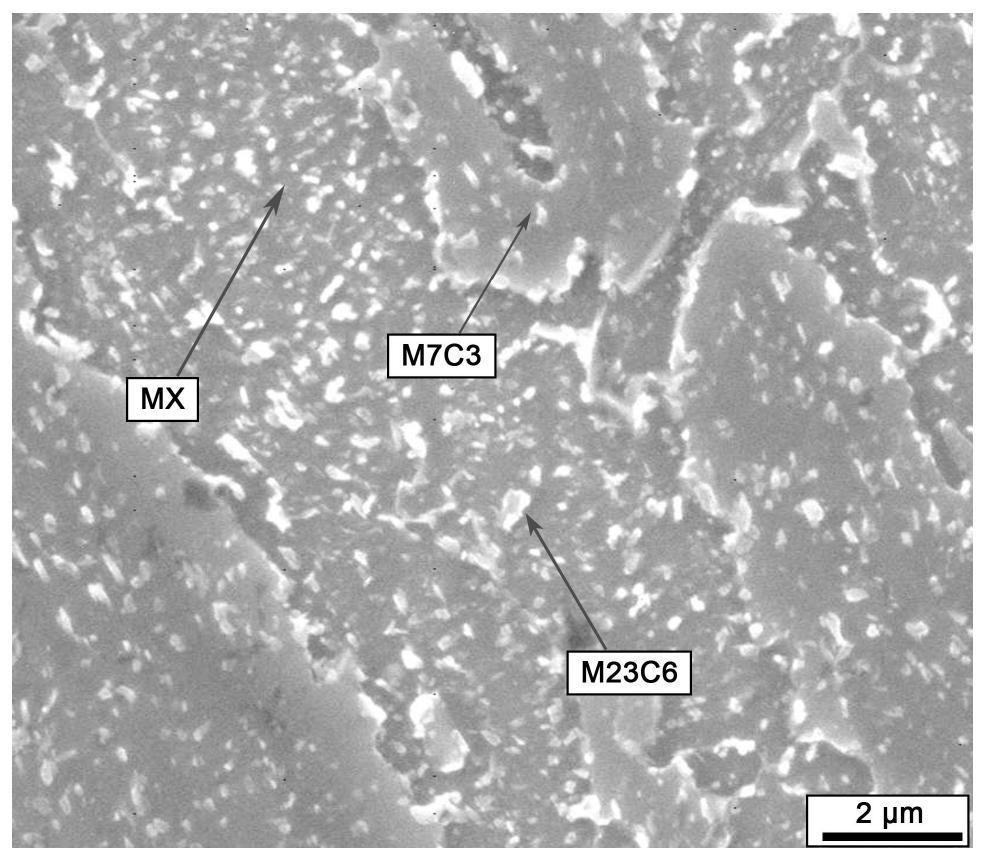

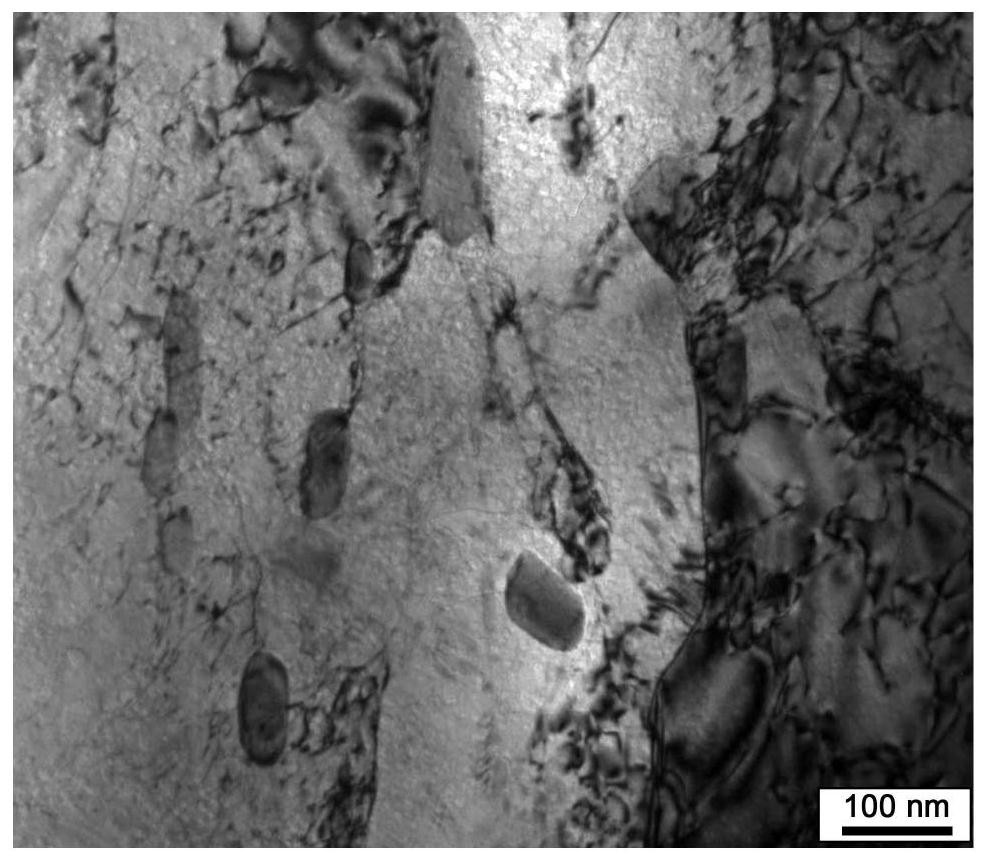

[0050] 3 samples were taken respectively at different parts of the billet, and were observed and analyzed by metallography, scanning electron microscope and transmission electron microscope (results such as figure 1 , figure 2 , image 3 As shown), the carbon and nitrogen compounds precipitated in a large amount in a dispersed state, mainly M2X and M7C3 type carbides, accompanied by a small amount of MX and M6C type carbon and nitrogen compounds; the martensitic lath was recovered to a certain extent (see figure 2 ), which are finely and uniformly ...

Embodiment 2

[0053] New martensitic heat-resistant steel and its preparation process

[0054] The percentage of alloy elements in the smelted steel ingot is: C: 0.11; Cr: 11.3; Ni: 3.2; Mo: 1.3; W: 0.8; Mn: 0.55; Si: 0.12; Steel ingot weighs 15Kg. After high-temperature solid solution, high-temperature forging and quenching, the blank is tempered. The tempering temperature is 595°C, and the tempering holding time is 4 hours.

[0055] Three samples were taken from different parts of the billet, and observed and analyzed by metallography, scanning electron microscope and transmission electron microscope, the number of carbon and nitrogen compounds precipitated was large, in a diffuse distribution state, mainly M2X and M7C3 carbides, accompanied by a small amount of MX And M6C-type carbonitrides; martensite laths have been restored to a certain extent, and they are finely and evenly distributed.

[0056] The mechanical properties of the workpiece in Example 2 were tested, and the impact en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com